- Sep 16, 2012

- 15

- 10

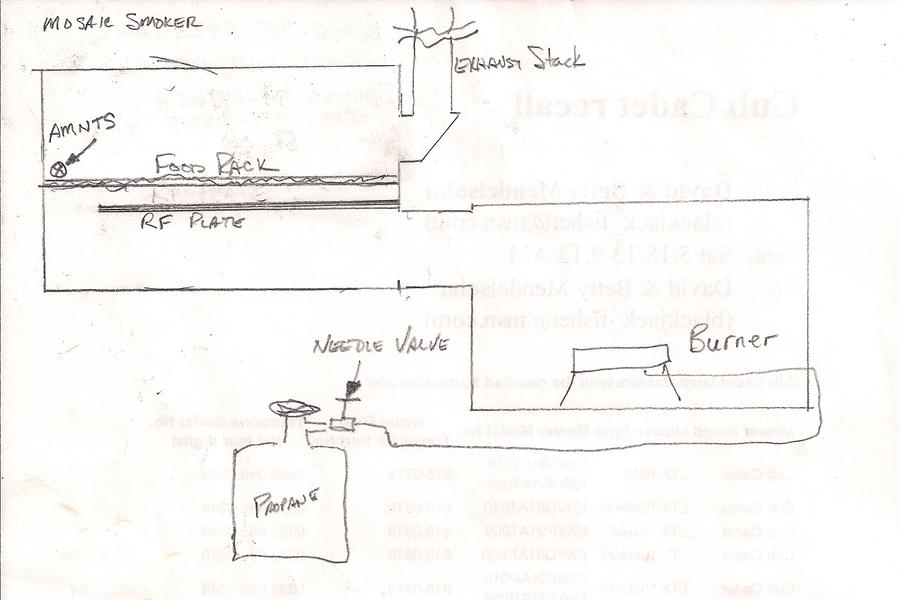

My son and I just bought a couple 55 gal drums and are planning to build a couple UDS's loosely based on the "Nelly Bly" smoker described on the Make Magazine website, but welding the components instead of pop-riveting them. They're going to be vertical smokers, external firebox connected by flexible duct so we can experiment with different kinds of smoke-generators and vary the flexible duct length to cold smoke and hot smoke. Our first question is about the chimney - the build plans use 3" diameter round duct to build an 18" tall chimney. Our barrels have nice 2" threaded pour-holes in the top. We were wondering if making a chimney out of electrical conduit (which we have in abundance since my son is an electrician) threaded into this opening would be workable. The pour hole is offset to near the outer rim of the top. Would the 2" diameter choke the air flow too much? Would the chimney being near the outer rim instead of being in the middle of the top?

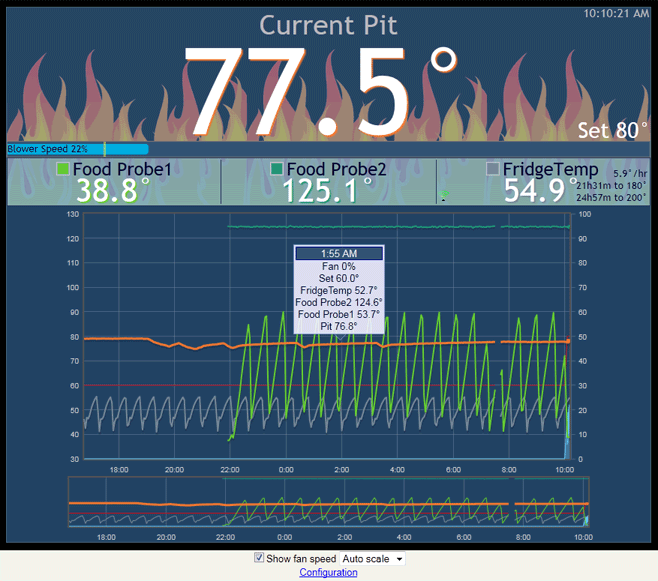

At least one of these UDS's is going to be a testbed system - I'm going to mount a handful of temperature sensors/pyrometers to measure smoke box temp at several locations, firebox temp, ambient temp, probably 2 spots along the flexible duct between the firebox and smoke box. All of this is going to be recorded by a Raspberry Pi microcomputer along with weight/type/time of wood additions. I'm going to display these on a time-based graph and eventually use it to tune a PID algorithm to recommend when to add more wood to keep the temp in a desired range. Anyone who has already done this have any advice on this? One question I have related to the temp probes is sealing the holes where the leads go in - do you think Sugru would work for chinking the lead holes in the smoke chamber since the firebox is separated from it? If not, what type of gasket do you recommend? I don't plan to store this where it'll be rained on so the chinking is more to control air flow than to make it waterproof.

We'd like to use smaller drums for the different kinds of fireboxes we want to experiment with, but have been unable to find any. Does anyone have ideas on how we could find some? Everything seems to come in plastic drums these days.

Our first firebox is going to be manual stick-fed but at some point I'd like to experiment with an augur-fed wood pellet/propane burner firebox (computer controlled, of course). Anyone have an augur pellet feed in good condition from a defunct pellet-fed smoker they'd like to sell?

Thanks in advance for the advice

Keith

P.S. Since I've been cautioned that posts without pics are useless, here's are the barrels:

At least one of these UDS's is going to be a testbed system - I'm going to mount a handful of temperature sensors/pyrometers to measure smoke box temp at several locations, firebox temp, ambient temp, probably 2 spots along the flexible duct between the firebox and smoke box. All of this is going to be recorded by a Raspberry Pi microcomputer along with weight/type/time of wood additions. I'm going to display these on a time-based graph and eventually use it to tune a PID algorithm to recommend when to add more wood to keep the temp in a desired range. Anyone who has already done this have any advice on this? One question I have related to the temp probes is sealing the holes where the leads go in - do you think Sugru would work for chinking the lead holes in the smoke chamber since the firebox is separated from it? If not, what type of gasket do you recommend? I don't plan to store this where it'll be rained on so the chinking is more to control air flow than to make it waterproof.

We'd like to use smaller drums for the different kinds of fireboxes we want to experiment with, but have been unable to find any. Does anyone have ideas on how we could find some? Everything seems to come in plastic drums these days.

Our first firebox is going to be manual stick-fed but at some point I'd like to experiment with an augur-fed wood pellet/propane burner firebox (computer controlled, of course). Anyone have an augur pellet feed in good condition from a defunct pellet-fed smoker they'd like to sell?

Thanks in advance for the advice

Keith

P.S. Since I've been cautioned that posts without pics are useless, here's are the barrels: