- Aug 27, 2008

- 5,170

- 410

I acquired an AMNPS from Todd several months ago, and hot smoking with it in the Gourmet charcoal smoker seemed like a good challenge, so, I set out to make it happen.

These trials were based on NWDave's advice to not allow the smoke to pass through the charcoal fire, due to the translucency and possibly a break-down of the smoke when it passed through the fire. Heat from the coal-bed was also an issue, causing flare-up of the pellets. Then, the problem of low-oxygen environment had to be addressed as well. My theory was that I can avoid heat, food drippings and ash from the coal-bed by going into "the basement" with the AMNPS, and, if I contained the smoke until it passed above the fire, it would still add a good flavor to the food. This theory does hold true. Although I could not see smoke venting from the Gourmet's lid opening with a single-row burn, the smoke flavor was definitely there, and very smooth with the Pit-Master's Choice. I could detect the hickory and cherry, but not the maple or oak, mainly because I've not used them in the past. I must say the Pit-Master Blend is extremely smooth, flavorful, and carries a tantalizing aroma with pork and beef ribs.

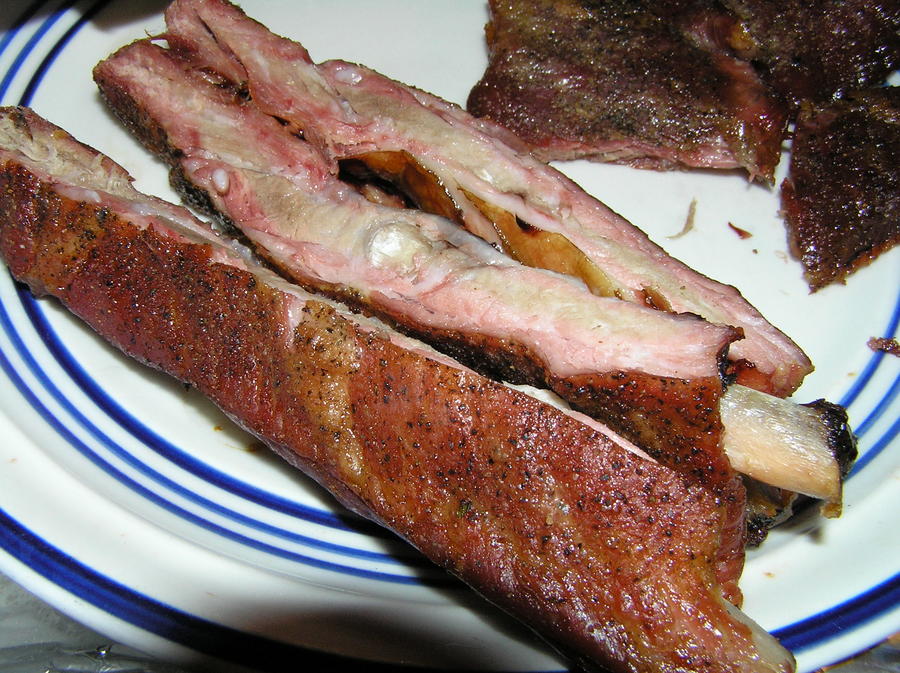

I ran with pea gravel in the water pan, about 2/3 full, then lined above the pea gravel with foil for drippings, which left a drip pan of about 3/4" - 1" deep. I ran the AMNPS cold for 30 minutes to be sure it would continue smoking, then added 1/2 chimney of Kingsford blue bag to season the freshly washed pea gravel and new pan (from Smoke n Grill). I waited until after I stopped hearing the water sizzling in the pan so I knew it steamed dry before adding my ribs. I never used sand or pea gravel in the pan before, so I decided to hold the temps back to around 200* (5,000ft elevation, also), for slower smoking and cooking for the first 90 minutes, then added more hot coals to bump to around 250* for another 2.5 hours before panning/tenting for 1 hour @ 275* in the Smoke Vault to finish. I went for a somewhat tender rib without alot of bark, just for simplicity and a change of pace. The results were tasy, moist and delicious:

Beef back ribs:

Small end of pork spare ribs:

Smoke from the vent of the AMNPS pan was never heavy, but very steady, and invisible at the Gourmet lid vent, but had that smoke aroma and sting to the eyes (the zen of smoke, IMHO). I loaded one tray/section to approx 2/3 up the sides, as it seemed to smoke a bit heavy during initial cold trials last night when I tested it with a foil box and vent stack, but as it turns out, a full tray would have been fine. I did do a little bit of light fabrication with a steel pan and vent stack this morning after finding I could not get a good seal between the bottom of the aluminum smoke box and the gourmet's fire pan without added weight. Also, I hammered down the slots on the bottom charcoal pan for combustion air so the pan would be as flat as possible (combustion air is now fed only through the upper round holes on the side of the fire pan), then added a rolled foil rim to the steel smoke pan and pressed it down tight to form the foil for a fairly decent seal until ash from the charcoal would begin to accumulate around the rim of the smoke pan. I had about 70-80% of the smoke escaping from the bottom of the foil smoke box, so I knew that wasn't going to fly well at all. Air is fed to the AMNPS through a 1-1/4" hole I already had cut during previous mods which is directly above the stock intake hole. After cold smoking, I installed a choke-plate over the intake air for the AMNPS, thinking that adding hot coals and building chamber temps would cause too much draft for the AMNPS, but I had to remove the choke-plate within 15 minutes of adding charcoal, as the pellets were starving for air and I had to blow them back to life before continuing to season the smoker mods. I positioned the AMNPS centered over the intake air hole, and oriented it so the vent stack for the smoke pan was on the long side of the AMNPS with the lit row away from the vent opening.

The smoke pan mod used today is a ceramic exterior coated steel pot, burned-out and wire-wheeled interior, cut down to 3" high, and is 11.25" diameter, with a 1-1/4" elbow vent stack rising 12" above the pan and fitted so as to almost touch the barrel of the smoke chamber when assembled and rises part-way up the side of the water pan, so it vents above the coal-bed. The coal grate is supported by 6" x 5/16" stove bolts, so it's approx 5-1/4" off the bottom of the charcoal pan.

Charcoal pan intake hole is 1-1/4", centered over the stock intake hole in the bottom pan/body, also note the slotted holes are hammered down to close them up fairly tight:

Intake control and plate (7lb-5oz beans can lid and heavy wire rod, mounted with sheet metal screw):

I opened up the original intake hole more with a jig-saw for more flow if needed:

So far, the intake provides adequate control for low and slow smoking. I do need to do a hotter smoke with a yard bird and see if it will kick out enough heat or not, otherwise, it works nicely.

The bulk of the rest of the mods I've done on the Gourmet are contained here (lid/barrel seal and lid vent...simple and easy as well):

http://www.smokingmeatforums.com/t/95616/brinkmann-gourmet-low-budget-mods-how-to-w-pics

OK, now on to how I got from Point A to Point B...smoke rising from vent on upper left of door opening...water pan is moved up for increased coal-bed size, coal ring, and elevated coal grate:

Smoke escaping upper left of door opening...not a lot, but then, I only filled the AMNPS 2/3 of the way up the side, so it's going to be lighter. It would be difficult to over-smoke something with this set-up, unless hot smoking very small items. I will go with a completely full pellet trough on the next round:

Cast iron coal grate with one section cut out with angle grinder to accommodate for the vent pipe...this grate is large enough to rest on the inside rim of the charcoal pan with three tabs...without the tabs, it would drop inside...one tab is visible on the lower right next to a leg-bolt:

Still have tons of room for ash fallout after a 4-hr smoke...could probably do a large pork butt again in this rig with these mods and the AMNPS, but I won't...I'm not quite quite that ambitious just yet...LOL!!!..:

Yep, tons of room for more ash...dammit, this mod may get me into trouble...I'm wanting to do a long smoke in it now, very badly:

Still venting some nice smoke while I looked things over before the moment of truth:

With the Smoke n Grill barrel for a back-ground:

The AMNPS after about a 4:45 burn time with 2/3 high load on one trough...almost done burning, but probably has another half-hour left in her, so, it was burning nice and slow with this particular smoker and her existing mods. I could likely go for 15-18 hours with a full load burning from one end in this rig:

The foil plug on the right of the charcoal pan is for a 1-1/4" hole I drilled to install a turkey fryer burner about a year ago...was just toying with ideas:

I could fore-go the aluminum foil seal on the rim of the smoke-pan if I keep some dry ashes to sprinkle around the rim after setting it all up for a smoke. The ashes will seal it up just fine by them selves.

Smoke-Pan & Stack Mod:

I had a helluva time welding different alloys and slightly dirty metals...ground off the ceramic coating, but with a gas-less wire-welder, it was still a bit of a chore:

Smoke seasoning from the first 4 hours of service...and a look at the tube insertion and hole type (1/4" hole drilled, then, cut at 8 points with jig-saw and slightly convinced with ball-peen hammer, then driven pipe in to fit snugly...saved me having to spend 30 bucks on an arbor and metal-capable hole-saw...welded on outside to seal it up):

All in all, I'd say the first run went really great. The lack of visible smoke out the Gourmet's lid vent is just a trivial issue, IMHO...can't see it, but it's definitely there...truly a thin blue smoke, but it never stopped smoking. Main thing is, with this mod, the AMNPS and pellets are protected from excessive heat, food drippings and ash, so it can just chug along at it's own pace for the duration. The use of the steel pot and pipe was a spur-of-the-moment thing for me...had it handy, had a few tools and decided to just roll with it...took a couple hours from the time I started looking over the feasibility until I had the AMNPS settled in for a test burn. When she looked happy, I decided to fire up a chimney of charcoal and get to rubbing some ribs for a smoke...piece a cake.

SECOND TEST

Got 'er fired up again for a Chix Thigh smoke. Still leaning more towards low and slow, starting @ ~225* with the exact same set-up as the first round. I did fill the center tray of the AMNPS to see how the upward draft from the centrally located inlet air effects the pellet burn, so I'll get pics of that after it burns through that stage.

I did notice on the first test that there was a couple charred pellets near the center of the row (you can see it in a few of those pics). I wasn't thinking along the lines of a possible issue at the time, but simply thought that it was a loose area where the pellets just weren't settled in quite right for good contact and a complete burn...could be either, I guess. I want to make sure it isn't a draft problem in that area, but if it just has a slight hiccup getting past it and carries forward from there, then it should be no major cause for concern, with the particular configuration I have, at least. If it causes the pellets to flare-up for a few minutes shouldn't hurt either, as long as it settles back into a slow smolder before killing it from too rapid of burn which may not spread to near-by pellets (that would probably take a high velocity air flow, I think).

What I'm not wanting to see is that it burns-up the hot pellets completely, before the heat ignites their neighbors...if so, I'll need to devise some sort of baffle to redirect the air outward from the intake opening, possibly elevating the AMNPS a 1/4" off bottom in the process. Just thinking of a plan of action to stay ahead of the game here if it does turn south on me...hmm, I guess I'm always doing that, huh? LOL!!! I did identify this one possible issue, which can be rectified shortly, if need be. Being I'm not doing a long smoke, this short-cut to getting into the middle of the second row will take us there..time will tell.

Anyway, here's the layout of the pellets...lit up pretty easily from an angle while leaving some space on the end with a tapered row of pellets. I did a couple re-lights until there was a nice sized base to keep it happy when the roof came down...just before the last re-light here:

1.25-hrs into the smoke, I had visible smoke from the vent of the Gourmet, which I concluded was due to an excess draft issue when the burn in the AMNPS got near the air inlet hole. The smoke intensity continued for 20-30 minutes, then began to to reduce it's intensity again and returned to no visible smoke after another 45 minutes or so. At the 2.75-hr mark, when adding another pound or so of briquettes to the fire, I had no smoke from the smoke pan vent stack, and no smoke aroma from the Gourmet's lid vent after loading it up with hot coals and closing it up. The pellets must have took off like a shot when the burn got over the inlet hole, then slowed down again, but I didn't have enough pellets to keep it going any longer. I'm betting it burned them all up prematurely...I'll check it out after dinner and see for sure.

