[h3]Propane Combustion Characteristics[/h3]

Lower Limit of Flammability

Upper Limit of Flammability

Flash Point

Ignition Temperature in Air

Maximum Flame Temperature

Octane Number

|

2.15

9.60

-156°F

920-1020°F

3595°F

Over 100

|

[h3]

Propane Combustion Characteristics Explained[/h3]

In order for propane to burn, ignite or go through combustion, the criteria listed above must be met. Below are explanations of propane gas combustion characteristics.

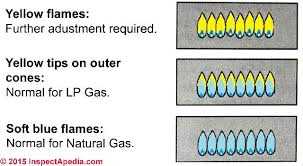

Propane Limits of Flammability - The lower and upper limits of flammability are the percentages of propane that must be present in an propane/air mixture. This means that between 2.15 and 9.6% of the total propane/air mixture must be propane in order for it to be combustible. If the mixture is 2% propane and 98% air, there will not be combustion. If the mixture 10% propane and 90% air, combustion will not occur. Any percentage of propane in a propane/air mixture between 2.15% and 9.6% will be sufficient for propane to burn. However, an improper air/gas mixture can produce

Carbon Monoxide (CO) that is a deadly product of incomplete combustion.

Flash Point - The flash point is the minimum temperature at which propane will burn on its own after having been ignited. This number states that below -156°F, propane will stop burning on it's own. In other words, if the outside air temperature is -155°F, propane will burn on it's own. If the outside air temperature falls to -157°F, propane will no longer burn on it's own. However, if a source of continuous ignition is present, propane will burn below - 156°F.

Ignition Temperate in Air - This number states that propane will ignite if it reaches a temperature between 920-1020°F. If propane is heated up to a temperature between 920 and 1020°F, it will ignite without needing a spark or flame.

Maximum Flame Temperature - A propane flame will not burn hotter than 3595°F.

Octane Number - Without presenting a chemistry lesson, the Octane number of propane being over 100 means that it is a very engine friendly fuel.

Looking at the burner location and inlet sizes..... I'm gonna guess..... The incoming air is mixing with air that has already been burned and also mixing with wood burned air.... both are low in oxygen.... reducing the possibility of complete combustion of the propane gas...

I think the burner area needs to be isolated from all those combusted gasses for it to burn properly... That can be done 2 ways... cut a hole in the floor and lower the burner assembly until the burner ring is flush with the floor so it gets all fresh air from below.... or box in the burner assembly from the burner ring and expose the lower portion to outside air.... I do think the inlet air should be increased also...

Whenever the possibility of already burned air can recirculate, it will screw up the possibility of a clean burn and possibly extinguish a flame or burning wood chips etc....