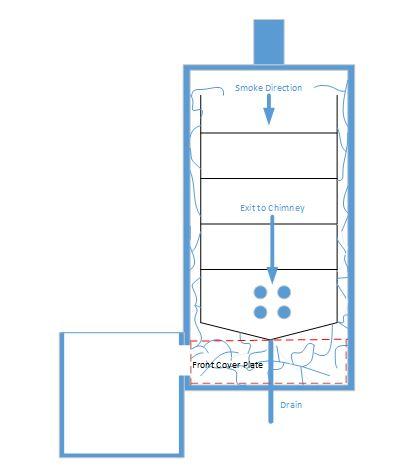

I have been reading this site for a while now and trying to learn as much as I can. I found another site that goes thru a very well documented build of a insulated cabinet reverse flow build - done by bbq engineer. I want to take this concept and add a offset firebox. I put together a simple drawing and I would like to get feedback if this would work vs. having the firebox at the bottom of the cabinet as in typical designs.

The design is to have insulated walls for the cabinet and smoker. I was thinking of not insulating the top of the firebox, as this would allow for a great place to warm extra pieces of wood prior to burn.

I can't start on this build for a minimum of 8 weeks, so I will be researching and designing until I can start.

--geoff

The design is to have insulated walls for the cabinet and smoker. I was thinking of not insulating the top of the firebox, as this would allow for a great place to warm extra pieces of wood prior to burn.

I can't start on this build for a minimum of 8 weeks, so I will be researching and designing until I can start.

--geoff