Lots of happy MES owners around. Too bad you has such bad luck to have so many things go bad on your MES.Change door, change wood tray, change element then change out cabinet...I'm done with them and will use a wsm.

MES 40 - Troubleshoot cause of temp reading on display higher than actual temps

- Thread starter hkeiner

- Start date

-

Some of the links on this forum allow SMF, at no cost to you, to earn a small commission when you click through and make a purchase. Let me know if you have any questions about this.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

SmokingMeatForums.com is reader supported and as an Amazon Associate, we may earn commissions from qualifying purchases.

caldersm

Newbie

- Jul 17, 2012

- 2

- 10

Sigmo,

First....great write up with some very interesting analysis..!!

As to the temperature variance....could it be due to the fact that they might not be linearizing the thermocouple millivolts? When we bring in a TC as a direct millivolt reading, we have to use a 2 or 3rd order equation.....if you dont, then you get non-linearity in your input readding. Temperature controllers all do this normally, but maybe they arent compensating for the non-linearity.

Has anyone looked at the control board to see what they are using for the input probe measurement...? Would be interesting to see what reading they are expecting, and if it is a millivolt signal....then to redirect the probe into a arduino or other chip to compensate for the variances.....Just a thought.

I have an analog MES 30 that I got for $115 at Sports Academy, and I used a Omega Temperature Controller with a K-type TC stuck in the rear air slot. I used a SSR with a female plug attached to the controller, and I just set the rotary dial to 100% and let the controller do the action. I found, as you stated earlier in one of your comments, that PID control was too tight, and wouldnt allow smoke, but setting it to On-Off with about 3 degrees of Hysteresis gives great temperature control with LOTS of smoke.

Regards,

Steve

First....great write up with some very interesting analysis..!!

As to the temperature variance....could it be due to the fact that they might not be linearizing the thermocouple millivolts? When we bring in a TC as a direct millivolt reading, we have to use a 2 or 3rd order equation.....if you dont, then you get non-linearity in your input readding. Temperature controllers all do this normally, but maybe they arent compensating for the non-linearity.

Has anyone looked at the control board to see what they are using for the input probe measurement...? Would be interesting to see what reading they are expecting, and if it is a millivolt signal....then to redirect the probe into a arduino or other chip to compensate for the variances.....Just a thought.

I have an analog MES 30 that I got for $115 at Sports Academy, and I used a Omega Temperature Controller with a K-type TC stuck in the rear air slot. I used a SSR with a female plug attached to the controller, and I just set the rotary dial to 100% and let the controller do the action. I found, as you stated earlier in one of your comments, that PID control was too tight, and wouldnt allow smoke, but setting it to On-Off with about 3 degrees of Hysteresis gives great temperature control with LOTS of smoke.

Regards,

Steve

I apologize to everyone for not getting back to this thread in a timely manner.

I haven't actually done too much smoking for a while, either, unfortunately. But tonight, I've got a big pork picnic butt in the smoker in hopes of using some for pulled pork and the rest for some green chile tomorrow.

Anyhow, I don't know what kind of sensor MB is using for either the meat probe or the cabinet temperature sensing. It still seems kind of odd that the meat probe would be so accurate and linear on mine, yet the cabinet temp probe is so far off and so non-linear. It just seems like they'd use the same sensing technology for both.

Like caldersm points out, if they use a thermocouple for the cabinet probe and don't do the proper calculations to convert its millivolt output to temperature, then it'll certainly be wacky. There's a lot to making good readings from a thermocouple. You have to read the temperature at the point where the TC leads connect to the copper wiring of the controller (the cold junction) and then perform the correct CJC (cold junction compensation) and then you also have to deal with the non-linear voltage response of the thermocouple.

But the thing is: With a microcontroller and program, and with modern IC temperature sensors, implementing a very excellent thermocouple reading system is inexpensive when mass produced. Yes, the technology is non-trivial. But once you've designed it and written the code for the controller, the recurring costs to actually manufacture the excellent system are not going to be much.

And again, the fact that the meat probe is so good (within 2 degrees over the whole range I tested) and the cabinet probe is so bad (off by 20 degrees at the high end) is kind of baffling. Maybe they use a thermistor for the meat probe and their designers did well with that, and then they use a thermocouple for the cabinet probe, and their designers didn't appreciate what was necessary to make that work well.

I still have not taken the controller back off of the top of my smoker to see what's inside of it. I've been lazy and just using the smoker occasionally and not worrying too much about it. I just turn it up 20 degrees higher than what I want the cabinet temperature to be, and that makes it pretty close. That limits my high temperature to about 255, but that's actually hotter than I've needed to go anyway.

I haven't actually done too much smoking for a while, either, unfortunately. But tonight, I've got a big pork picnic butt in the smoker in hopes of using some for pulled pork and the rest for some green chile tomorrow.

Anyhow, I don't know what kind of sensor MB is using for either the meat probe or the cabinet temperature sensing. It still seems kind of odd that the meat probe would be so accurate and linear on mine, yet the cabinet temp probe is so far off and so non-linear. It just seems like they'd use the same sensing technology for both.

Like caldersm points out, if they use a thermocouple for the cabinet probe and don't do the proper calculations to convert its millivolt output to temperature, then it'll certainly be wacky. There's a lot to making good readings from a thermocouple. You have to read the temperature at the point where the TC leads connect to the copper wiring of the controller (the cold junction) and then perform the correct CJC (cold junction compensation) and then you also have to deal with the non-linear voltage response of the thermocouple.

But the thing is: With a microcontroller and program, and with modern IC temperature sensors, implementing a very excellent thermocouple reading system is inexpensive when mass produced. Yes, the technology is non-trivial. But once you've designed it and written the code for the controller, the recurring costs to actually manufacture the excellent system are not going to be much.

And again, the fact that the meat probe is so good (within 2 degrees over the whole range I tested) and the cabinet probe is so bad (off by 20 degrees at the high end) is kind of baffling. Maybe they use a thermistor for the meat probe and their designers did well with that, and then they use a thermocouple for the cabinet probe, and their designers didn't appreciate what was necessary to make that work well.

I still have not taken the controller back off of the top of my smoker to see what's inside of it. I've been lazy and just using the smoker occasionally and not worrying too much about it. I just turn it up 20 degrees higher than what I want the cabinet temperature to be, and that makes it pretty close. That limits my high temperature to about 255, but that's actually hotter than I've needed to go anyway.

Sigmo, morning.... Folks have disagreed with me about the MES temps... When all has been evaluated, the incoming air flow mixing with the heat is not homogenized, and the probed portion of the smoker reads colder because of this.... Since I have installed the rheostat on the heating element of my MES 30, and adjust it so it maintains a constant temp in the smoker, the temp on the display and the temp at the exhaust are usually within 5 degrees..... A heat source that is constantly on, will provide a uniform temp throughout the smoker... My observations anyway... Kind of like a side firebox smoker... even temps.... Turning an element on and off will never produce even temps.... especially if there is a constant supply of fresh air intake...

That being said, the average temp, at the grate level where the meat is cooking, is the only temp that is important.... Dave

That being said, the average temp, at the grate level where the meat is cooking, is the only temp that is important.... Dave

Hi, Dave.

Good points.

I don't know if you've read all of my long-winded posts earlier in this thread or not. I admit they're boring.

You're probably right that the position of the sensor in the MES might see some of the air coming into the system and read too cool. On the other hand, because it's right above the heating element, depending on how the incoming air moves over the heater and out of that area, it might read too high when the element is on. There's probably no perfect location for the cabinet sensor probe in such a system, especially if the heater is cycling on and off.

My main curiosity at this point stems from what I measured testing my MES. In mine, carefully controlling things, the temperature reported by the controller is reasonably far away from the temperature that the probe is actually experiencing. So I'm not addressing the variations in temperature throughout the cabinet because I know that won't likely be very even. I was just testing the responses of the probes themselves. And what seems odd to me is that the meat probe is quite accurate (within 2 degrees F at every point I tested). But the cabinet probe in mine appears to be about ten times less accurate.

Some of my posts further up in this thread describe what I've tested on mine, how the tests were performed, and some of my observations and questions.

When you say you installed a rheostat to control the temperature, I'm guessing that you mean you've installed a dimmer circuit or maybe a variac (not as likely). If my assumption there is correct, then what you'll get is constant power to the heater.

That has the advantage that the heater will not cycle on and off. So you'll get no temperature cycling. But as we were talking about above, we can only get away with that if we use an auxiliary smoke generator of some kind. Many of us do, though, so we're free to control the heater any way we want.

The disadvantage of a constant power setup is that you'll have to "ride herd" on the temperature more than if you have a true temperature controller. But that may be of little or no consequence depending on your weather and how much you're planning on babysitting the system during the cooking. I'm lazy, and often like to cook overnight while I sleep. The remote control/readout really makes that fun! But you can still use that even if you're using a separate temperature (or power) control. You just can't make adjustments while laying in bed.

As you point out, what's important is the actual temperature of the cabinet in the area where your meat is. If we can't trust the cabinet probe that comes with the MES, then using a separate probe that you do trust makes a lot of sense.

I'm actually not all that worried about my MES's sensor/display/controller being off as long as I know how far and in what direction it's off. So characterizing mine has proven helpful to me because I know what temperature to set to achieve the actual temperature I want. And knowing that the meat probe is quite accurate gives me the confidence to make good use of it. However, I did run into something today that I wasn't aware of.

I need to test to see if what I think I observed was correct or not. I was finishing my picnic butt this afternoon, and it was reading 199 degrees IT. My reading on here told me that I ought to run it up to 205 IT. So I went out for dinner, and when I got back, it was still reading exactly 199. Hmmm. Could it be that the max temp the meat probe can read is 199? I'm sure the instructions would answer that, but you know how that goes. Does anyone really read them?

I'm also pretty certain that I ran into that when I was testing the calibration of the meat probe, but you know how it is getting old. It's been more than a week, and I've slept since then, so who knows?

I'm also pretty certain that I ran into that when I was testing the calibration of the meat probe, but you know how it is getting old. It's been more than a week, and I've slept since then, so who knows?

If it maxes out at 199 and keeps reading 199 instead of reading "OL" or something to tell us that the reading is off scale, then I need to be aware of that! The butt might have been up to 250 IT, and I'd have never known it! I might lower myself to read the instructions. If I have to. I guess.

Good points.

I don't know if you've read all of my long-winded posts earlier in this thread or not. I admit they're boring.

You're probably right that the position of the sensor in the MES might see some of the air coming into the system and read too cool. On the other hand, because it's right above the heating element, depending on how the incoming air moves over the heater and out of that area, it might read too high when the element is on. There's probably no perfect location for the cabinet sensor probe in such a system, especially if the heater is cycling on and off.

My main curiosity at this point stems from what I measured testing my MES. In mine, carefully controlling things, the temperature reported by the controller is reasonably far away from the temperature that the probe is actually experiencing. So I'm not addressing the variations in temperature throughout the cabinet because I know that won't likely be very even. I was just testing the responses of the probes themselves. And what seems odd to me is that the meat probe is quite accurate (within 2 degrees F at every point I tested). But the cabinet probe in mine appears to be about ten times less accurate.

Some of my posts further up in this thread describe what I've tested on mine, how the tests were performed, and some of my observations and questions.

When you say you installed a rheostat to control the temperature, I'm guessing that you mean you've installed a dimmer circuit or maybe a variac (not as likely). If my assumption there is correct, then what you'll get is constant power to the heater.

That has the advantage that the heater will not cycle on and off. So you'll get no temperature cycling. But as we were talking about above, we can only get away with that if we use an auxiliary smoke generator of some kind. Many of us do, though, so we're free to control the heater any way we want.

The disadvantage of a constant power setup is that you'll have to "ride herd" on the temperature more than if you have a true temperature controller. But that may be of little or no consequence depending on your weather and how much you're planning on babysitting the system during the cooking. I'm lazy, and often like to cook overnight while I sleep. The remote control/readout really makes that fun! But you can still use that even if you're using a separate temperature (or power) control. You just can't make adjustments while laying in bed.

As you point out, what's important is the actual temperature of the cabinet in the area where your meat is. If we can't trust the cabinet probe that comes with the MES, then using a separate probe that you do trust makes a lot of sense.

I'm actually not all that worried about my MES's sensor/display/controller being off as long as I know how far and in what direction it's off. So characterizing mine has proven helpful to me because I know what temperature to set to achieve the actual temperature I want. And knowing that the meat probe is quite accurate gives me the confidence to make good use of it. However, I did run into something today that I wasn't aware of.

I need to test to see if what I think I observed was correct or not. I was finishing my picnic butt this afternoon, and it was reading 199 degrees IT. My reading on here told me that I ought to run it up to 205 IT. So I went out for dinner, and when I got back, it was still reading exactly 199. Hmmm. Could it be that the max temp the meat probe can read is 199? I'm sure the instructions would answer that, but you know how that goes. Does anyone really read them?

If it maxes out at 199 and keeps reading 199 instead of reading "OL" or something to tell us that the reading is off scale, then I need to be aware of that! The butt might have been up to 250 IT, and I'd have never known it! I might lower myself to read the instructions. If I have to. I guess.

texacajun

Meat Mopper

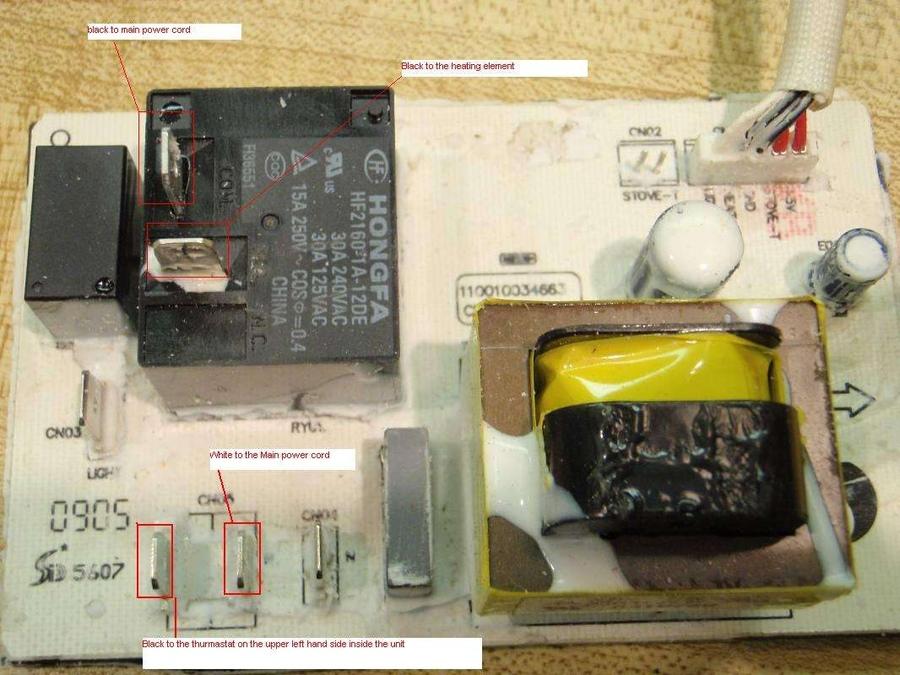

This is a picture of the controller board wich is located on the bottom of the MES. I had to scrap off all the protective sealant so that i could read the board better. Mabe this will help.These MESs are kind of disappointing. It seems that they're not very accurate for whatever reason. I have not had the controller apart. I just put my smoker together and started using it right away. I will take it apart and see what I can find out from looking at things. I would not make any guess as to whether the controllers or the probes are to blame for the strange deviations we're seeing in these units.

Sigmo,

First....great write up with some very interesting analysis..!!

As to the temperature variance....could it be due to the fact that they might not be linearizing the thermocouple millivolts? When we bring in a TC as a direct millivolt reading, we have to use a 2 or 3rd order equation.....if you dont, then you get non-linearity in your input readding. Temperature controllers all do this normally, but maybe they arent compensating for the non-linearity.

Has anyone looked at the control board to see what they are using for the input probe measurement...? Would be interesting to see what reading they are expecting, and if it is a millivolt signal....then to redirect the probe into a arduino or other chip to compensate for the variances.....Just a thought.

I have an analog MES 30 that I got for $115 at Sports Academy, and I used a Omega Temperature Controller with a K-type TC stuck in the rear air slot. I used a SSR with a female plug attached to the controller, and I just set the rotary dial to 100% and let the controller do the action. I found, as you stated earlier in one of your comments, that PID control was too tight, and wouldnt allow smoke, but setting it to On-Off with about 3 degrees of Hysteresis gives great temperature control with LOTS of smoke.

Regards,

Steve

Hey, Steve!

What language is that you're writing in? Is there a translator somewhere? :biggrin:

In a couple of months go to Sam's and try it again. I've had mine for a couple of years and the only thing I did to mine was to change the wood tray and that was a FREE upgrade from Masterbuilt!

JD.

JD.

catpowered

Newbie

Hi, everyone.

Again, I've been away for too long and not attended to the replies that have been posted here.

I do need to take the top controller off and look inside to see if there are any clues as to how they're implementing the reading of the temperature sensors, etc.

For now, though, I have to say that I've been getting good results with the MES40, but I do set the temperature higher than what I actually want, based on the measurements I made so that I'll actually get the desired smoker temperature. That's not that hard to do, and since I haven't needed to go above about 225, I can achieve that.

I am going to do another batch of ribs tomorrow.

Again, I've been away for too long and not attended to the replies that have been posted here.

I do need to take the top controller off and look inside to see if there are any clues as to how they're implementing the reading of the temperature sensors, etc.

For now, though, I have to say that I've been getting good results with the MES40, but I do set the temperature higher than what I actually want, based on the measurements I made so that I'll actually get the desired smoker temperature. That's not that hard to do, and since I haven't needed to go above about 225, I can achieve that.

I am going to do another batch of ribs tomorrow.

This is the problem I have as well with my MES40 Gen2.Mine is off as well, but the other way. I set it at 215 if I want to cook at 225-230.

I want to bump this thread for more info.....

My 2011 MES cuts out at or around 275°

My new 2012 MES runs all the way up to 309°, before the controller realizes it's hit 275° and turns off

The 1st 2012 MES 40 ran all the way up to 329°, before I shut it down. I could smell melted plastic

So, here's my fear....

The New 2012 has a faulty controller and/or the "High Limit Switch" is not working properly

I would assume the High Limit Switch should shut down the unit at or around 275°

I posted this a while back

This table shows the max temp of polyurethane foam to be 250°

Is this really a good choice for a smoker that reaches a temp of 300°+??

Does Masterbuilt post a MATERIAL SAFETY DATA SHEET(MSDS) for their products?

I found a MSDS for another Polyurethane Foam Mfg. that states the melting point at 350° - 375°f

My 2011 MES cuts out at or around 275°

My new 2012 MES runs all the way up to 309°, before the controller realizes it's hit 275° and turns off

The 1st 2012 MES 40 ran all the way up to 329°, before I shut it down. I could smell melted plastic

So, here's my fear....

The New 2012 has a faulty controller and/or the "High Limit Switch" is not working properly

I would assume the High Limit Switch should shut down the unit at or around 275°

I posted this a while back

This table shows the max temp of polyurethane foam to be 250°

Is this really a good choice for a smoker that reaches a temp of 300°+??

Does Masterbuilt post a MATERIAL SAFETY DATA SHEET(MSDS) for their products?

I found a MSDS for another Polyurethane Foam Mfg. that states the melting point at 350° - 375°f

| Insulation Material | Temperature Range | |||

| Low | High | |||

| ([sup]o[/sup]C) | ([sup]o[/sup]F) | ([sup]o[/sup]C) | ([sup]o[/sup]F) | |

| Calcium Silicate | -18 | 0 | 650 | 1200 |

| Cellular Glass | -260 | -450 | 480 | 900 |

| Elastomeric foam | -55 | -70 | 120 | 250 |

| Fiberglass | -30 | -20 | 540 | 1000 |

| Mineral Wool | 0 | 32 | 1000 | 1800 |

| Phenolic foam | 150 | 300 | ||

| Polyisocyanurate or polyiso | -180 | -290 | 150 | 300 |

| Polystyrene | -50 | -60 | 75 | 165 |

| Polyurethane | -210 | -350 | 120 | 250 |

Last edited:

smokingrk

Smoke Blower

The only thing I can add to this info is that I realized yesterday while testing, the temps the top half section of the smoker (2[sup]nd[/sup] GEN 40” MES) ran about 20+ degrees hotter than bottom half, when the element was on.

I’m now leaning towards a convection / air flow issue correction.

Ordered additional MAV to get a probe on each shelf and will re-run when I replace controller from MB, understanding that we’ll see a few degrees delta between probes as Sigmo noted, but hoping controller will correct the temp control issue, then work on the top half heat issue.

Smoker Set at 250, controller temp reading 232, bottom racks around 278, 275, top rack already at 302, and element was still on...did not want to let this go more, although during seasoning I may have over done it and not noticed since my external thermometer was hanging on second shelf from bottom, reading 310, so top half must have been at 330+, top plastic on door shows two cracks.

I’m now leaning towards a convection / air flow issue correction.

Ordered additional MAV to get a probe on each shelf and will re-run when I replace controller from MB, understanding that we’ll see a few degrees delta between probes as Sigmo noted, but hoping controller will correct the temp control issue, then work on the top half heat issue.

Smoker Set at 250, controller temp reading 232, bottom racks around 278, 275, top rack already at 302, and element was still on...did not want to let this go more, although during seasoning I may have over done it and not noticed since my external thermometer was hanging on second shelf from bottom, reading 310, so top half must have been at 330+, top plastic on door shows two cracks.

My door cracked too, but it was on the bottom

It's crazy, that your 2012 MES acts exactly like mine

Makes me wonder if the rest of them are acting correctly???

Yesterday, I ran another test

Set the controller to 275°

Placed Maverick probes on top shelf

They read 295° & 300° for most of the day

Not the 329° that my 1st 2012 MES 40 got up to

It's crazy, that your 2012 MES acts exactly like mine

Makes me wonder if the rest of them are acting correctly???

Yesterday, I ran another test

Set the controller to 275°

Placed Maverick probes on top shelf

They read 295° & 300° for most of the day

Not the 329° that my 1st 2012 MES 40 got up to

smokingrk

Smoke Blower

I can retry the test to see if the temp goes above the 310 mark on top racks and will have to keep a close watch.

If I get to it today I'll post a quick note. Otherwise I'll wait to replace controller and test all at once.

If I get to it today I'll post a quick note. Otherwise I'll wait to replace controller and test all at once.

I don't know if it's the controller or a temp sensor inside

When I called customer service at Masterbuilt for the same issue, they wanted to send me a new cabinet

I had to cut off the cord and the name plate, and send them in

In-turn, they would send me a new cabinet.

The process would take 2 weeks

I declined, and decided to return it to SAMS for a new one instead

When I called customer service at Masterbuilt for the same issue, they wanted to send me a new cabinet

I had to cut off the cord and the name plate, and send them in

In-turn, they would send me a new cabinet.

The process would take 2 weeks

I declined, and decided to return it to SAMS for a new one instead

That's what I'd have done. Let MB fix it themselves. Let us know how the replacement unit is.

I hope MB gets the new ones straightened out.

Phoned in.

I hope MB gets the new ones straightened out.

Phoned in.

SmokingMeatForums.com is reader supported and as an Amazon Associate, we may earn commissions from qualifying purchases.

Similar threads

- Replies

- 11

- Views

- 655

- Replies

- 28

- Views

- 9K

- Replies

- 9

- Views

- 7K

- Replies

- 6

- Views

- 6K

- Replies

- 22

- Views

- 7K

- Replies

- 2

- Views

- 6K

SmokingMeatForums.com is reader supported and as an Amazon Associate, we may earn commissions from qualifying purchases.

Hot Threads

-

Featured First Smoked Chili

- Started by mneeley490

- Replies: 20

- Chili, Soups, and Stews

-

Not Sure What To Call It?!

- Started by Rafter H BBQ

- Replies: 14

- Blowing Smoke Around the Smoker.

-

Pop's Brine time for various meats and poultry

- Started by bilbo56

- Replies: 14

- General Discussion

-

First go on making bacon

- Started by Blue Collar Pit Boss

- Replies: 13

- Hot Smoked Bacon