- May 27, 2017

- 9

- 11

Hey guys...

A buddy of mine has gotten me interested in sausage making so I jumped at this item I found on OfferUp (a kind of phone app for selling stuff locally like on craigslist)

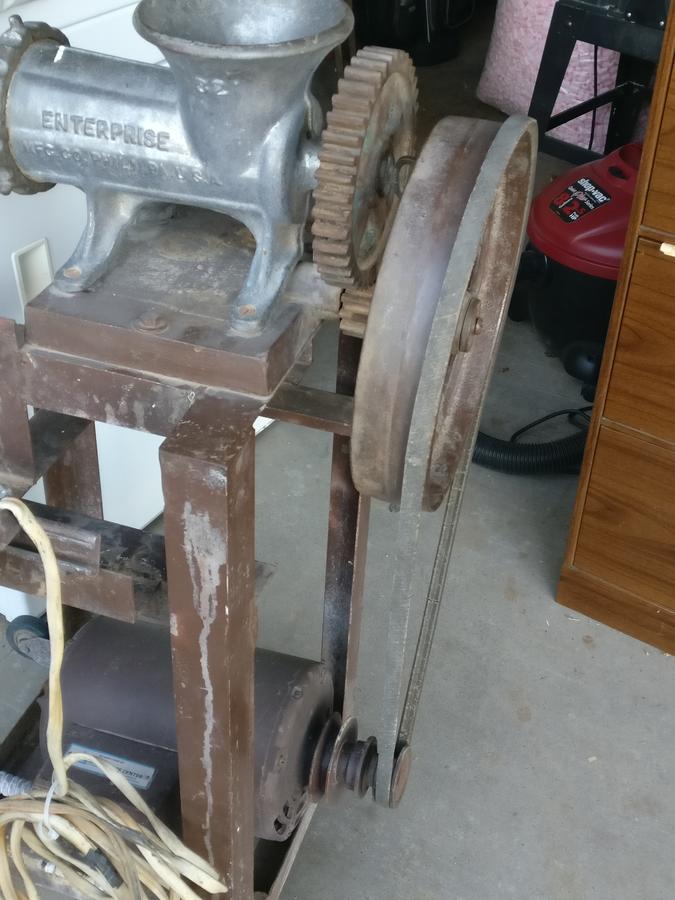

Looks like it's some old home made meat grinding rig with a big motor, a bunch of gears and pulleys, all on a poorly made welded angle iron cart.

Specs:

Enterprise 32 Meat Grinder

Ajax 2hp Motor 1715rpm with a bunch of gears and pulleys

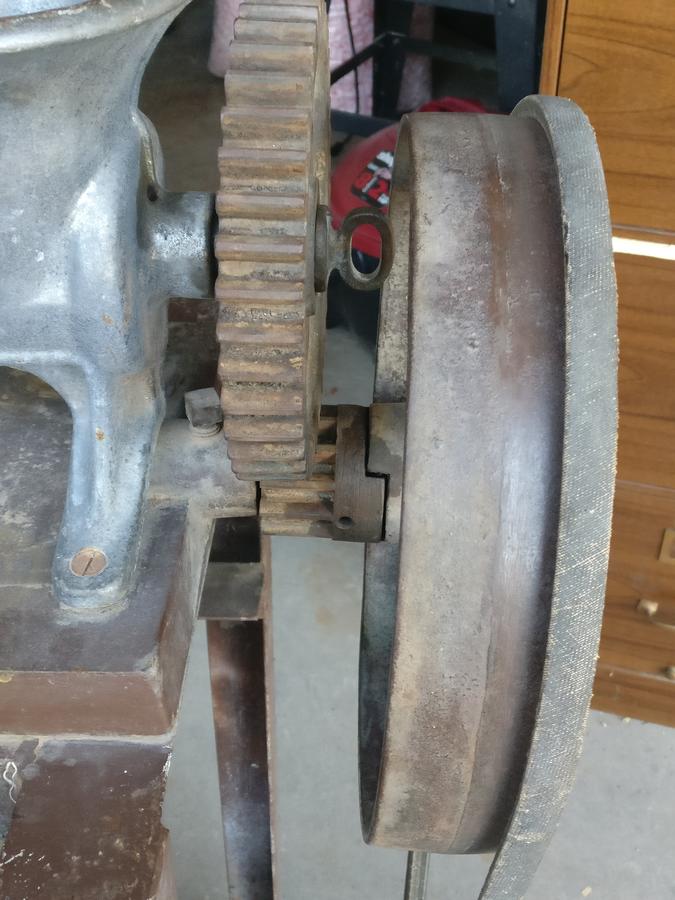

It's got a v-groove pulley wheel on the motor shaft, a large (maybe 12inch) pulley wheel with a mechanical linkage to a much smaller gear wheel that drives about a 6-7" gear wheel that finally turns the grinder.

It came with a set of various grinding plates and 4-blade knives.

The wife approval factor is very low on how kludgy it all looks.

Additionally, it shakes, rattles and rolls like a 1915 Farm-All tractor.. The mechanical linkage is not tight between big belt pulley and the gears. Also, the motor is only attached onto the cart with a couple door hinges one one side... so the motor kinda bounces a little.

Even so, it runs.

When i disconnect everything the motor purrs like a kitten.

OK...

Here are my questions...

It this thing worth messing with?? It looks like the makings of a heavy duty durable meat grinding station... but the plates and knives are a little rusty.. and I'm not sure if that linkage can be improved on.

Also, a 2HP motor sounds like ALOT of power... I was imagining doing this with a much smaller 1/4hp motor that I have. This thing weighs a ton!

Any advice on taking this pile of crap and ending up with a working meat grinder!??

Thx,

Glenn in AZ

A buddy of mine has gotten me interested in sausage making so I jumped at this item I found on OfferUp (a kind of phone app for selling stuff locally like on craigslist)

Looks like it's some old home made meat grinding rig with a big motor, a bunch of gears and pulleys, all on a poorly made welded angle iron cart.

Specs:

Enterprise 32 Meat Grinder

Ajax 2hp Motor 1715rpm with a bunch of gears and pulleys

It's got a v-groove pulley wheel on the motor shaft, a large (maybe 12inch) pulley wheel with a mechanical linkage to a much smaller gear wheel that drives about a 6-7" gear wheel that finally turns the grinder.

It came with a set of various grinding plates and 4-blade knives.

The wife approval factor is very low on how kludgy it all looks.

Additionally, it shakes, rattles and rolls like a 1915 Farm-All tractor.. The mechanical linkage is not tight between big belt pulley and the gears. Also, the motor is only attached onto the cart with a couple door hinges one one side... so the motor kinda bounces a little.

Even so, it runs.

When i disconnect everything the motor purrs like a kitten.

OK...

Here are my questions...

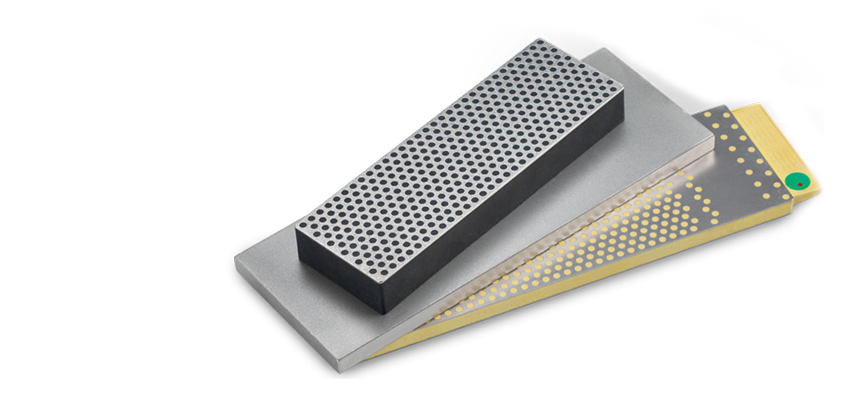

It this thing worth messing with?? It looks like the makings of a heavy duty durable meat grinding station... but the plates and knives are a little rusty.. and I'm not sure if that linkage can be improved on.

Also, a 2HP motor sounds like ALOT of power... I was imagining doing this with a much smaller 1/4hp motor that I have. This thing weighs a ton!

Any advice on taking this pile of crap and ending up with a working meat grinder!??

Thx,

Glenn in AZ