Thanks massively to everyone who helped me dial in the "thin blue smoke" on my smoker, especially

cmayna

and

cmayna

and

tallbm

. I learned a ton. I cringe when I look at my old pics of crazy white smoke ruining my fish.

tallbm

. I learned a ton. I cringe when I look at my old pics of crazy white smoke ruining my fish.

Now I'm thinking about somewhat automating the smoking process, because I caught a ton of salmon this year and I'd love to be able to bang out small batches without having to hover around my smoker all day. There's nothing like salmon right out of the smoker, nice and warm, I vote better even than cookies, ha.

I read a post from tallbm

about his automation so I know I'm not the only one interested in this.

tallbm

about his automation so I know I'm not the only one interested in this.

Anyway here's my thoughts, suggestions invited:

I'm a big fan of Arduinos, which for people who don't know are simple tiny and cheap programmable computers that are ideally suited to controlling the heat on a smoker. But actually I use a variant called an ESP32 since it's even smaller and cheaper (around $8 usually) but most importantly has built-in bluetooth and wifi.

They're really easy to control from a phone or tablet, either via bluetooth or wifi.

That makes it possible to easily monitor and control the smoker over the internet, including getting alerts when the temperature has gone up too high (the wood has flamed up) and when the wood has extinguished and I'm not smoking anymore.

Anyway I was wondering what ideal sequence people here would suggest for low temp smoking salmon? I know it varies a bit with the thickness of the meat and amount of brining time and various other factors, but as a starting point I'm thinking something like:

- 1 hour of 110 degrees

- 2 hours of 120 degrees

- 2 hours of 130

- 30 minutes of 140?

I'm thinking that should be flexible in the phone interface, so can have X minutes of Y degrees, followed by X2 minutes of Y2 degrees, etc. Maybe the interface looks like this:

___ minutes off

___ minutes 100

___ minutes 110

___ minutes 120

___ minutes 130

___ minutes 140

alarm

And the user can drag those into whatever order they want, fill in the number of minutes for each, then press start. And looking at the interface during smoking can see how many minutes it's had and how much longer it has to go.

Another thing I'd like it to do is certain watchdog functions. For example my Amaze-N maze smoker still extinguishes, and it's totally possible that that's user error and I'm not giving it enough time to light, but it means I have to check on the smoker pretty often. So I was thinking it would be nice to have a smoke detector. I found a few options, this being the current top contender:

Waveshare Dust Detector Module with Sharp GP2Y1010AU0F

Pros:

- can measure PM2.5, which is (as I understand it) the main component in an "air quality index" (AQI) gizmo. So maybe it could tell me not only whether the smoke source is on or off but also whether I'm getting "thin blue smoke"...

- it can be powered by 3.3 volts, which is what the ESP32 uses (regular Arduinos use 5v).

Cons:

- the mechanism might be especially delicate and get fouled if installed directly in the smoke stream, so will probably need to install it externally.

- is $17

There's also the EIEChip Smoke Sensor Modules aka MQ-2 etc.

Pros:

- cost about $2 and are ubiquitous

- there's a bunch of them each specialized for different gasses. One might be ideal for our purposes.

Cons:

- I don't think can be powered by 3.3v, needs 5v

- lots of complaints of poor calibration, but might be accurate enough for an "is the smoke on?" type measurement

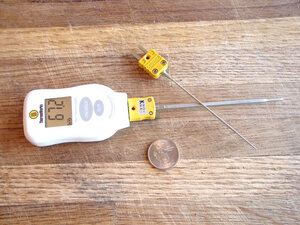

Then just a temprature probe (can be multiple, including ones that go inside the meat) and a relay that works with 3.3v (that relay is enough power for my 600 watts/5 amps of power heating element but of course that's a factor, can always swap the relay or have the relay trip a secondary relay).

I'd probably skip having a local display and interface, using only my phone to check on the temperature, but could easily add one. Or just use one of my ol reliable temperature probes to rule out looking at old data and things like that.

Thoughts? Anything I'm obviously missing? Anything you'd add to make it the perfect salmon smoking automator?

Now I'm thinking about somewhat automating the smoking process, because I caught a ton of salmon this year and I'd love to be able to bang out small batches without having to hover around my smoker all day. There's nothing like salmon right out of the smoker, nice and warm, I vote better even than cookies, ha.

I read a post from

Anyway here's my thoughts, suggestions invited:

I'm a big fan of Arduinos, which for people who don't know are simple tiny and cheap programmable computers that are ideally suited to controlling the heat on a smoker. But actually I use a variant called an ESP32 since it's even smaller and cheaper (around $8 usually) but most importantly has built-in bluetooth and wifi.

They're really easy to control from a phone or tablet, either via bluetooth or wifi.

That makes it possible to easily monitor and control the smoker over the internet, including getting alerts when the temperature has gone up too high (the wood has flamed up) and when the wood has extinguished and I'm not smoking anymore.

Anyway I was wondering what ideal sequence people here would suggest for low temp smoking salmon? I know it varies a bit with the thickness of the meat and amount of brining time and various other factors, but as a starting point I'm thinking something like:

- 1 hour of 110 degrees

- 2 hours of 120 degrees

- 2 hours of 130

- 30 minutes of 140?

I'm thinking that should be flexible in the phone interface, so can have X minutes of Y degrees, followed by X2 minutes of Y2 degrees, etc. Maybe the interface looks like this:

___ minutes off

___ minutes 100

___ minutes 110

___ minutes 120

___ minutes 130

___ minutes 140

alarm

And the user can drag those into whatever order they want, fill in the number of minutes for each, then press start. And looking at the interface during smoking can see how many minutes it's had and how much longer it has to go.

Another thing I'd like it to do is certain watchdog functions. For example my Amaze-N maze smoker still extinguishes, and it's totally possible that that's user error and I'm not giving it enough time to light, but it means I have to check on the smoker pretty often. So I was thinking it would be nice to have a smoke detector. I found a few options, this being the current top contender:

Waveshare Dust Detector Module with Sharp GP2Y1010AU0F

Pros:

- can measure PM2.5, which is (as I understand it) the main component in an "air quality index" (AQI) gizmo. So maybe it could tell me not only whether the smoke source is on or off but also whether I'm getting "thin blue smoke"...

- it can be powered by 3.3 volts, which is what the ESP32 uses (regular Arduinos use 5v).

Cons:

- the mechanism might be especially delicate and get fouled if installed directly in the smoke stream, so will probably need to install it externally.

- is $17

There's also the EIEChip Smoke Sensor Modules aka MQ-2 etc.

Pros:

- cost about $2 and are ubiquitous

- there's a bunch of them each specialized for different gasses. One might be ideal for our purposes.

Cons:

- I don't think can be powered by 3.3v, needs 5v

- lots of complaints of poor calibration, but might be accurate enough for an "is the smoke on?" type measurement

Then just a temprature probe (can be multiple, including ones that go inside the meat) and a relay that works with 3.3v (that relay is enough power for my 600 watts/5 amps of power heating element but of course that's a factor, can always swap the relay or have the relay trip a secondary relay).

I'd probably skip having a local display and interface, using only my phone to check on the temperature, but could easily add one. Or just use one of my ol reliable temperature probes to rule out looking at old data and things like that.

Thoughts? Anything I'm obviously missing? Anything you'd add to make it the perfect salmon smoking automator?

Last edited: