Good morning all, I have run a couple of smokes through my new reverse flow build. A little background: I built a 3' x 6' cylinder reverse flow. The firebox is big as well coming in at 36" long x 30" tall x 24" deep.

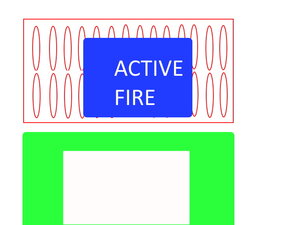

I noticed on the last smoke that I couldnt get the fire up past 200. I thought about it for a minute and came up with this. On the last smoke I built a fire but it wasnt gigantic. It is hard to cover a grate that large entirely with a bed of coals. There are some gaps in front of and behind the grate and all around the fire. Air could flow straight through an area without coals and the smoker would essentially be pulling cold air through without ever making the fire hotter. I was thinking about covering up the edges and the area on the grate where there isnt usually a fire to force the air to flow past the coals as it should. I included a picture to illustrate my idea. The red area is the grate, the blue area is the fire area, the green thing is a piece of 1/4" steel cut to fit and sits on top of the grate.

Am I on to a legitimate problem here or do I just need to man up and build a fire that covers the grate entirely?

I noticed on the last smoke that I couldnt get the fire up past 200. I thought about it for a minute and came up with this. On the last smoke I built a fire but it wasnt gigantic. It is hard to cover a grate that large entirely with a bed of coals. There are some gaps in front of and behind the grate and all around the fire. Air could flow straight through an area without coals and the smoker would essentially be pulling cold air through without ever making the fire hotter. I was thinking about covering up the edges and the area on the grate where there isnt usually a fire to force the air to flow past the coals as it should. I included a picture to illustrate my idea. The red area is the grate, the blue area is the fire area, the green thing is a piece of 1/4" steel cut to fit and sits on top of the grate.

Am I on to a legitimate problem here or do I just need to man up and build a fire that covers the grate entirely?