500 gallon fattie build

- Thread starter Remy Bernabela

- Start date

-

Some of the links on this forum allow SMF, at no cost to you, to earn a small commission when you click through and make a purchase. Let me know if you have any questions about this.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

SmokingMeatForums.com is reader supported and as an Amazon Associate, we may earn commissions from qualifying purchases.

Today was a long day with a lot of interruptions. This thing is drawing a lot of attention over here. The cost of that is that I only managed to finish up the "floting" rails and make 2 grates. It's all 1.5" angle iron 5/32" for the rails and 1/4 for the grates. The stops are 1/4 angle. I can sit on them without it giving into my 178 pounds. I bet it will hold at least 50 more pounds minimum. Tomorrow I'll take the rig to a more private location so I can assemble the 3th grate, weld in all the 1/4" bars in and add the stopping blocks to stop them from sliding out unwanted.

Total surface will be 39 square ft. The warmer box addition will put me on 83 if the calculations stay the same.

And man I love this colour!!! But I made a poll whether to paint it or not and the public wants it painted. I'll go for that because this thing is for business and if people here find it more appealing painted, that's what I'll do.

Should be done and ready for paint and seasoning after if I work on Saturday and Sunday too buffing out welds and final touches.

Total surface will be 39 square ft. The warmer box addition will put me on 83 if the calculations stay the same.

And man I love this colour!!! But I made a poll whether to paint it or not and the public wants it painted. I'll go for that because this thing is for business and if people here find it more appealing painted, that's what I'll do.

Should be done and ready for paint and seasoning after if I work on Saturday and Sunday too buffing out welds and final touches.

Last edited:

She is done! I sanded the inside down with sandpaper to keep the rust dust down. Then I used the sand disk on the grinder and smoothed the inside. I started a small fire to get it hotter (this sun is killing us here) and then blasted the inside with a high pressure. I kept the ball valve closed to see if the rf plate is working like I wanted it to. It's working fine!

During the heating process the temps stayed within 5 degrees F from left to right the whole time and were dead even from 180 and up. Thin blue smoke all the time. I sprayed the inside with Pam already.

Only thing left to do is finish the top 2 grates. The welder will do that for me while I get this baby ready for a bbq competition on the 7th. I also made a elevated rack for the coals. I found two galvanized steps from a stair at the scrapyard and welded the legs that came of the tank to them. I'll burn it out separately before using it inside the smoker. When that's done I'll really fire this baby up and take her to coocking temps and burn the Pam in.

I'll post better pics and post them later today. But the first impressions are VERY VERY good!!! Thank you guys for having this forum which helped me a lot.

During the heating process the temps stayed within 5 degrees F from left to right the whole time and were dead even from 180 and up. Thin blue smoke all the time. I sprayed the inside with Pam already.

Only thing left to do is finish the top 2 grates. The welder will do that for me while I get this baby ready for a bbq competition on the 7th. I also made a elevated rack for the coals. I found two galvanized steps from a stair at the scrapyard and welded the legs that came of the tank to them. I'll burn it out separately before using it inside the smoker. When that's done I'll really fire this baby up and take her to coocking temps and burn the Pam in.

I'll post better pics and post them later today. But the first impressions are VERY VERY good!!! Thank you guys for having this forum which helped me a lot.

One of the grates finished. 1.5"x.25" angle iron, .25" round bars and 1" square tubing.

The door stops. No counterweight needed.

Overlapping doors. One must give room to the other to be lifted up to free the door stop. That's why they don't open evenly.

The baffle plate with 1.5" drain in the middle, 1.5" drop. Inside seasoned.

I also made this dolley on 10" pneumatic tires to move the trailer around. It works GREAT!!!

You can see that the door fix worked out great. When painted you wouldn't know I made that mistake.

It was a pleasure and thanks to this forum for the AMAZING knowledge available which helped me make a good functioning smoker. Still not finished but she has to start filling up my pockets again before I can continue adding stuff to her.

2nd axle

Warmerbox

30 x something ", 3/8" pipe charrgrill

Canvas roof wit bolt on aluminum frame

Sink and storage.

Toolbox.

Updates will be less frequent now but I'll finish this thread for sure.

Specs.

500 gallon 41" x 104" tank

39.5" x 39.5" x 30.5" high firebox

52" x 8" id x .25" thick smokestack

.25" baffle plate

39 sq ft grill surface divided over 3 racks. 7", 6", 3" spacing

16.75' trailer length

15" wheels

3500 lbs single axle

2400 lbs total weight (as is)

The build crew. My aunt's retired husband (welder) and me (everything else including mule).

Thank you guys.

The door stops. No counterweight needed.

Overlapping doors. One must give room to the other to be lifted up to free the door stop. That's why they don't open evenly.

The baffle plate with 1.5" drain in the middle, 1.5" drop. Inside seasoned.

I also made this dolley on 10" pneumatic tires to move the trailer around. It works GREAT!!!

You can see that the door fix worked out great. When painted you wouldn't know I made that mistake.

It was a pleasure and thanks to this forum for the AMAZING knowledge available which helped me make a good functioning smoker. Still not finished but she has to start filling up my pockets again before I can continue adding stuff to her.

2nd axle

Warmerbox

30 x something ", 3/8" pipe charrgrill

Canvas roof wit bolt on aluminum frame

Sink and storage.

Toolbox.

Updates will be less frequent now but I'll finish this thread for sure.

Specs.

500 gallon 41" x 104" tank

39.5" x 39.5" x 30.5" high firebox

52" x 8" id x .25" thick smokestack

.25" baffle plate

39 sq ft grill surface divided over 3 racks. 7", 6", 3" spacing

16.75' trailer length

15" wheels

3500 lbs single axle

2400 lbs total weight (as is)

The build crew. My aunt's retired husband (welder) and me (everything else including mule).

Thank you guys.

Attachments

Last edited:

darkshadow

Fire Starter

That's awesome, will be stunning when you've got the complete set up finished. Sounds like allnyour missing is a spot to hang a hammock.

After about 10 hours of sleep the last 3 days and nights finishing off details and final bits and pieces, 2 empty test runs and then seasoning, off we went to her first event. The wholesale company sponsored 17 picnics and 15 butts for me to smoke and donate them for selling to the Curaçao Culinary Team to gather funds to be able to represent the island internationally.

The day went very fast! I took a buddy of mine (he looks like Franklin) who loves bbq and he was totally blasted away by the fact he got the chance to operate the smoker and work beside me. So our day started at 8 in the morning. And ended around 10 at night. The culture is totally different than yours and my appearance with this beast was a categorie of it's own.

The smoker itself

I can not emphasize how good this beast works and how easy it is to operate by using just fire size and the door on the firebox.

I start if off with 5 logs size of a fist and when they catch fire I throw the bigger pieces on. After that its 1 log per hour as she retains heat like a champ giving me more than an hour to play with.

The 52" tall 8" wide chimney pulls excelent without damper an all those stuffs. Firebox side runs 6 degrees F hotter but it worked out fine with different meat sizes. Smoke was not even thin blue. It was just invicible!!!

Since I made a fire basket using the legs of the tank, I had only white dusty powder at the end of each test.

The pyramid rf plate is the best thing I did on this build! The day after I only had to wipe it down and steelbrush the grates.

I'm not going to change a thing on it untill I add the warmerbox to it. Next thing to do is fabricate the direct grill out of a 30" pipe I have. 3/8" thick. The top will be made of 1/4" to save weight. I got 1000 lbs yet on this single axle.

Here I'll leave you with a few pics I got from visitors.

Upcoming sunday it's ribs sunday. Build Babybacks and half chickens will go on!

Ps. That colour is the final product! My own rub.

The day went very fast! I took a buddy of mine (he looks like Franklin) who loves bbq and he was totally blasted away by the fact he got the chance to operate the smoker and work beside me. So our day started at 8 in the morning. And ended around 10 at night. The culture is totally different than yours and my appearance with this beast was a categorie of it's own.

The smoker itself

I can not emphasize how good this beast works and how easy it is to operate by using just fire size and the door on the firebox.

I start if off with 5 logs size of a fist and when they catch fire I throw the bigger pieces on. After that its 1 log per hour as she retains heat like a champ giving me more than an hour to play with.

The 52" tall 8" wide chimney pulls excelent without damper an all those stuffs. Firebox side runs 6 degrees F hotter but it worked out fine with different meat sizes. Smoke was not even thin blue. It was just invicible!!!

Since I made a fire basket using the legs of the tank, I had only white dusty powder at the end of each test.

The pyramid rf plate is the best thing I did on this build! The day after I only had to wipe it down and steelbrush the grates.

I'm not going to change a thing on it untill I add the warmerbox to it. Next thing to do is fabricate the direct grill out of a 30" pipe I have. 3/8" thick. The top will be made of 1/4" to save weight. I got 1000 lbs yet on this single axle.

Here I'll leave you with a few pics I got from visitors.

Upcoming sunday it's ribs sunday. Build Babybacks and half chickens will go on!

Ps. That colour is the final product! My own rub.

Last edited:

Got working on a 42x30" santa maria grill/little smoker combo. I had a costumer who just wanted me to direct grill, so I improvised as you can see in the pic below. I used 2 grates of my smaller smoker and supported them in the middle with a 12" piece of 4x4" pipe I have.

Before I got the tank, the idea was to use a 30", 3/8" pipe I bought. Then came the tank and my plans shifted. As the pipe was already cut, I had to use that piece of it no matter what. So I did.

I made a frame from 1.5" by 1/4" thick angle iron to even out the tolerances from cutting the pipe and to function as 2 legs to sit on the trailer. It sits over the half pipe like a lid on a tupperware. It also gives me a straight and flat surface for the lid to sit on for a good seal.

The height of the grill is also the height of the stainless prep table all around the trailer.

I made the coal rack with some 5/8" rod leftover lengths I had. And made the grate from 1/4" rods.

A front door for cleaning out was added. A damper will be made later. Trying to keep some nice lines throughout the build. Keeping it round where I can.

Got to get me a 3/16" sheet to make a lightweight top and cut out a door in it and flange it. The santa maria mechanism will be on the inside, but covered up and protected against grease and stuff. An 6" exhaust pipe will be added later so the grill can operate as an offset smoker for roasting chickens or crisping pork at higher temperatures.

I also started on the theme of my company by painting the trailer, hinges, flanges and some small stuff black. My logo will be an artwork from a local artist. Gonna look like it's burning off the smoker.

Also made a damper. Wasn't t really needed. Or at least didn't feel like something was wrong and I needed it. This rig operates very good!!! But the damper did improved the wood consumption a bit and also even the temps vertically to dead even!!! Haven't cook on it with damper yet. But I like the high airflow concept. Didn't have to wrap ribs up on this smoker.

And look how I placed the removable sign. Weld the top hinge in place and hang the sign. Then give the lower hinge a bit of space. That makes it easy to hang the sign by your own even in strong winds. You align the top and then the lower instead of trying to align both at the same time.

Overall looks untill now. A busy weekend ahead and after that one more week untill I come to the States on a short learning vacation. Will be visiting Texas on invitation of the U.S. Meat Export Federation. Hopefully I can start using their products more often and better the quality of my work. Also visiting Salt lick, Franklin etc.

Next thing will be the theme matched fenders, finish the santa maria and adding the stainless table on the smoker side. But first the U.S.!!!!

Before I got the tank, the idea was to use a 30", 3/8" pipe I bought. Then came the tank and my plans shifted. As the pipe was already cut, I had to use that piece of it no matter what. So I did.

I made a frame from 1.5" by 1/4" thick angle iron to even out the tolerances from cutting the pipe and to function as 2 legs to sit on the trailer. It sits over the half pipe like a lid on a tupperware. It also gives me a straight and flat surface for the lid to sit on for a good seal.

The height of the grill is also the height of the stainless prep table all around the trailer.

I made the coal rack with some 5/8" rod leftover lengths I had. And made the grate from 1/4" rods.

A front door for cleaning out was added. A damper will be made later. Trying to keep some nice lines throughout the build. Keeping it round where I can.

Got to get me a 3/16" sheet to make a lightweight top and cut out a door in it and flange it. The santa maria mechanism will be on the inside, but covered up and protected against grease and stuff. An 6" exhaust pipe will be added later so the grill can operate as an offset smoker for roasting chickens or crisping pork at higher temperatures.

I also started on the theme of my company by painting the trailer, hinges, flanges and some small stuff black. My logo will be an artwork from a local artist. Gonna look like it's burning off the smoker.

Also made a damper. Wasn't t really needed. Or at least didn't feel like something was wrong and I needed it. This rig operates very good!!! But the damper did improved the wood consumption a bit and also even the temps vertically to dead even!!! Haven't cook on it with damper yet. But I like the high airflow concept. Didn't have to wrap ribs up on this smoker.

And look how I placed the removable sign. Weld the top hinge in place and hang the sign. Then give the lower hinge a bit of space. That makes it easy to hang the sign by your own even in strong winds. You align the top and then the lower instead of trying to align both at the same time.

Overall looks untill now. A busy weekend ahead and after that one more week untill I come to the States on a short learning vacation. Will be visiting Texas on invitation of the U.S. Meat Export Federation. Hopefully I can start using their products more often and better the quality of my work. Also visiting Salt lick, Franklin etc.

Next thing will be the theme matched fenders, finish the santa maria and adding the stainless table on the smoker side. But first the U.S.!!!!

Last edited:

Never returned to this site since last post. It was just CRAZY owning a smoker like this over here on the island. Have been working for months without a break. But in between I learned myself how to weld and just kept on building little by little while I can. But already outgrowing this rig and it's not even finished.

I placed a second axle for stability and because I was about 300 lbs to heavy for a single 3500 lbs. But that shifted too much weight to the back and it wasn't safe on the road. I made some matching themed fenders as well from scratch. I only had a hammer to curve the strips until they matched.

And work upon work and more work. At my first public tasting event I was the second vendor with most sales. These smokers can produce a lot!!! :P

Some more work I did...

And a few culinary private event for small groups of people...

And to be able to save wood for smaller jobs i made this 170 gallon offset from the piece of 30" pipe. That should've been what the above is today. Glad I didn't do it. It's just too small. For the firebox I bought a 24" piece of pipe. Whole project costed me 650 US bucks.

The first items that came from it.

But still I had to address the 500 gallon trailer issue. Build a new trailer of modify the current one with limited tools and that hot sun. So I just stretched the trailer by 5 ft. 21 ft is her total length now and she pull much better. Still need more tongue weight but that will came in the form of a bigger slide out santa maria grill, sink etc. That opens the door to add a warmer box and insulate the firebox which adds more weight behind the axles.

As she is today....

I placed a second axle for stability and because I was about 300 lbs to heavy for a single 3500 lbs. But that shifted too much weight to the back and it wasn't safe on the road. I made some matching themed fenders as well from scratch. I only had a hammer to curve the strips until they matched.

And work upon work and more work. At my first public tasting event I was the second vendor with most sales. These smokers can produce a lot!!! :P

Some more work I did...

And a few culinary private event for small groups of people...

And to be able to save wood for smaller jobs i made this 170 gallon offset from the piece of 30" pipe. That should've been what the above is today. Glad I didn't do it. It's just too small. For the firebox I bought a 24" piece of pipe. Whole project costed me 650 US bucks.

The first items that came from it.

But still I had to address the 500 gallon trailer issue. Build a new trailer of modify the current one with limited tools and that hot sun. So I just stretched the trailer by 5 ft. 21 ft is her total length now and she pull much better. Still need more tongue weight but that will came in the form of a bigger slide out santa maria grill, sink etc. That opens the door to add a warmer box and insulate the firebox which adds more weight behind the axles.

As she is today....

