- Jul 25, 2015

- 18

- 10

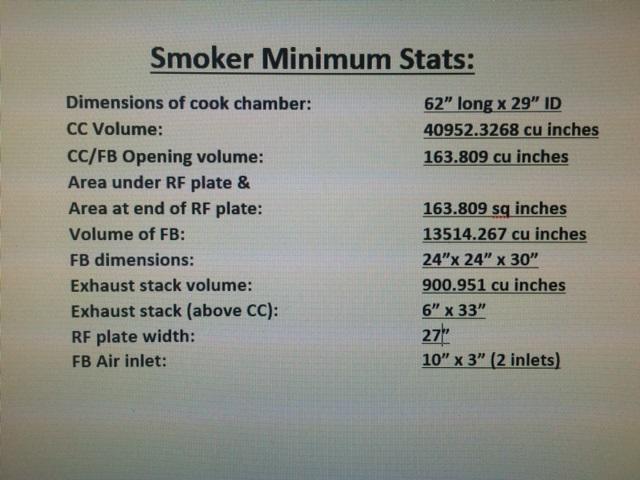

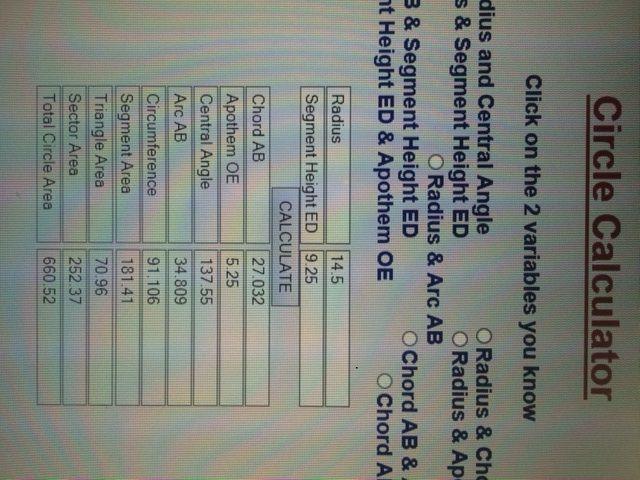

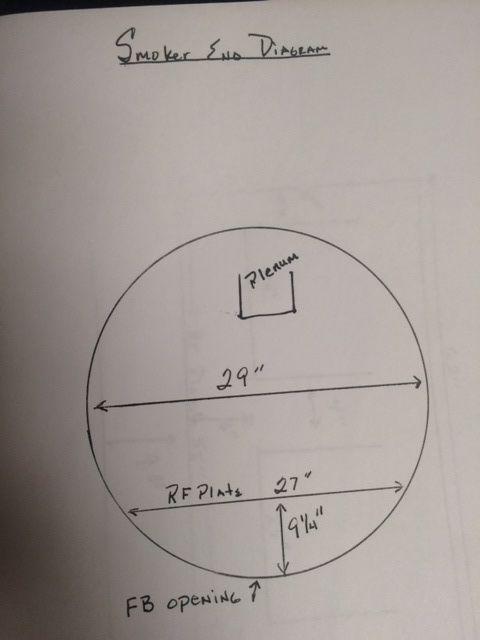

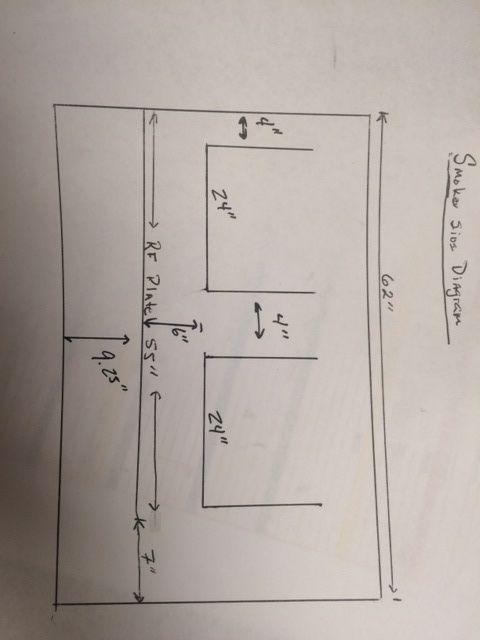

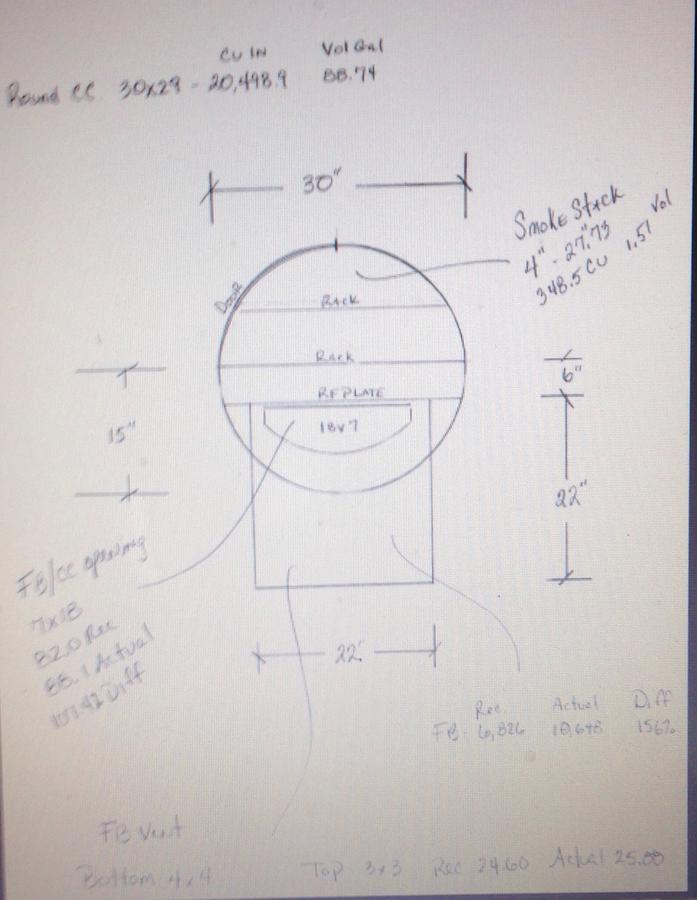

Can yall take a look at these figures? Do they look right? I used the calculator here, I did round the numbers for ease of cutting, measuring, etc. One of my questions is: It calls for at least 163.809 square inches at end of reverse flow plate, that tells me that if my RF plate is 27", I would need 6-7" between the end of RF plate and end of pit? that would make my RF plate approx. 27" x 56" or so, that seems like lots more than the recommended area of 163.809 square inches. Also that puts the RF plate and the cut for the FB opening about 9.25" or so from the bottom of cook chamber and it makes the FB/CC opening 181.41 sq inches. Is that too big? Will those figures work together?