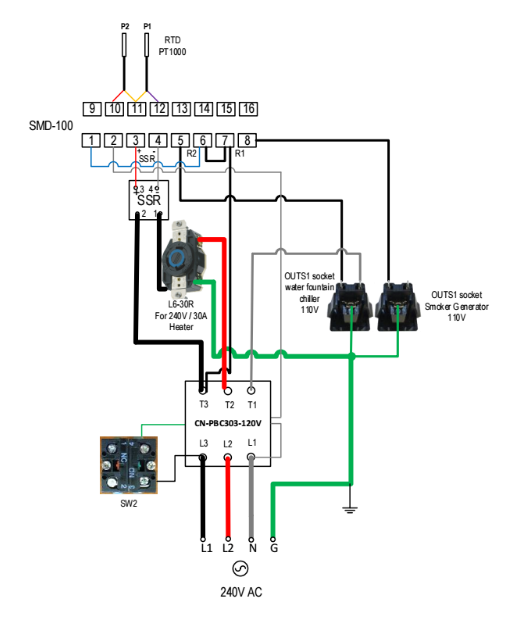

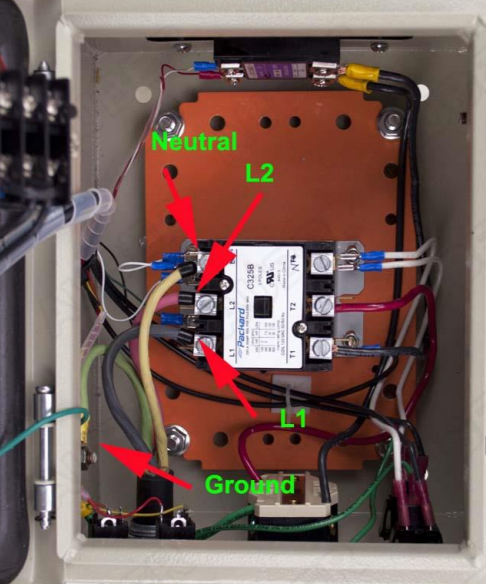

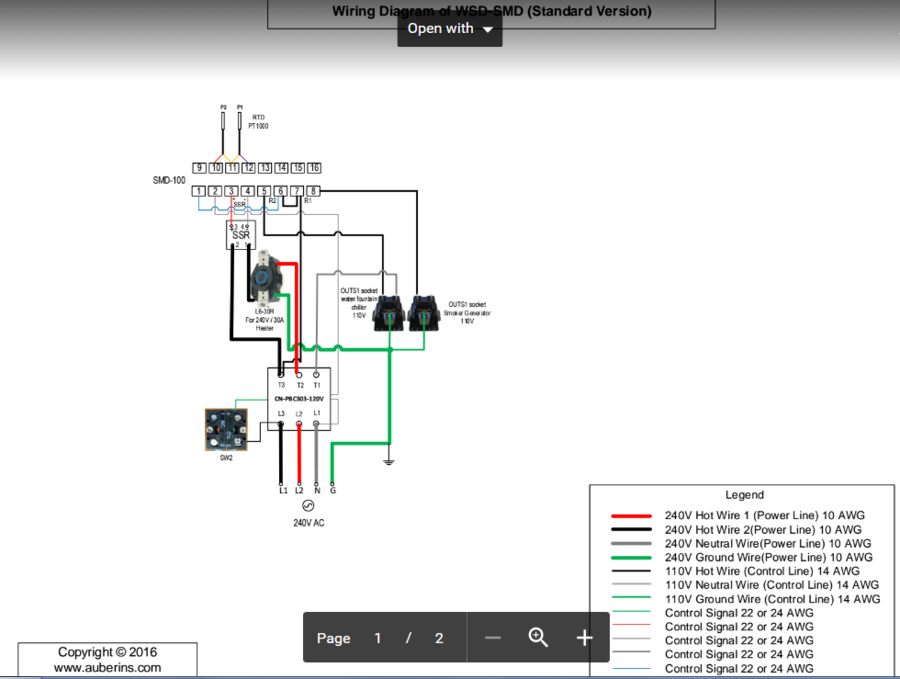

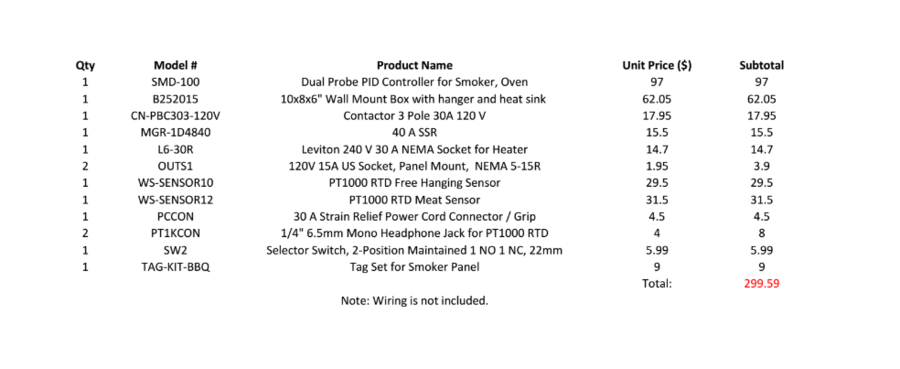

Here are the wiring instructions directly from Auberinsno.. the MES is not the one I use... I have a smokehouse (not in signature) ... it has 2 - 220v elements out of an old oven... I only use a SSR (with heat sync) ... no contacter .... I am interested in seeing how your going to wire this as my thinking is the conactor will work against the SSR ?? meaning the contactor is ether on 100% full power or off... The SSR keeps turning on and off many times a minute to hold at set temp... The contactor (from what I understand) stays on until it gets to set temp then turns off... resulting in temps rising above and falling below set temps (like an oven) ... PLease correct me if i'm wrong ...

Last edited: