Good day all. Just got done making 2 bellies of bacon this weekend. I used the 10% brine method and cured for 13 days. A bit longer than I normally do my cure but circumstances demanded it.

I took a good amount of photos for your enjoyment. I had family over helping yesterday so I got a dearth of photos for slicing and bagging.

I sliced my bacon with a Globe G12 slicer and packed it with a Cabela's vacuum sealer.

Making sure scales are working and calibrated: (10 g test weight)

Pork belly in store package:

Calculation sheet:

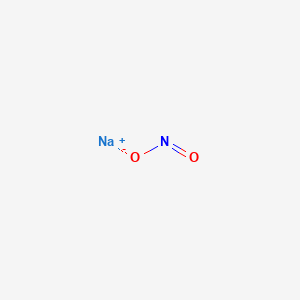

Cure mix:

Measuring Vacuum bag for fit:

Belly in bag ready for cure mix:

Cure added and sealed. Ready for cure in fridge.

Smoked, sliced, and packaged. Brown sugar bacon and molasses bacon.

I took a good amount of photos for your enjoyment. I had family over helping yesterday so I got a dearth of photos for slicing and bagging.

I sliced my bacon with a Globe G12 slicer and packed it with a Cabela's vacuum sealer.

Making sure scales are working and calibrated: (10 g test weight)

Pork belly in store package:

Calculation sheet:

Cure mix:

Measuring Vacuum bag for fit:

Belly in bag ready for cure mix:

Cure added and sealed. Ready for cure in fridge.

Smoked, sliced, and packaged. Brown sugar bacon and molasses bacon.