I am in the planning stages of a smoker build using 2 - 250 gallon propane tanks I am hoping to acquire next week.

After doing a few hours of reading, I have come up with a few questions that I hope are worthy.

Conventional flow offset VS reverse flow offset

Is there an advantage to putting in the extra time and materials to build a reverse flow unit? It seems the me that the physics of the cooker remain the same with a hot spot near the fire box getting cooler farther from the fire.

Stack combustion control VS firebox intake control only

I have seen most offset smoker designs use a free flow stack output design. This means that combustion is controlled entirely from the firebox air intake.

Is there an advantage in tuning the pipe for a specific flow?

Stack intake position

I know there is a great amount of debate over this issue so I am going to state my current understanding of this issue.

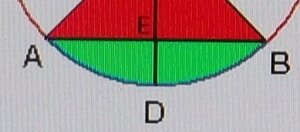

It would seem to me that the opening to the smoke stack should be no higher than 50% of the cook chamber height. This would help the area of the smoker farthest away from the fire box to maintain a bit more heat. Airflow over the food may be reduced very close to the stack but that may not be a big issue as air flow will still be significant.

Welding equipment preference

I have been trying to get information on what kind of welder would be best for a newbie to use on a project like this. The 2 answers I have gotten are either a MIG or a stick welder. Any opinions on this?

Current Plans

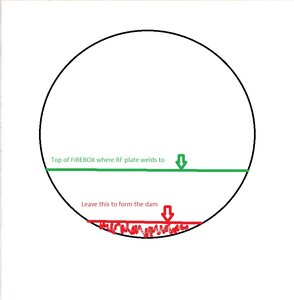

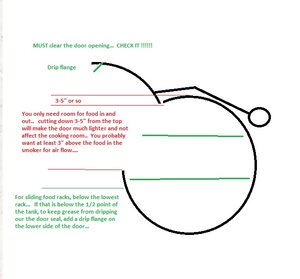

If anyone is interested, I have attached my initial round of calculations for the unit. Drawing is just a rough concept right now. Shout out to daveomak

and

daveomak

and

gary s

for the wealth of information on building these units.

gary s

for the wealth of information on building these units.

Thanks,

JC

After doing a few hours of reading, I have come up with a few questions that I hope are worthy.

Conventional flow offset VS reverse flow offset

Is there an advantage to putting in the extra time and materials to build a reverse flow unit? It seems the me that the physics of the cooker remain the same with a hot spot near the fire box getting cooler farther from the fire.

Stack combustion control VS firebox intake control only

I have seen most offset smoker designs use a free flow stack output design. This means that combustion is controlled entirely from the firebox air intake.

Is there an advantage in tuning the pipe for a specific flow?

Stack intake position

I know there is a great amount of debate over this issue so I am going to state my current understanding of this issue.

It would seem to me that the opening to the smoke stack should be no higher than 50% of the cook chamber height. This would help the area of the smoker farthest away from the fire box to maintain a bit more heat. Airflow over the food may be reduced very close to the stack but that may not be a big issue as air flow will still be significant.

Welding equipment preference

I have been trying to get information on what kind of welder would be best for a newbie to use on a project like this. The 2 answers I have gotten are either a MIG or a stick welder. Any opinions on this?

Current Plans

If anyone is interested, I have attached my initial round of calculations for the unit. Drawing is just a rough concept right now. Shout out to

Thanks,

JC