My UDS is close to being done. It’s close enough that i have cooked on it twice, and the Q did come out delicious. The main thing needing finished is the charcoal basket, but I’d like to get it operating a little better before I do the finishing touches. Currently I’m getting temps up to 200-205.

The base of the charcoal basket is an industrial air filter lid, 16 inches diameter with about 3 inch high sides, steel. I have the bottom cut out with a piece of perforated stainless steel inserted. I also have eight 1 inch holes cut on the sides. Soon I will be adding more of the perforated stainless to the sides (planning for 12 inches deep, maybe a little more)so I can load it up for long smokes.

I have three 3/4 inch air inlets centered three inches above the bottom of the drum, fed by stainless 3/4 inch nipples, 90 degree bends, with 6 inch risers. The ball valves are full port valves.

My ash pan has 2 inch sides on it, and the charcoal basket has 3 inch legs, so there is a about an inch or so gap between the sides of the pan and basket which is right where the air inlets are pointing.

For my exhaust I’m using the 2 inch port on the lid with a 6 inch riser. Attempting for more heat I removed the 1 inch cap that came on the lid as well. I was able to get my temps to hang around the 225-250 range by cracking the lid on one side and holding it open a little by wedging a screwdriver there, but that is still with all three ball valves wide open.

Most people tend to have no problems maintaining temps with one 3/4 inch ball valve, which tells me my issue is probably air related. Idk if the perforated stainless might be restricting airflow to the coal too much, but I’ve seen some of the charcoal baskets the you can buy pre made or in kits that have solid metal sides and are slotted only at the bottom to let ash drop, so that makes me lean away from the perforated metal being a problem. Maybe I need to cut the sides of the ash pan down to one inch (I doubt this is the problem), but I’m just trying to brainstorm anything affecting my airflow.

Both times i cooked I have used kingsford original. The first time I started the fire by lighting about 6-7 briquettes in the chimney. That seemed to take forever for the rest to light enough to come up to temp, so the second time I used a couple starter cubes. I thought maybe starting with more lit briquettes might help, but I tried keeping the lid cracked quite a bit which got my temp up over 300, and I could see a lot of coals were fired up, then I put the lid back on, but it still just slowly dropped the temps down around 200. So, I don’t know what to try from this point. I know this is throwing a lot of information out there, but any ideas or words of wisdom would be appreciated!

I don’t have any pictures of the charcoal basket right now. I will take some soon. This looks similar to the base I started with, and I have eight 1 inch holes on the sides with the bottom cut out and perforated stainless in its place.

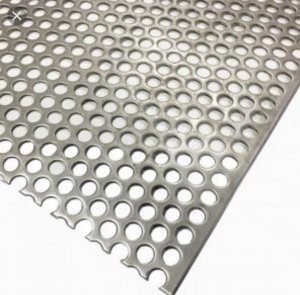

This is what the perforated stainless steel sheet looks like. It’s about 1/8 inch thick with about 3/8 inch holes. When I take some pictures of the actual basket I will update on all the measurements. I’m hoping for some insight from the UDS guru’s on here. Thanks in advance!

The base of the charcoal basket is an industrial air filter lid, 16 inches diameter with about 3 inch high sides, steel. I have the bottom cut out with a piece of perforated stainless steel inserted. I also have eight 1 inch holes cut on the sides. Soon I will be adding more of the perforated stainless to the sides (planning for 12 inches deep, maybe a little more)so I can load it up for long smokes.

I have three 3/4 inch air inlets centered three inches above the bottom of the drum, fed by stainless 3/4 inch nipples, 90 degree bends, with 6 inch risers. The ball valves are full port valves.

My ash pan has 2 inch sides on it, and the charcoal basket has 3 inch legs, so there is a about an inch or so gap between the sides of the pan and basket which is right where the air inlets are pointing.

For my exhaust I’m using the 2 inch port on the lid with a 6 inch riser. Attempting for more heat I removed the 1 inch cap that came on the lid as well. I was able to get my temps to hang around the 225-250 range by cracking the lid on one side and holding it open a little by wedging a screwdriver there, but that is still with all three ball valves wide open.

Most people tend to have no problems maintaining temps with one 3/4 inch ball valve, which tells me my issue is probably air related. Idk if the perforated stainless might be restricting airflow to the coal too much, but I’ve seen some of the charcoal baskets the you can buy pre made or in kits that have solid metal sides and are slotted only at the bottom to let ash drop, so that makes me lean away from the perforated metal being a problem. Maybe I need to cut the sides of the ash pan down to one inch (I doubt this is the problem), but I’m just trying to brainstorm anything affecting my airflow.

Both times i cooked I have used kingsford original. The first time I started the fire by lighting about 6-7 briquettes in the chimney. That seemed to take forever for the rest to light enough to come up to temp, so the second time I used a couple starter cubes. I thought maybe starting with more lit briquettes might help, but I tried keeping the lid cracked quite a bit which got my temp up over 300, and I could see a lot of coals were fired up, then I put the lid back on, but it still just slowly dropped the temps down around 200. So, I don’t know what to try from this point. I know this is throwing a lot of information out there, but any ideas or words of wisdom would be appreciated!

I don’t have any pictures of the charcoal basket right now. I will take some soon. This looks similar to the base I started with, and I have eight 1 inch holes on the sides with the bottom cut out and perforated stainless in its place.

This is what the perforated stainless steel sheet looks like. It’s about 1/8 inch thick with about 3/8 inch holes. When I take some pictures of the actual basket I will update on all the measurements. I’m hoping for some insight from the UDS guru’s on here. Thanks in advance!