- Mar 28, 2020

- 16

- 9

I'm looking to build a smokehouse similar to this one. I'm shooting for interior dimensions of 36" wide, 30" deep, and 4-5' high. The walls would have 1.5" foam board insulation with concrete board on the inside sides and bottom (30" high) and plywood at the top. Floor and ceiling would also be insulated.

I'm in Minnesota and smoke year round. I want to be able to do both hot and cold smoking. I do bacon, sausage, snack sticks, but also like to do hot smoking as well. For cold smoking I'll use an AMPS for smoke source. For heat, I have questions.

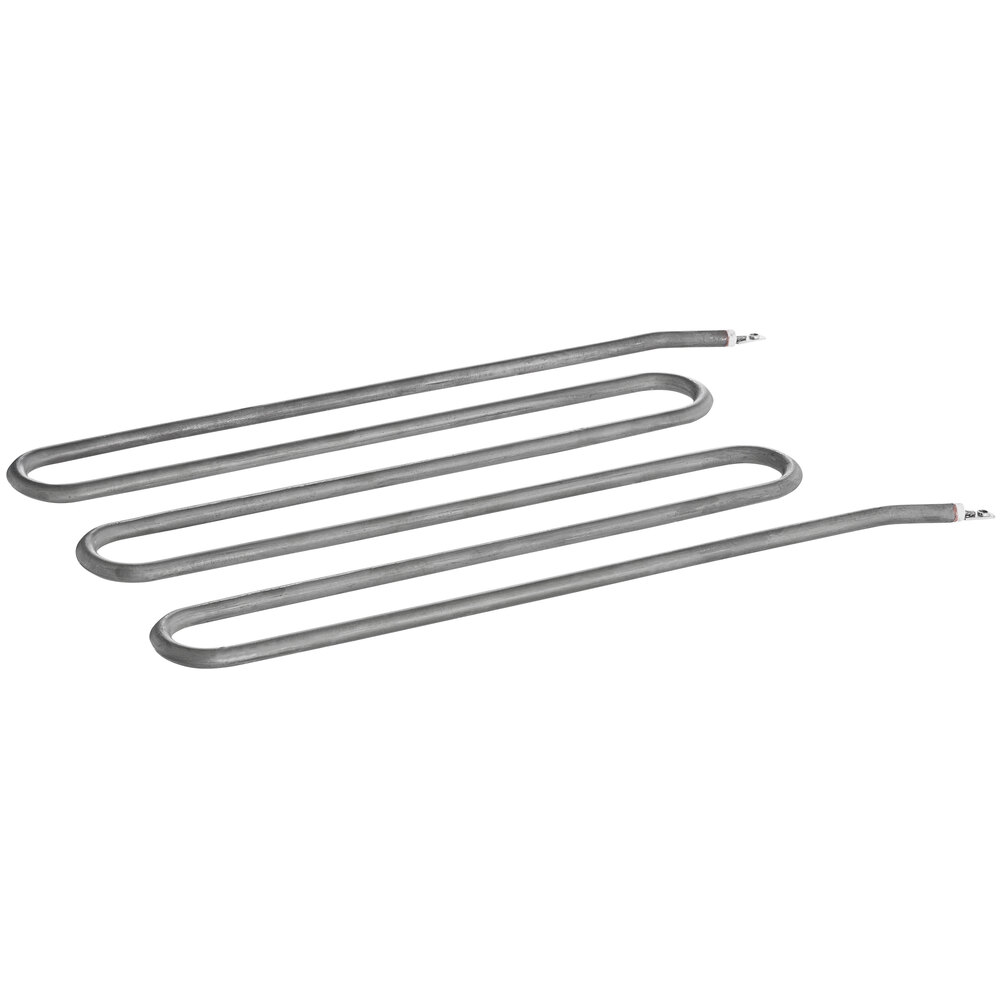

I'm looking for input/ideas on heat sources. I'm coming from a modified Bradley with a PID. I really like the temp control of the PID. Do you think 2 900W heating elements would be enough to heat it? 2 Elements would draw about 15amps. The smokehouse would be about 50-60 feet from the nearest outlet. Is that too much for a good extension cord?

I could use a propane burner, definitely easier. What are people using for propane temp control. I want to be able to set a temp and walk away for a couple of hours. I'll have remote thermometers, so I can monitor it.

Thanks in advance for you suggestions!

I'm in Minnesota and smoke year round. I want to be able to do both hot and cold smoking. I do bacon, sausage, snack sticks, but also like to do hot smoking as well. For cold smoking I'll use an AMPS for smoke source. For heat, I have questions.

I'm looking for input/ideas on heat sources. I'm coming from a modified Bradley with a PID. I really like the temp control of the PID. Do you think 2 900W heating elements would be enough to heat it? 2 Elements would draw about 15amps. The smokehouse would be about 50-60 feet from the nearest outlet. Is that too much for a good extension cord?

I could use a propane burner, definitely easier. What are people using for propane temp control. I want to be able to set a temp and walk away for a couple of hours. I'll have remote thermometers, so I can monitor it.

Thanks in advance for you suggestions!