I did not see this, but how many watts are your 2 heating elements (how many each)? That is the load that determines what amperage will actually be used and what wire gauge is needed along with what fusing/breaker for safety.

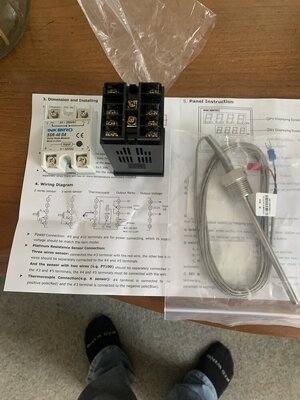

Also I did not see a heat sink for the SSR in your photo. Do you have that? It *WILL* be necessary as the SSR will get hot in use. Again, heat sink size depends on the load amperage (wattage of the 2 heating elements).

And there are a number of other parts your Electrician (family member) will need to complete the wiring. Things like connectors, buss strips to connect the power cord to and break out the 2 circuits to power the elements, PID & SSR, etc... plus connectors are specific to wire size. Just because it came with a 40 amp SSR does not mean you will need 40 amps of 240v power. It is probably way less for the actual elements unless they are huge (huge in power consumption, like 3,000 watts each).