- Apr 21, 2015

- 72

- 13

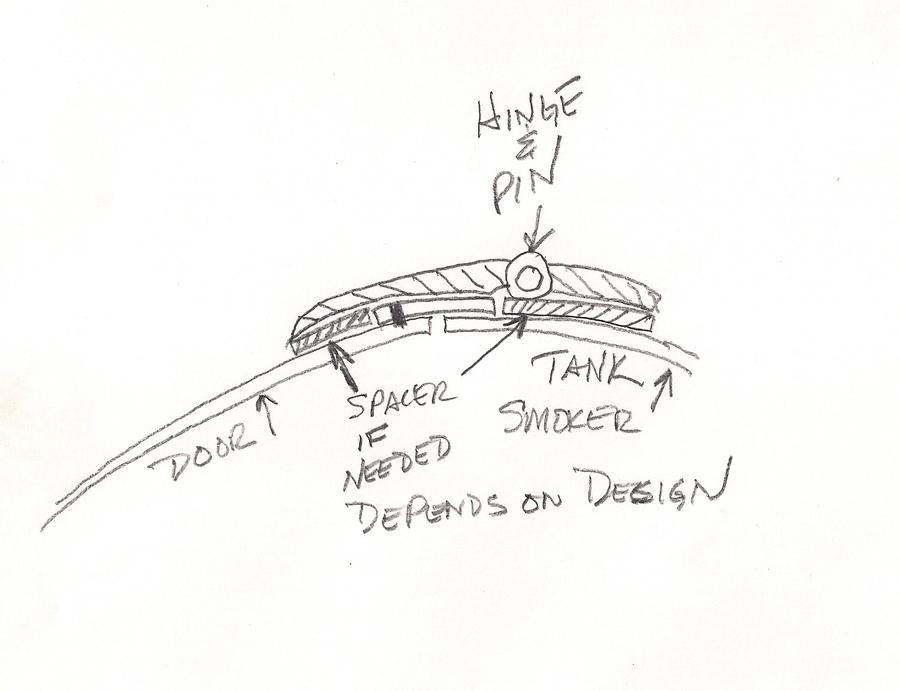

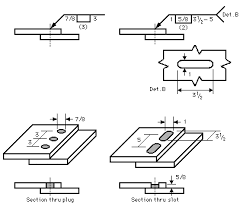

Cutting the doors out this weekend. We have them marked where we think they should be but before we open it up I was just curious if there was an "optimal" location for the top cut of the door. I believe now we have it located roughly three inches down from 12 o'clock. I've just been looking at pictures and it looks to me like most are cut pretty close to that.