Last edited:

Wow glad you have been busy with the new pit. I have also been real busy and am not on this forum much. Been hard at work making new pits. Heres some 500 gallon bbq pits I building atm.

Great looking food !!! Thanks for the post.

Great looking food !!! Thanks for the post.

Attachments

Last edited:

Yes man. It's crazy over here. I grew so fast in the last 3 months. I worked non stop from December 15 till January 6th with 3 hours sleep average. I took a few weeks off until this Saturday. Also working on a restaurant now and gathering parts for a 1000 gallon Moberg style. Build it myself is cheaper and I can't wait a year to receive it. But I'll keep doing events and catering as a division of the restaurant. So I will complete this rig and use it mainly for events.

Let me check out your 500 builds.

Let me check out your 500 builds.

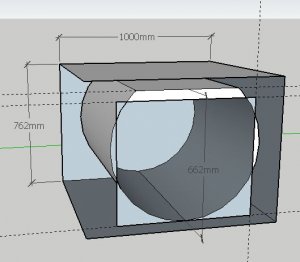

I want to improve the wood usage of my smoker by insulating the firebox. I have a piece of 30" 3/8" pipe I can use. However, the firebox measures 30" (762mm) high, 39,5" (1000 mm) wide and long. The pipe will not leave room above and underneath for insulation. So as you can see in the drawing, I want to take off 4" from the height by making the top of the pipe flat.

The problem is that the volume will be reduced from 121% uninsulated as it is now to about 65% insulated. Will it work? I don't mind playing with the smokestack to create more draft. Thinking like a 1000 gallon smoker principle.

The problem is that the volume will be reduced from 121% uninsulated as it is now to about 65% insulated. Will it work? I don't mind playing with the smokestack to create more draft. Thinking like a 1000 gallon smoker principle.

Attachments

Does your firebox run really hot ???? If so, you may have an issue with air flow through the smoker...

Check your smokers dimensions with this tutorial and see if all is OK or some modifications are in order...

One thing you can try is adding air inlets across from the FireBox/CookChamber opening... What that does is 2 things...

Increases the air flow through the smoker to even out temps... Then it moves excess heat from the FireBox to the CookChamber...

When all that comes into balance, fuel consumption is reduced to a minimum level...

Smoker Calculator

I would insulate the outside so as to not screw up the FB.....

Check your smokers dimensions with this tutorial and see if all is OK or some modifications are in order...

One thing you can try is adding air inlets across from the FireBox/CookChamber opening... What that does is 2 things...

Increases the air flow through the smoker to even out temps... Then it moves excess heat from the FireBox to the CookChamber...

When all that comes into balance, fuel consumption is reduced to a minimum level...

Smoker Calculator

I would insulate the outside so as to not screw up the FB.....

No it doesn't run REALLY hot. I use the entire door as air inlet. No additional inlets here. The box is 5/8" thick. I usually run the smoker at 250F and the outside of the box is also 250-ish. Seems ok to me.

I can only insulate from the inside. The box is now 121% and is welded to the trailer. Working on the inside is much easier for me.

She's doing great!!! But I almost ran out of wood twice since I had her and I'm starting a restaurant within a few months. So consumption becomes an issue and if possible I'll try to do something about it. So it's not because the cooker is not performing right. I can take her up to 400F with smaller pieces of wood. She also runs dead even when heated up. Check how she runs.

I can only insulate from the inside. The box is now 121% and is welded to the trailer. Working on the inside is much easier for me.

She's doing great!!! But I almost ran out of wood twice since I had her and I'm starting a restaurant within a few months. So consumption becomes an issue and if possible I'll try to do something about it. So it's not because the cooker is not performing right. I can take her up to 400F with smaller pieces of wood. She also runs dead even when heated up. Check how she runs.

It's been a while. The business is growing SO SO fast!!! I started with no money and a lot of time. Now I don't have time to even finish her as I wish. I had to put weight back in front of the axles after stretching the trailer. That would requite less weight further up front. So I had a chance to make a santa maria grill from leftovers I had from this project.

A wooden deck is also added so I can transport all my catering equipment on the trailer itself. Now I don't have to unload everything and load them back up in the pick up truck.

That gave me the possibility to add the much needed warmer box.

- insulated between firebox ceiling and warmer bottom

- 5 racks (80% extra capacity over the tank area)

- dampers from firebox to warmer and tank to warmer

- extra rack for hanging sausages

- charcoal maze basket insert for grilling

And the best upgrade yet too place last week. I upgraded the firebox (which Feldons calculated WAAAAY to big), and insulated it. I took 3/8 x 30" half pipe from my other smoker build I had over and enclosed it in the firebox with insulation wrapped around it.Now she burns 1 log every 1.5 hours @ 225F and 2 logs almost 2.5 hours @ 300F, pulling through the warmer box and big stack closed.

If you have a fire you might as well put some meat on it....

So what's left on this project?

- Sink

- Wood storage

- Finish the equipment storage

- Lights for working during the nights

But I'm moving the catering business away from home. It's getting too big now. And business is still growing fast. I'm starting a restaurant and a truck together with the catering. So before I finish this project I will have to start on this one first in a new thread. Meet Eclipse....

A wooden deck is also added so I can transport all my catering equipment on the trailer itself. Now I don't have to unload everything and load them back up in the pick up truck.

That gave me the possibility to add the much needed warmer box.

- insulated between firebox ceiling and warmer bottom

- 5 racks (80% extra capacity over the tank area)

- dampers from firebox to warmer and tank to warmer

- extra rack for hanging sausages

- charcoal maze basket insert for grilling

And the best upgrade yet too place last week. I upgraded the firebox (which Feldons calculated WAAAAY to big), and insulated it. I took 3/8 x 30" half pipe from my other smoker build I had over and enclosed it in the firebox with insulation wrapped around it.Now she burns 1 log every 1.5 hours @ 225F and 2 logs almost 2.5 hours @ 300F, pulling through the warmer box and big stack closed.

If you have a fire you might as well put some meat on it....

So what's left on this project?

- Sink

- Wood storage

- Finish the equipment storage

- Lights for working during the nights

But I'm moving the catering business away from home. It's getting too big now. And business is still growing fast. I'm starting a restaurant and a truck together with the catering. So before I finish this project I will have to start on this one first in a new thread. Meet Eclipse....

WELL.... I'm back at it. We went in a second lockdown. So I transported my welding equipment on my bike to the shop where I could build my new trailer for the smoker. I know now what capacity I need and sun/rain etc has always been an issue with no roof above our head when we are catering. The old trailer has no tongue weight due to the upgrades I did (warmer box and insulating the firebox.

So, I sold the santa maria grill to one of my young helping hands and the lockdown gave me the much needed time to fully focus on the build.

- New roofed trailer made with better steel.

- From 7k to 10k axles with new tires and the whole package.

- Serving window.

- New direct grill/pig cooker

- I hope you see it!!!

I leave you with some pics as I did not take many.

So, I sold the santa maria grill to one of my young helping hands and the lockdown gave me the much needed time to fully focus on the build.

- New roofed trailer made with better steel.

- From 7k to 10k axles with new tires and the whole package.

- Serving window.

- New direct grill/pig cooker

- I hope you see it!!!

I leave you with some pics as I did not take many.

SmokingMeatForums.com is reader supported and as an Amazon Associate, we may earn commissions from qualifying purchases.

Similar threads

- Replies

- 6

- Views

- 4K

- Replies

- 3

- Views

- 1K

- Replies

- 4

- Views

- 1K

- Replies

- 1

- Views

- 354

Hot Threads

-

Is anyone here in the automotive or truck sales business?

- Started by forktender

- Replies: 39

- General Discussion

-

Featured Prime Boneless Striploin Steaks on the Q

- Started by DRKsmoking

- Replies: 21

- Beef

-

Bucket list Smoker - Humphrey's Pint

- Started by dward51

- Replies: 20

- General Discussion

-

Your Favorite Way to Use Leftover Smoked Pork Ribs

- Started by Jim_C

- Replies: 19

- General Discussion