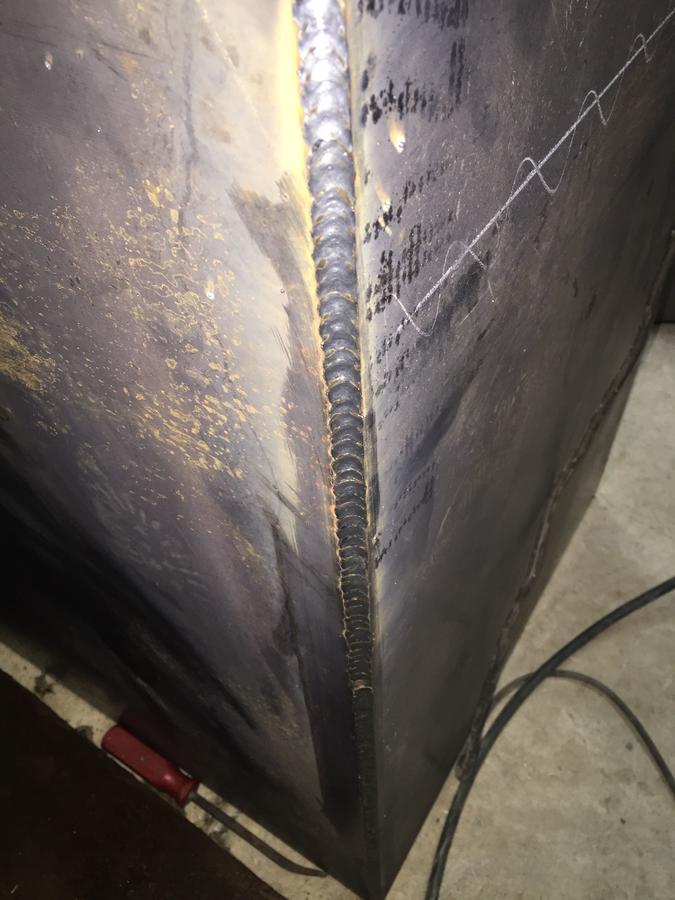

Looks good.

You welding is slick, so don't bother wasting wire/gas on the inside.

If you have not welded it yet just do the outside in downhand. Roll it around and weld downwards. It will give you a better looking weld nd plenty strong enough.

You welding is slick, so don't bother wasting wire/gas on the inside.

If you have not welded it yet just do the outside in downhand. Roll it around and weld downwards. It will give you a better looking weld nd plenty strong enough.