They have an 11 hectare property full of propane tanks, there are some monster tanks. Probably about 5-10,000 tanks

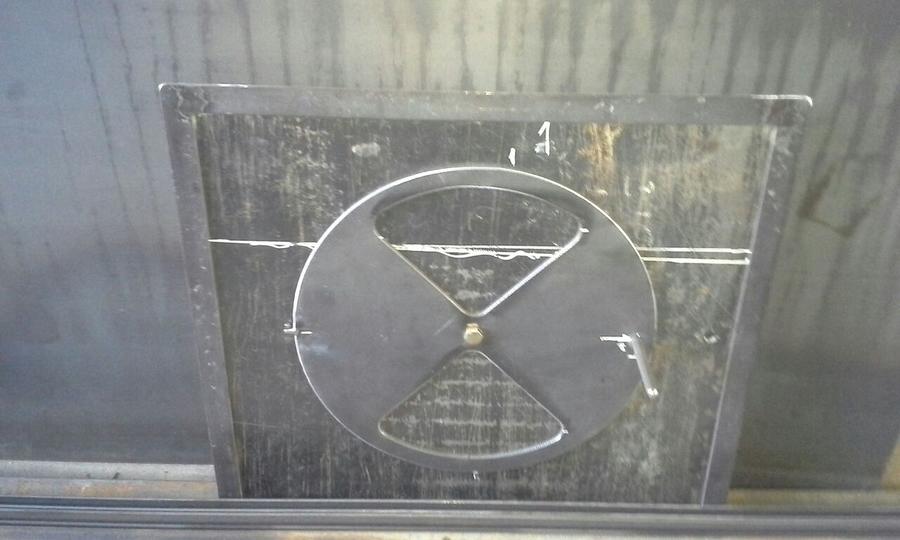

First tank ready for the 9" grinder and plasma cutter.

I purchased 6 tanks. 4 1000 liter (262 gallon) and 2 2000 liter.

They have been sandblasted but left outside, so a quick lick with the wire wheel on the grinder is good enough.

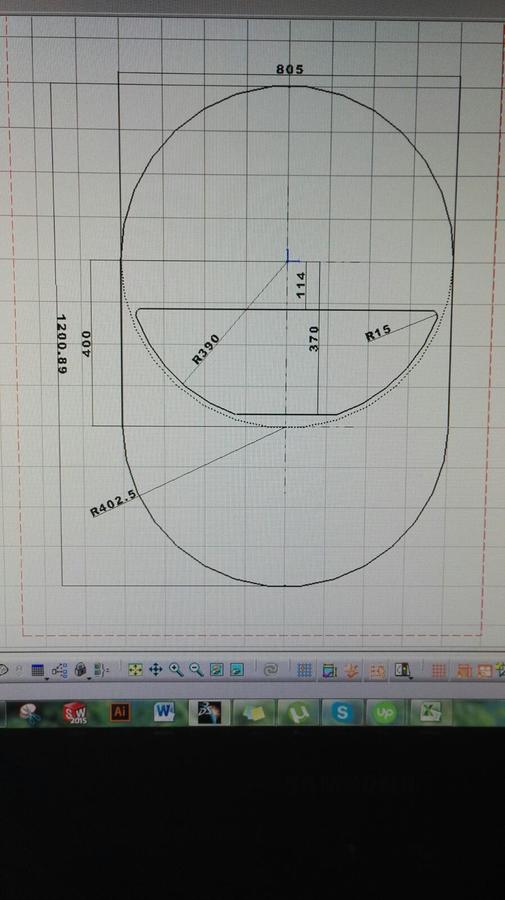

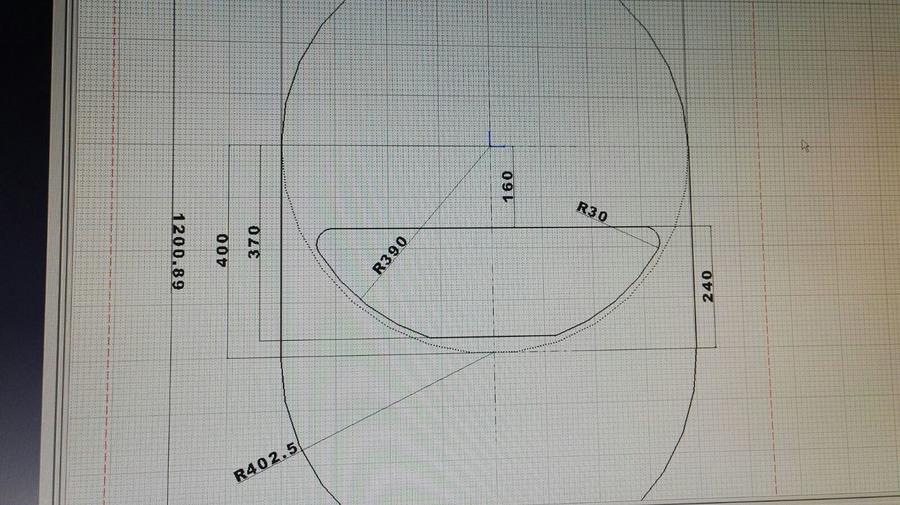

I will cut the head off one end to make room for a parrilla.

Using Dave's numbers i came up with 262 gallon tank minus 1 head is 248 gallons. 57,288 cubic inches This build should go pretty fast so stay tuned.

First tank ready for the 9" grinder and plasma cutter.

I purchased 6 tanks. 4 1000 liter (262 gallon) and 2 2000 liter.

They have been sandblasted but left outside, so a quick lick with the wire wheel on the grinder is good enough.

I will cut the head off one end to make room for a parrilla.

Using Dave's numbers i came up with 262 gallon tank minus 1 head is 248 gallons. 57,288 cubic inches This build should go pretty fast so stay tuned.