Here's what I never saw yet from the AMNPS with this smoke-pan mod, until today...when I first saw this, I figured the possible air inlet issue had come out to challenge me...it shouldn't be a very difficult fix though:

It's probably best that I only loaded the center row for the thighs, being smaller cuts, else the smoke flavor could be a bit intense due to the suspected near flare-up of pellets...should be fine as is though. Probe in one larger thigh is reading 151* now (going for 170*), and chamber temps have been in the 210-220* range for most of the smoke, so they'll take a bit yet. It should render down quite a bit of fat under the skin going slower like this, and even without water in the pan, it's dark meat with the skin-on, so moisture should be fine with a ~170* finished temp.

My wheels are already turning for a baffle plate design, so I can get cracking on it first thing in the morning and have it ready to test with the Rib eye smoke for Mother's Day dinner. A bit of fine tuning and I think the AMNPS will be singing a smooth sweet tune.

I tried my best to keep the ashes from sifting into the AMNPS and skewing the view, but had my hands full here:

A light dusting of ash, but we can still see what I was looking at pretty well...the pellets did burn completely, so they had sufficient air, but was it too much near the center? Can't tell for sure just yet, but you can see signs of a cleaner burn (less smoke residue) near the center of the row on the side walls. Also, you can see a slightly more grey tint on the end where I lit the row...cooler burning and not as complete of combustion resulted:

I hadn't thought about checking this until tonight, but there's a strange residue pattern near the inlet air on the bottom...maybe nothing, but looks to be a slow turbulence causing some smoke to hang underneath...maybe from a more rapid burn causing a down-draft or swirling effect...if only I had high-temp compatible micro-optics to see it in action, then all the guess-work would be gone...but, where would the fun in that be? LOL!!!:

Now that I dumped the ashes, we can see more of the bare metal from a hotter burn near the center of the middle row. This was right above the air inlet, so my suspicions seems to have come to life. There's still a couple pellet remains stuck to the metal on either side of the hot-spot, which could indicate right when the heavy smoke started, as the burn would have become more erratic and incomplete at that point, and may not have spread evenly through the pellets. If you look closely, you can see the X from the support frame through the perforations. For clarification, the left end is where I lit the row of pellets:

Just slightly different angles to compensate for flash-glare:

Just a bit of investigating can reveal a lot, if you know what to look for, based on your suspicions. Either you find what you think should be, or you don't, but I think these pics show it very well what actually happened, along with what I saw coming out the vent when the smoke got heavy and then vanished completely...that was my sign, and now you know the rest of the story.

Next round, I need to do some light fab for an intake baffle, to smooth out this pellet burn rate, and I'll fire-up for Rib eye steaks to see if I get it dialed in closer for a full load of pellets on a long smoke, or a double-end burn. The center row burn control seems to be the key to making it happen with my current configuration and positioning, and that's my next fix. All things considered, it's not a major issue, but it can be made to perform a bit better, so the smoke stays lighter and the pellets can potentially burn longer as a result.

So, I give you a quick down & dirty no cost 15 minute baffle...I actually spent more time rounding up a tin snip, drill bit and drill than doing the cutting, crimping/trolling and fit-check. Didn't even use a tape measure, because I already knew I had approx 12/16" clearance from the AMNPS to the top of the smoke-pan.

