Thanks for your response. the more I read, the more I understand there are issues with the MES controller. Excuse my ignorance, what is a PID controller? Any chance you could show me a pic of those 4 wires and how you hook them up?

With regards to cranking it up to 275, when I get to 250, as soon as I go to 251, the controller goes back to 100!! Won't let me go past 250.

I don't know where the temp probe is in the MES but if I found it, would giving it a clean make a difference? Just thinking out loud here.

Finally, is it the probe itself or the digital controller on top of the MES that is the issue?

A PID controller is just a device similar to the controller that is on top of your MES. You will enter in the cooking temperature that you want. It has a temp probe that you drop down the vent of your MES and clip to the bottom center section of your lowest smoker rack so it can sense your smoker temp. Finally, it will take power from your wall out let and feed that power on/off to your rewired MES so the MES heats up to the set temp you put into the PID controller and then controller will then feed/cut power as needed to hit and hold the temperature spot on.

PID stands for Proportional, Integral, Derivative which are 3 setting values you enter/change so the controller can properly and precisely control the heat in your smoker :D

Here is a pick of the 4 wires:

Notice wires 3 & 4 are braided wires vs smooth insulation. Your smoker may have different colored wires (maroon, red & blue, etc.) but what remains the same is you will have 2 braided and then 1 white smooth and 1 black smooth. You always connect smooth to braided and the order doesn't really matter in these devices. It only matters that you connect the smooth in the pic to the braided in the pic.

Here is a detailed write up on rewiring and doing anything/everything you need to use a PID controller with a rewired MES :D

Lately I've seen a number of posts about guys wanting to rewire their MES. I had wanted to post a quick and simple guide for those out there that are curious or those that simply need to rewire but need a little assistance. Well here goes. Disclaimer: When messing with electrical equipment...

www.smokingmeatforums.com

With the last info you provided I think you may have a different and very common problem. It sounds to me like your high temp switch is failing you.

Why do I say this?

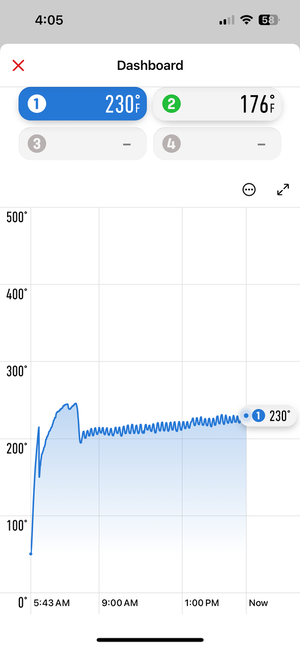

Well if yo set your smoker to 250F or basically any temp and the smoker heats up to that temp for a little bit then drops drastically for no reason, THEN heats back up again, and repeats the cycle... this is classic behavior indicating your high temp switch is sensing a high temp (305F+) and is cutting power to the heating element.

How could it be sensing this temp if not even over 250F smoker temp??

The switch itself is a cheap mostly plastic part.

Masterbuilt also uses the cheapest most horrible wire connectors on their MES wires and they rust and corrode away criminally fast.

If you have rust or corrosion at the connectors, they will cause resistance at the switch, which leads to heat build up (electricity + resistance = heat, kind of how the heating element works).

The switch itself is being super heated in this situation, not your smoker. The switch reads it's overheated temp and cuts the power off to the heating element.

Additionally, this overheating gets worse and faster AND the cheap plastic switch will begin to melt down and eventually just fail and you will get no power to your heating element.

So, I think your problem is pretty much that switch which does not require a full rewire and PID. Just fixing the switch problem.

The solution is pretty simple. You access that switch and see if you just need to replace connectors but realistically that switch is super cheap and if having these problems is likely on it's last legs so could probably due with being replaced as well.

Additional problems with this... most MES units do NOT have a panel to easily access this switch and you likely have to cut a panel. This sucks that you have to do it, but it's a good thing since the switch is a common failure point.

Here is anther detailed write up on how to find the safety high temp switch and the replacement parts, etc.:

The MES safety rollout limit switch is a common point of failure so I am making this post to have pictures of it that I can easily find instead of digging up new ones everytime we help someone with this issue. Also adding tags so it's easy to search in SMF and hopefully via Google as well...

www.smokingmeatforums.com

(Definitely check out that post to see all the pictures of how to locate your safety switch)

For ease, here are some ceramic switches that are 180C/356F temp limits for a decent price and fast shipping (GET THESE EXACT ONES, because others that look similar might be the 2 piece design which won't work, instead of this 1 piece design). Ceramic means no easy melting down since the aren't plastic. Also 356F limit is about 51F degrees higher than the stock safety switch BUT if you ever decide to rewire and go the PID route, you can now do 2-4 hours smokes at 325F degrees to get that pesky chicken/turkey skin to not come out rubbery. WARNING: MES insulation is not rated to be running over 325F for very long, so all other smokes would be a max temp of 275F smoker temp. It's just nice to have the option :D

https://www.amazon.com/Aopin-Therma...-20-spons&sp_csd=d2lkZ2V0TmFtZT1zcF9idGY&th=1

Here's some good quality hi-temp wire connectors that fit the wires and the tabs for the MES. The stock MES connectors fail all the time and these get the job done without corroding away on you like the stock ones do.

https://www.amazon.com/Supco-T1111-...1720386019&sprefix=supco+t1111,aps,144&sr=8-1

Last option dealing with the safety switch issue, I mention this part last.

If you use lots of thermometers in your smoker all the time and the thermometer can have high temp limit alarms, you have another simpler option, but WARNING!!!! This options means you are taking responsibility for removing the safety switch mechanism completely, so know that this is all on you and no one else :D

This option is to simply go to the high temp safety switch, but the wire ends off it and then wire not those wire ends together.

This means you have eliminated the switch and corroding connectors completely.

This is a really good step to troubleshoot that your safety switch is the culprit and failing on you when you don't see any visible signs of it burning or melting down or the connectors screwing up there.

You do this and then run the smoker and see if it behaves.

If the smoker behaves you then determine if want to replace the safety switch or run without one. Up to you.

Conclusion

I think you start troubleshooting with the safety switch. This means you are likely cutting a panel there following that post I included. Again, having this panel is actually a good thing where you do it and cry once and then benefit from having it from here on out hahaha.

Do the troubleshooting of wiring around your switch but WARNING the switch is now gone from the mix but you will know if it is the problem.

See if what you want to do with your smoker if the switch is the problem (I'd almost bet money it is based on the behavior you mentioned).

One last thought. If you now have a panel and sort out your switch problem. You could still decide you want to do the simple rewire and go with a PID controller.

Doing this means your MES becomes super performing beast with tight temp control AND.... you will basically be able to keep it running through anything short of it being hit by lightning if you replace the heating element connectors with good ones. Your MES will have to physically fall apart or walk off on you for it to be out of commission. If the element ever dies (not that common) it's a cheap and readily available replacement part. I can't overstate how long you can make this thing go in this case :D

I threw a ton at you here. Let us know if you have any questions :D