Smokinribsbbq

Fire Starter

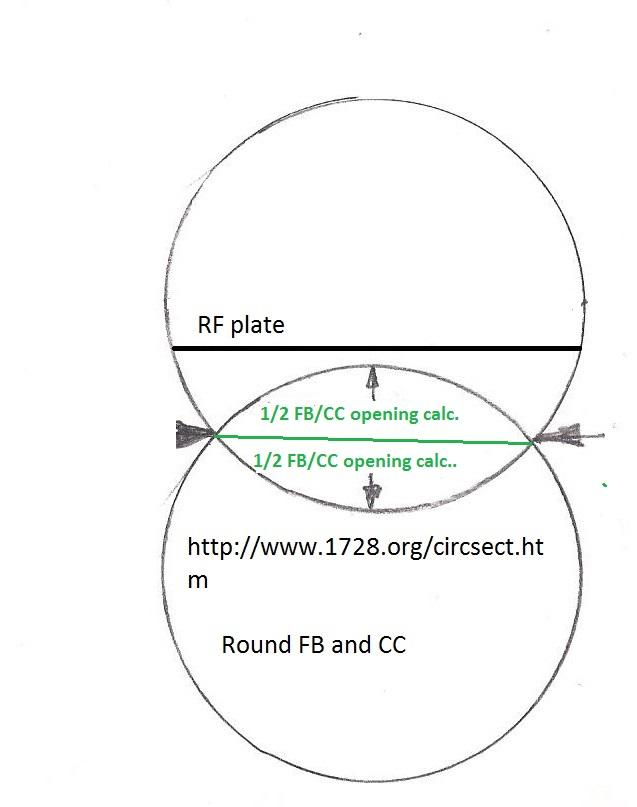

So as for your FB into your CC should look somthing like this.

As for the metal inside your FB, it sounds like that parts covered, so disregard that aspect. As long as the inlets are lower or at fire level.

The green part on Dave's diagram, is where the cut out should be. In my case the FB sits just shy of 7" inside the CC. Hopefully that clears that up.

As for the FB into the cooking chamber, you'll have to line that up as close as possible to save yourself self weld time.

As for the metal inside your FB, it sounds like that parts covered, so disregard that aspect. As long as the inlets are lower or at fire level.

The green part on Dave's diagram, is where the cut out should be. In my case the FB sits just shy of 7" inside the CC. Hopefully that clears that up.

As for the FB into the cooking chamber, you'll have to line that up as close as possible to save yourself self weld time.