My wife bought me this for Christmas but couldn't use it till the 25th. She did allow me to season it and do any mods on it. at this time I only did one mod.

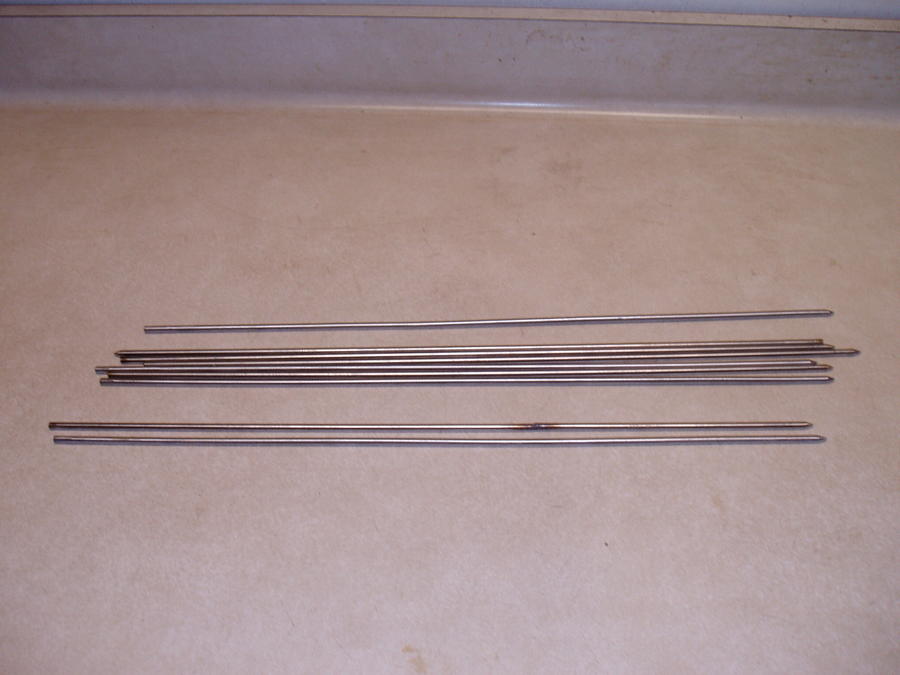

First thing I did was to get 2 10ft pcs of stainless steel rod (3/16) cut 4pcs. at 21.5 in. These are to beef up the existing racks to carry #25 of hanging sausage. the pcs were cut to extend to the center of the vent. Were fastened to the sides of the racks while installed. I used zip ties to fasten.

I removed both sides to cut apart at bottom of upper factory rack. Mark each section to keep together.

I cut here incase future problems arise and I can easily weld the sets back together.

With remaining rod I cut 8 12in. pcs

The rods were all marked 1.5in. from either end. This measurement leaves the width of the facory rail.

Took one rod and placed in vice, heated with torch and bent a 22.5o angle on both ends trying to keep them flat after bending.

Traced out on a board to use as reference for bending remaining rods.

Marked 10 1/16 which was taken from the outside of ziptied rod. This is where the new rails will be welded.

I then placed one pc flush to bottom and marked where the rail intersected each line.

Then cut just below the mark. Proceded to complete each one.

Check each rail on rack to make sure no further bending is required. Each should land on outer edge or just inside.

I then screwed the factory racks to a board for welding. Make sure racks are placed in same order as when taken out of smoker.

Center each rail for welding. When welded I used a block for each side for my gapping.

Spot welded on 4 spots on both top and bottom. As well as the new rails.

When reinstaling back into smoker bottom rack first.

Remaining pcs of rod can be saved or in my case I will use for hanging jerky or smoking shishkibobs. The short pcs can be welded for use.

The

The upper rail I will use mainly for hanging #25 of sausage.

First thing I did was to get 2 10ft pcs of stainless steel rod (3/16) cut 4pcs. at 21.5 in. These are to beef up the existing racks to carry #25 of hanging sausage. the pcs were cut to extend to the center of the vent. Were fastened to the sides of the racks while installed. I used zip ties to fasten.

I removed both sides to cut apart at bottom of upper factory rack. Mark each section to keep together.

I cut here incase future problems arise and I can easily weld the sets back together.

With remaining rod I cut 8 12in. pcs

The rods were all marked 1.5in. from either end. This measurement leaves the width of the facory rail.

Took one rod and placed in vice, heated with torch and bent a 22.5o angle on both ends trying to keep them flat after bending.

Traced out on a board to use as reference for bending remaining rods.

Marked 10 1/16 which was taken from the outside of ziptied rod. This is where the new rails will be welded.

I then placed one pc flush to bottom and marked where the rail intersected each line.

Then cut just below the mark. Proceded to complete each one.

Check each rail on rack to make sure no further bending is required. Each should land on outer edge or just inside.

I then screwed the factory racks to a board for welding. Make sure racks are placed in same order as when taken out of smoker.

Center each rail for welding. When welded I used a block for each side for my gapping.

Spot welded on 4 spots on both top and bottom. As well as the new rails.

When reinstaling back into smoker bottom rack first.

Remaining pcs of rod can be saved or in my case I will use for hanging jerky or smoking shishkibobs. The short pcs can be welded for use.

The

The upper rail I will use mainly for hanging #25 of sausage.