This is my new braunfels smoker I started out with . When I first found this site I seen lots of things I could do to it for a better smoke.

I have put gaskets on the fire box and cooking area,all so seen the clamps for both. FB And Cooking area .for a good seal .

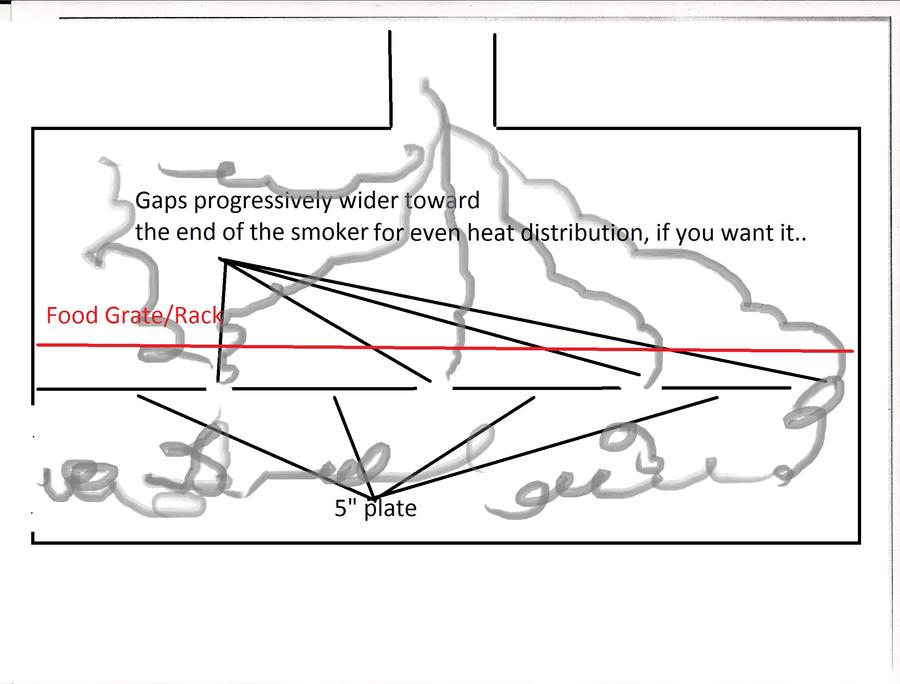

but I didn't stop there I added 1/4" tuning plates to help with the heat along with a water pan

plus went ahead and added a pipe from smoke stack to one inch above the cooking grade. I blocked about 1/2 of the opening from the FB to cooking area too

we build a basket for the charcoal or wood

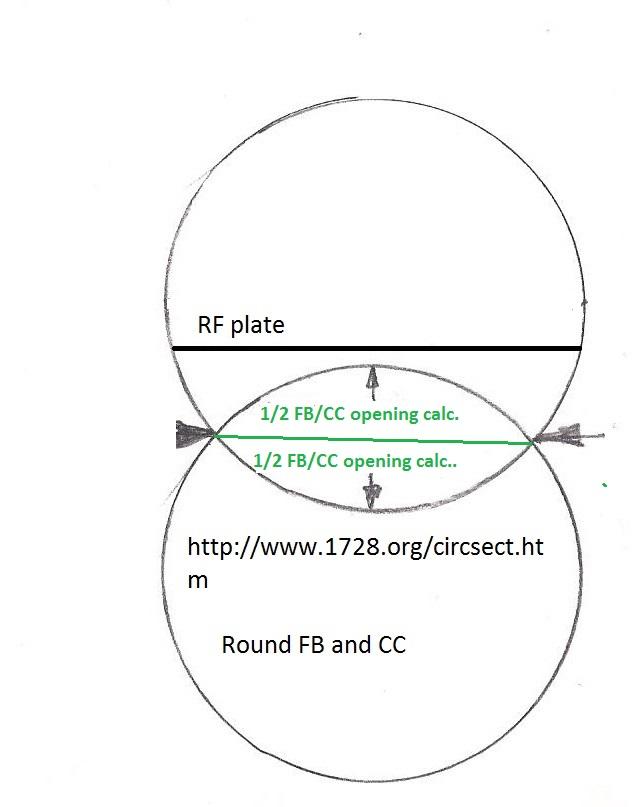

didnt stop there went to harbor freight Got new wheels for it too . I still wasn't happy still so I took it from a direct flow to a reverse flow

well here is my question some days I can get really good temperature and evenly too 210 ,205 so that's good but shouldn't it be able to get hotter then that? I burn

yes that's Hickory Lump and kingsford gets nice and hot

![GALLERY]](data:image/gif;base64,R0lGODlhAQABAIAAAAAAAP///yH5BAEAAAAALAAAAAABAAEAAAIBRAA7) now the other question is flow of the fire should be going in the smoker right ? Do I need a bigger smoke stack ?am I doing something wrong? Thank you for your help .

now the other question is flow of the fire should be going in the smoker right ? Do I need a bigger smoke stack ?am I doing something wrong? Thank you for your help .

Some q pics

Some q pics