And old Bush's Bake Beans 7lb-5oz can lid I had in my stash...I knew I'd find a use for it someday...I cut 8 "feet" to crimp and roll to size for a low-profile support, just enough to get the baffle up off the charcoal pan about 1/4" and provide a reasonably stable platform for the AMNPS to rest on. 3/16" holes were strategically drilled to keep the air away from direct upward flow into the pellets. I may find that a few smaller holes near the center will fine-tune it's performance even more. For now, it should stop the rapid burn I ran into on the chix thigh smoke, it just may slow the burn a bit towards the middle of the center row..shouldn't snuff them out, though.:

I didn't completely center the ASMNPS over the baffle before taking pics, so you can see the edge of it here:

Lower right support of the AMNPS is visible here and is elevated nicely, so air should traverse along the baffle and allow some to sneak up through the holes. The overall size of the baffle may be a bit larger than actually needed to do the job, but it's more stable than if I would go smaller. I will have be careful not to jar the smoker when this is all installed and running, otherwise it could upset the placement/positioning. You don't want to bump a char-coaler when fired-up anyway, else you have ash laden food...so, not a real draw-back at all:

I burned off the coating over an outdoor cooker propane burner, and she's ready for testing:

After another hot smoke, it appears that the pellets were slowed down above the baffle as planned, and there are a few which did not completely burn down to grey ash, but close, as they crumbled under light force...this so close to a complete burn without getting the excessive air flow issue I had yesterday...a couple real small holes a bit closer to the center is about as far as I'd want to go with any changes right now. I'm thinking this will roll along just fine as is, though. I did notice a nice light smoke from the vent on the Gourmet's lid today as well, and at first I was concerned, but then realized I had more depth of pellets in the AMNPS, so I left it alone. It chugged along nice and steady for almost 3-1/2 hours today, and always had that great smoke aroma from the Gourmet's vent, and a nice thin column of smoke rising, with a few very brief periods where it would nearly subside, but not completely. I can't ask it to do much more than it did today, because I don't see how it could get better:

The baffle got some nice smoke residue..it pulled it across towards the foreground instead of the rear, due to where the vent stack is located, and the rear row of the AMNPS was not loaded and burning, so that makes sense:

I don't see any possible issues now with giving the AMNPS a full load of pellets and stroking out a good long smoke from start to finish with the mods I've used. The baffle was the ticket to paradise.

THIRD TEST

I lit the AMNPS @ 7:45 AM this morning, briquettes shortly after, then prepped and dropped the bone-in 7.22lb butt in @ 8:30. I was debating starting this last night after work, but I'm not up for an all-nighter of fire tending, the weather is windy as hell with a chance for thunderstorms from last night through tomorrow, and I haven't had much success with the minion method, so I'll run with this today 'til she's done. No water in the pan, still using pea-gravel, no-foil and simple seasoning with garlic, salt and pepper. Meat, smoke and bark is my game today, nothing fancy, just the real deal. And, if the butt gets done too early for my liking of total run-time for the AMNPS, I can always toss some steaks and/or something else in to justify keeping the fire going longer...

I did have some trouble lighting the AMNPS, even with a torch, due to the wind. Just had to keep a small flame on the pellets for longer than normal, as the wind kept blowing it out. Then, I capped it off with the smoke-pan/stack mod while the briquettes were getting happy, just so I could make sure it would still burn under cover. Smoke seemed a bit thin at first, but it smells fine (actually, GREAT, as usual!) coming out the Gourmet vent, so we'll see if it smokes heavy enough. It should be a good test under adverse conditions today, as well. Lots of wind swirling around and possibly rain this afternoon/evening. Target temps are 210-215* due to the slightly smaller butt, even @ the 5,000 ft elevation, as I want to slow this way down for a nice long smoke run with the AMNPS...maybe 18 hours with no foiling to finish. Started in the 220* range for pasteurization of the surface, had a few minor spikes around 230*, but hopefully I can get closer to 210* or less for the duration.

I loaded the AMNPS this morning with a gap on the ends...I already know the ends will burn fine with the current mods, but want to know how it handles the transition from side to center rows, center row burn, and then around to the last row, so today should be the defining test. This amount of pellets should burn for 10-12 hours. I can't imaging needing/wanting smoke for longer than that, as 6-8 hours on a larger cut like a butt or packer brisket is about all they will take on. I'll keep tabs on the smoke output throughout the day and into the evening so we know what length it may run for with these mods:

I just added about a pound of hot briquettes a few minutes ago (1 hour into the smoke) to keep things rolling along smoothly.

I lost all smoke output somewhere during the 5th and 6th hour...odor from the vent diminished to the smell of cooking pork and a slight aroma from a hot charcoal fire only, so I knew something was awry. Opened the side door and a very light, thin smoke was venting from the pan stack, then shortly after, nothing. I suspect the vicious wind I'm dealing with did a number on the intake draft getting to the AMNSP causing a faster burn, although it may have been due to my closing down the intake to around 20-25% from the initial ~40% for fire control...this could have snuffed out the pellets...I had a bit too many briquettes burning and chamber temps were running near 240* for the first several hours. I should have removed some briqs with tongs instead. I'll get pics of the AMNPS after the butt comes out to rest before pulling. Smoke flavor should be sufficient after 5-6 hours, so I'm not worried about that, as internals were around 152* when the smoke stopped.

Butt stalled out after 7 hours @ 162*, with chamber temps dropping to 196* before I got more charcoal burning and added, and now I'm running around 210-215* after 8 hours. ( hour mark right now, and just climbed to 163* and I'm building up for a bit more fire, running 217* chamber temp. Guess I could have tried for 225-230* and been fine for a long smoke, you just never know when trying a new (to me) method without water in the pan on a hot smoke.

Wind was freakin' crazy all day, then just before dark, a nasty thunderstorm rolled through for about an hour, with heavy rain, hail and wind gusts that I nearly couldn't stand up in while trying to hold a tarp over myself and the smoker to keep from loosing dinner...I managed to catch a break in the rain just long enough to do a 4-point attachment of the tarp over my smoker for a quick-up roof, then the wind changed and I had to move the smoker...live and loaded with charcoal...that was just after 13 hours in...what a ride!

So, the winds were the culprit to the short smoke, as evidenced by the AMNPS's remains...it all burned up to ashes. Some didn't burn quite as hot, as there are some heavily charred pellets, though they were soft when I dropped 'em out to look at the burn pattern inside the AMNPS.

Just for reference if others want to try a long smoke with a similar mod in the Gourmet... ash pile after 16.5 hours in somewhat inclimate weather burner Kingsford blue bag...if you look closely, you'll notice the cast iron grate marks on the peak, running from 7:30 to 1:30 (clock hour-hand position)...so, not all that bad, even though it nearly completely covered the sides of the smoke-pan mod...I can see now that I used less coals towards the left than anywhere else...has to do with the hand I was using while loading hot coals with stainless 20" tongs:

The start of the burn is on the bottom of this shot...in the center is where I feel a bit more fine-tuning of the baffle plate is in order, as it appears to have slowed down there and wasn't burning hot enough for complete combustion, but I think we can all see from this smoke run that it can be made to work. The AMNPS may need a separate intake to compensate for windy conditions as I had today, or the addition of a choke-plate under the baffle could also be utilized for better intake control if these conditions are pre-existing and expected throughout the smoke:

Judging by the length of the slower burn after the start-up, maybe 90-120 minutes, then burning up faster, would coinicide with the time when the winds started really going south on me, so it all adds up and makes sense to me, now that I've seen the remains:

Just playing the camera here without a flash, using my white led headlamp on low power (15 Lumens) to see if the colors of the tan, and grey ash would be more in contrast with the light brown at the start of the burn:

The above was from back in late April to early May, if I recall, and I've been in limbo for further testing, mostly because we are under a ban on all solid fuel-fired outdoor cookers, open fires, etc (propane or electric heated cookers only), due to the extremely dry conditions here.

Hopefully, mother nature will allow for me to continue with this project soon, but I think you will have some pretty good ideas what you can do to make your AMNPS work in your pre-manufactured vertical charcoal smoker, regardless of the make/model, and possibly some of the UDS users may want to take a shot at it, as well.

Any questions on this mod, fire away...

Eric

These trials were based on NWDave's advice to not allow the smoke to pass through the charcoal fire, due to the translucency and possibly a break-down of the smoke when it passed through the fire. Heat from the coal-bed was also an issue, causing flare-up of the pellets. Then, the problem of low-oxygen environment had to be addressed as well. My theory was that I can avoid heat, food drippings and ash from the coal-bed by going into "the basement" with the AMNPS, and, if I contained the smoke until it passed above the fire, it would still add a good flavor to the food. This theory does hold true. Although I could not see smoke venting from the Gourmet's lid opening with a single-row burn, the smoke flavor was definitely there, and very smooth with the Pit-Master's Choice. I could detect the hickory and cherry, but not the maple or oak, mainly because I've not used them in the past. I must say the Pit-Master Blend is extremely smooth, flavorful, and carries a tantalizing aroma with pork and beef ribs.

I ran with pea gravel in the water pan, about 2/3 full, then lined above the pea gravel with foil for drippings, which left a drip pan of about 3/4" - 1" deep. I ran the AMNPS cold for 30 minutes to be sure it would continue smoking, then added 1/2 chimney of Kingsford blue bag to season the freshly washed pea gravel and new pan (from Smoke n Grill). I waited until after I stopped hearing the water sizzling in the pan so I knew it steamed dry before adding my ribs. I never used sand or pea gravel in the pan before, so I decided to hold the temps back to around 200* (5,000ft elevation, also), for slower smoking and cooking for the first 90 minutes, then added more hot coals to bump to around 250* for another 2.5 hours before panning/tenting for 1 hour @ 275* in the Smoke Vault to finish. I went for a somewhat tender rib without alot of bark, just for simplicity and a change of pace. The results were tasy, moist and delicious:

Beef back ribs:

Small end of pork spare ribs:

Smoke from the vent of the AMNPS pan was never heavy, but very steady, and invisible at the Gourmet lid vent, but had that smoke aroma and sting to the eyes (the zen of smoke, IMHO). I loaded one tray/section to approx 2/3 up the sides, as it seemed to smoke a bit heavy during initial cold trials last night when I tested it with a foil box and vent stack, but as it turns out, a full tray would have been fine. I did do a little bit of light fabrication with a steel pan and vent stack this morning after finding I could not get a good seal between the bottom of the aluminum smoke box and the gourmet's fire pan without added weight. Also, I hammered down the slots on the bottom charcoal pan for combustion air so the pan would be as flat as possible (combustion air is now fed only through the upper round holes on the side of the fire pan), then added a rolled foil rim to the steel smoke pan and pressed it down tight to form the foil for a fairly decent seal until ash from the charcoal would begin to accumulate around the rim of the smoke pan. I had about 70-80% of the smoke escaping from the bottom of the foil smoke box, so I knew that wasn't going to fly well at all. Air is fed to the AMNPS through a 1-1/4" hole I already had cut during previous mods which is directly above the stock intake hole. After cold smoking, I installed a choke-plate over the intake air for the AMNPS, thinking that adding hot coals and building chamber temps would cause too much draft for the AMNPS, but I had to remove the choke-plate within 15 minutes of adding charcoal, as the pellets were starving for air and I had to blow them back to life before continuing to season the smoker mods. I positioned the AMNPS centered over the intake air hole, and oriented it so the vent stack for the smoke pan was on the long side of the AMNPS with the lit row away from the vent opening.

The smoke pan mod used today is a ceramic exterior coated steel pot, burned-out and wire-wheeled interior, cut down to 3" high, and is 11.25" diameter, with a 1-1/4" elbow vent stack rising 12" above the pan and fitted so as to almost touch the barrel of the smoke chamber when assembled and rises part-way up the side of the water pan, so it vents above the coal-bed. The coal grate is supported by 6" x 5/16" stove bolts, so it's approx 5-1/4" off the bottom of the charcoal pan.

