I have both, a 24x48 reverse flow, and a 24x48 traditional flow. My traditional flow is an "open pit" design which means no baffle, no tuning plates. The reverse flow is made from 1/4" steel and has a square firebox with a wood/coal grate, while the traditional flow is made out of 3/8" steel and has a round firebox where you run the fire directly on the floor.

I've had the reverse flow for exactly two years, and I just got the traditional flow four weeks ago, but I have already done multiple cooks on it and put it through its paces.

I know I am probably going to get hate or catch s***t for what I'm about to say because most here seem to be all about the reverse flow, but I don't care...this is my story and I'm just being honest. I have had nothing but problems on my reverse flow, to the point that it drove me to looking for something else. At first I thought it was great, and it appeared to run super clean (nothing but clear heat coming from the stack etc.), then I started trying to cook chicken and noticed it was putting a nasty grey color on the chicken skin. It also uses an insane amount of wood, requiring me to add a 16" long 3-4" diameter split every 15 minutes to maintain a cook chamber temp of 275. I tried everything thinking my problems were user error, or not cleaning it properly, or something with the wood I was using. No matter what I did my problems persisted. I talked to the builder several times and with the exception of the wood consumption, I did get things to improve

a little, but it's still not right and I don't know if it ever will be. After two years of fighting with it, I have come to the conclusion it's an air flow problem with the design that is out of my control. It's actually back with the builder right now as I type this to retrofit it. We'll see if he solves the problem or not. What is interesting to me is that while trying to solve my issues with that cooker I talked to several people and heard from some other reverse flow owners of different brands that had similar problems. That is not to say that all reverse flows will have problems like mine. They definitely don't and I know and have talked with many that are super happy with their reverse flows. But it does seem they are more finicky, and if any of the calculations are off, you may have problems, while traditional flows seem at least a little more forgiving in that regard.

Going through all of that though really got me to thinking, and I think what it really boils down to in choosing what type of cooker is best for you is what type of cooking you like to do. For me, I'm all about Texas style brisket, cooked fat cap up, in the style of Franklin BBQ and all the other great Texas joints. For that reason what I really want is a cooker that cooks from the top down, not the bottom up. So a cooker that uses a baffle like the reverse flow or tuning plates is not going to cook the way I want. I didn't have enough experience to realize that when I bought my reverse flow. Frankly, I didn't know what I was doing.

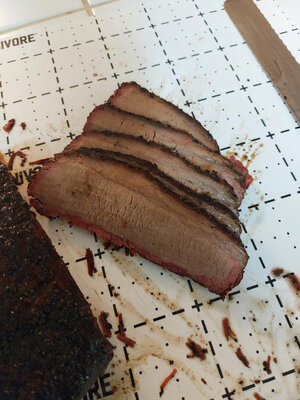

While I have only had the traditional flow for 4 weeks, I've already cooked 3 briskets, 3 racks of ribs, 2 chickens, 2 boneless turkey breasts and a mess of home made sausage, and for me it has been a night and day difference. I haven't had any of the same problems with this pit, and it uses way less wood... about 1 16" long 3-4" diameter split every 35-40 minutes. In addition, while there is a hot spot on the firebox side, it's only about 6-8", and outside of that the rest of the cooking grate runs super even, and I have kept it anywhere from a 5-10 degree difference side to side. To be honest even my reverse flow runs 20 degrees hotter on the firebox side. My traditional flow has so much more air flow that it just renders fat in a completely different way. I also have realized I much prefer the round firebox running the fire directly on the floor, as the curve of the floor makes it easy to sit the splits above the coal bed in a way that encourages air flow without the need for a grate.... and that makes post cook cleaning faster and easier. All of this is however at a cost... My briskets tend to average 10 lb.'s after trimming, and they would take 8 hours like clock work every single time on the reverse flow, but that same 10 lb brisket takes closer to 11-12 hours on the traditional flow. All good though, as I cook my briskets the day before I intend to eat and use an overnight hot hold (in a sous vide bath) so it doesn't really effect me that much.

I'm doing a small BBQ business as a side hustle, and since I can't fit a bigger pit like a 250 through my side yard, I need two 24x48's to have enough capacity. Based on the experience I have had with both of these cookers, I have decided that even if the builder does fix the issue with my reverse flow, I'm going to sell it, as I just prefer the way the traditional flow pit cooks and just how it runs in general, so I'm going to buy a second one exactly like what I just got.

But that's just my story. In order for you to decide what is best for you, I would encourage you to think about what style of cooking you like to do, and whether that type of cooking would be better accomplished with a bottom up cooker, or a top down cooker.

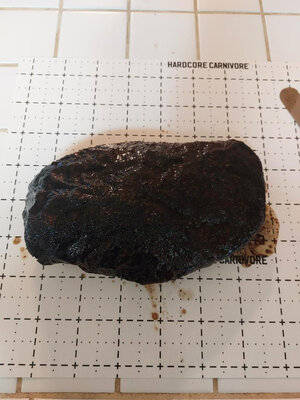

My Reverse Flow

View attachment 640639

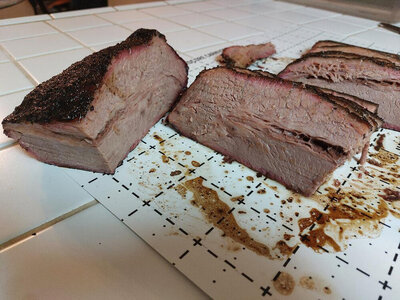

My Traditional Flow

View attachment 640640