- Apr 16, 2015

- 21

- 20

I started a thread a few months ago titled "MES 30 Help" and as a result of all the great inputs I received I purchased an Auber PID for the MES 30 and everything works great.

Recently I was given a MES 40 because the original owner didn't like it because it wouldn't maintain a set temperature. I told him about the Auber PID but he wasn't interested. So I modified the MES 40 to make it compatible with my PID. I disconnected and stowed the existing connections at the two heating element terminals and connected a new power cord directly to the heating element terminals plus a chassis ground. I created the new power cord by cutting one end of of a 10" outdoor extension cord. (NOTE- In doing so I disconnected the MES 40 high temp limit switch which I'm OK with. Basically the Auber is a very expensive high temp limit switch that custs power when the desired temp is reached as opposed to an high temp threshold like the310 degree MES limit switch). The Auber also has an alarm function should some high threshold temp be exceeded (e.g.- grease fire). When I( finished the wiring mod I replaced the small insulated panel cover that covers the wiring for the heater element terminals.

Yesterday I turned on the MES 40 for the first time using the Auber PID. It worked perfectly and maintained the internal temp of 275 degree (+/- 3 degree) for about 3 hours. However, I noticed that the small insulated panel cover was "extremely" hot to the touch. I turned off the PID and allowed to MES 40 to cool down. Then I removed the small panel cover to inspect the wiring. Everything appeared to be normal. No melting, discoloration or brittleness in any of the new connectors or wiring.

Questions-

1. Is it normal for the panel that covers the heating element terminals to become too hot to touch?

2. If it's not normal- what is causing the temp to get so high? Faulty heating element? Wiring mod? Something else?

3. If it is normal- Are there any special precautions I need to take with the modified wiring? Small thermal blanket between the back wall of the MES and the heating element terminals? High temp tape wrap around the power cord wires that are inside the panel area? Remove the insulated panel cover and leave the heating element terminals open? Other?

All thoughts appreciated. I'm getting ready to do another MES 40 test with the PID and I plan to leave a temp probe inside the terminal wiring area with the cover on to see how hot it gets in there and I'll post an update here when available.

UPDATE-

Modification-

a. All connections look tight to me.

b. I used an outdoor extension cord for the new power cord. It is 10 foot, 3-wire, stranded-copper, 16 gauge wire rated for 13 amps and 1825 watts.

c. I used foil tape to secure the cord to the back of the smoker as a strain relief.

Performance-

a. The initial test was at 280 degrees for 3 hours. ( I know- 275 is the maxed rated temp).

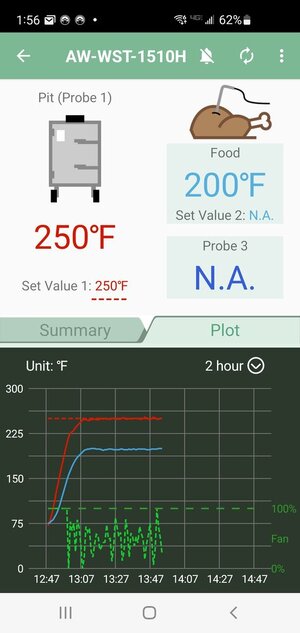

b. the second test was 250 degrees for 3 hours. The wiring panel temp stabilized at 200 degrees (see screenshot below).

Recently I was given a MES 40 because the original owner didn't like it because it wouldn't maintain a set temperature. I told him about the Auber PID but he wasn't interested. So I modified the MES 40 to make it compatible with my PID. I disconnected and stowed the existing connections at the two heating element terminals and connected a new power cord directly to the heating element terminals plus a chassis ground. I created the new power cord by cutting one end of of a 10" outdoor extension cord. (NOTE- In doing so I disconnected the MES 40 high temp limit switch which I'm OK with. Basically the Auber is a very expensive high temp limit switch that custs power when the desired temp is reached as opposed to an high temp threshold like the310 degree MES limit switch). The Auber also has an alarm function should some high threshold temp be exceeded (e.g.- grease fire). When I( finished the wiring mod I replaced the small insulated panel cover that covers the wiring for the heater element terminals.

Yesterday I turned on the MES 40 for the first time using the Auber PID. It worked perfectly and maintained the internal temp of 275 degree (+/- 3 degree) for about 3 hours. However, I noticed that the small insulated panel cover was "extremely" hot to the touch. I turned off the PID and allowed to MES 40 to cool down. Then I removed the small panel cover to inspect the wiring. Everything appeared to be normal. No melting, discoloration or brittleness in any of the new connectors or wiring.

Questions-

1. Is it normal for the panel that covers the heating element terminals to become too hot to touch?

2. If it's not normal- what is causing the temp to get so high? Faulty heating element? Wiring mod? Something else?

3. If it is normal- Are there any special precautions I need to take with the modified wiring? Small thermal blanket between the back wall of the MES and the heating element terminals? High temp tape wrap around the power cord wires that are inside the panel area? Remove the insulated panel cover and leave the heating element terminals open? Other?

All thoughts appreciated. I'm getting ready to do another MES 40 test with the PID and I plan to leave a temp probe inside the terminal wiring area with the cover on to see how hot it gets in there and I'll post an update here when available.

UPDATE-

Modification-

a. All connections look tight to me.

b. I used an outdoor extension cord for the new power cord. It is 10 foot, 3-wire, stranded-copper, 16 gauge wire rated for 13 amps and 1825 watts.

c. I used foil tape to secure the cord to the back of the smoker as a strain relief.

Performance-

a. The initial test was at 280 degrees for 3 hours. ( I know- 275 is the maxed rated temp).

b. the second test was 250 degrees for 3 hours. The wiring panel temp stabilized at 200 degrees (see screenshot below).

Attachments

Last edited: