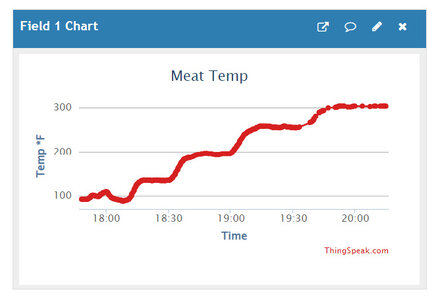

I just couldn’t resist getting the digital version of my MES30 smoker. It’s used but in good condition and everything works. I gave it a quick wipe down inside with the vinegar wash, wash the outside and I’m soaking the racks and rack holders in the sink. I’m putting it through its paces now had it up to 320°, I sure love these insulated versions, it was up to 200° in less than five minutes amazing. I’m tracking the temperature now with my external probe and giving it some smoke to re-season the inside walls. This is the version with 6 rack holders, exactly what I was looking for.

Ultimately, I probably will put a P ID on it, it’s only trouble right now, of course is it over shoots, but for most scenarios that’s not a problem. I have wild thoughts of stacking this with my analogue MES30 for dual chamber smoking. I have a few options to consider.

Just thought I’d let you know to make one more space available in the asylum.

Cheers

Ultimately, I probably will put a P ID on it, it’s only trouble right now, of course is it over shoots, but for most scenarios that’s not a problem. I have wild thoughts of stacking this with my analogue MES30 for dual chamber smoking. I have a few options to consider.

Just thought I’d let you know to make one more space available in the asylum.

Cheers

Last edited: