Today I just repaired my second bad probe.

Link to the first one I fixed. http://www.smokingmeatforums.com/t/133733/whats-inside-the-mavrick-732-probes-easy-to-fix

This second probe started going wild during a cook. The pit temp was 225-230 and the probe started to read 350-400 and jumped around so I changed it. Today when I tried it it would read LLL.

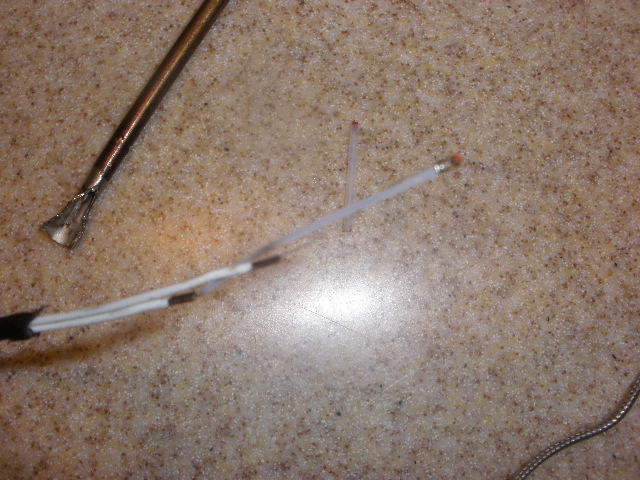

Grinding down the crimp on the tube

Just till you open it enough to spread it open

Then pull it out of the tube. You can see the two crimps and the outer plastic tube under the probe that

came off pulling it out.

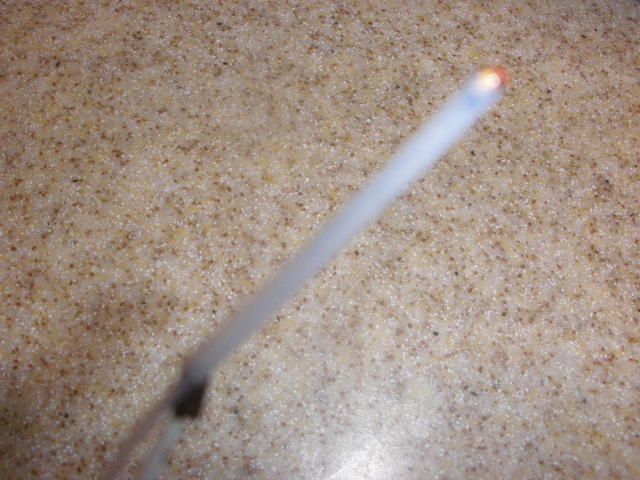

Plugged it back in and it's still LLL. Needle nose pliers and crimp both crimps.

One crimp was tight but the top crimp as soon as I squeezed the pliers it started working.

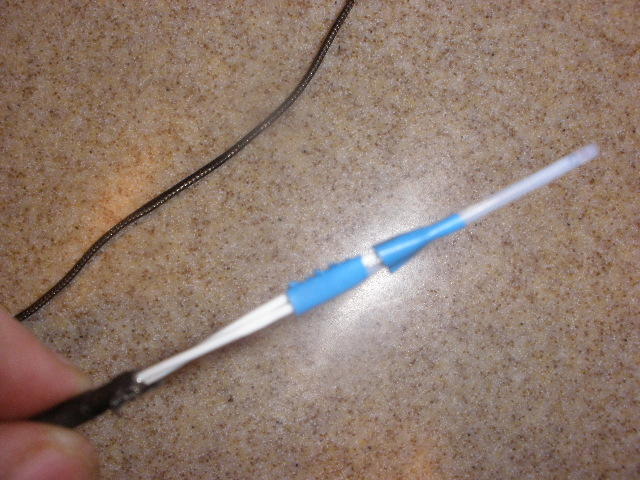

Slip on the outer tube till the tip comes through.

I had to put electrical tape around the crimps because when I tried putting it together with out the tape it read 10* off but with the tape all is good. Just slide it back in and crimp the end back. I will get some heat shrink tubing and seal it.

Both probes read 66 on my counter.

I hope this helps anyone with probe trouble. If you don't want to try to fix bad probes don't trash them send them to me..

Stan

Link to the first one I fixed. http://www.smokingmeatforums.com/t/133733/whats-inside-the-mavrick-732-probes-easy-to-fix

This second probe started going wild during a cook. The pit temp was 225-230 and the probe started to read 350-400 and jumped around so I changed it. Today when I tried it it would read LLL.

Grinding down the crimp on the tube

Just till you open it enough to spread it open

Then pull it out of the tube. You can see the two crimps and the outer plastic tube under the probe that

came off pulling it out.

Plugged it back in and it's still LLL. Needle nose pliers and crimp both crimps.

One crimp was tight but the top crimp as soon as I squeezed the pliers it started working.

Slip on the outer tube till the tip comes through.

I had to put electrical tape around the crimps because when I tried putting it together with out the tape it read 10* off but with the tape all is good. Just slide it back in and crimp the end back. I will get some heat shrink tubing and seal it.

Both probes read 66 on my counter.

I hope this helps anyone with probe trouble. If you don't want to try to fix bad probes don't trash them send them to me..

Stan