Charcoal pan intake hole is 1-1/4", centered over the stock intake hole in the bottom pan/body, also note the slotted holes are hammered down to close them up fairly tight:

Intake control and plate (7lb-5oz beans can lid and heavy wire rod, mounted with sheet metal screw):

I opened up the original intake hole more with a jig-saw for more flow if needed:

So far, the intake provides adequate control for low and slow smoking. I do need to do a hotter smoke with a yard bird and see if it will kick out enough heat or not, otherwise, it works nicely.

The bulk of the rest of the mods I've done on the Gourmet are contained here (lid/barrel seal and lid vent...simple and easy as well):

http://www.smokingmeatforums.com/t/95616/brinkmann-gourmet-low-budget-mods-how-to-w-pics

OK, now on to how I got from Point A to Point B...smoke rising from vent on upper left of door opening...water pan is moved up for increased coal-bed size, coal ring, and elevated coal grate:

Smoke escaping upper left of door opening...not a lot, but then, I only filled the AMNPS 2/3 of the way up the side, so it's going to be lighter. It would be difficult to over-smoke something with this set-up, unless hot smoking very small items. I will go with a completely full pellet trough on the next round:

Cast iron coal grate with one section cut out with angle grinder to accommodate for the vent pipe...this grate is large enough to rest on the inside rim of the charcoal pan with three tabs...without the tabs, it would drop inside...one tab is visible on the lower right next to a leg-bolt:

Still have tons of room for ash fallout after a 4-hr smoke...could probably do a large pork butt again in this rig with these mods and the AMNPS, but I won't...I'm not quite quite that ambitious just yet...LOL!!!..:

Yep, tons of room for more ash...dammit, this mod may get me into trouble...I'm wanting to do a long smoke in it now, very badly:

Still venting some nice smoke while I looked things over before the moment of truth:

With the Smoke n Grill barrel for a back-ground:

The AMNPS after about a 4:45 burn time with 2/3 high load on one trough...almost done burning, but probably has another half-hour left in her, so, it was burning nice and slow with this particular smoker and her existing mods. I could likely go for 15-18 hours with a full load burning from one end in this rig:

The foil plug on the right of the charcoal pan is for a 1-1/4" hole I drilled to install a turkey fryer burner about a year ago...was just toying with ideas:

I could fore-go the aluminum foil seal on the rim of the smoke-pan if I keep some dry ashes to sprinkle around the rim after setting it all up for a smoke. The ashes will seal it up just fine by them selves.

Smoke-Pan & Stack Mod:

I had a helluva time welding different alloys and slightly dirty metals...ground off the ceramic coating, but with a gas-less wire-welder, it was still a bit of a chore:

Smoke seasoning from the first 4 hours of service...and a look at the tube insertion and hole type (1/4" hole drilled, then, cut at 8 points with jig-saw and slightly convinced with ball-peen hammer, then driven pipe in to fit snugly...saved me having to spend 30 bucks on an arbor and metal-capable hole-saw...welded on outside to seal it up):

All in all, I'd say the first run went really great. The lack of visible smoke out the Gourmet's lid vent is just a trivial issue, IMHO...can't see it, but it's definitely there...truly a thin blue smoke, but it never stopped smoking. Main thing is, with this mod, the AMNPS and pellets are protected from excessive heat, food drippings and ash, so it can just chug along at it's own pace for the duration. The use of the steel pot and pipe was a spur-of-the-moment thing for me...had it handy, had a few tools and decided to just roll with it...took a couple hours from the time I started looking over the feasibility until I had the AMNPS settled in for a test burn. When she looked happy, I decided to fire up a chimney of charcoal and get to rubbing some ribs for a smoke...piece a cake.

SECOND TEST

Got 'er fired up again for a Chix Thigh smoke. Still leaning more towards low and slow, starting @ ~225* with the exact same set-up as the first round. I did fill the center tray of the AMNPS to see how the upward draft from the centrally located inlet air effects the pellet burn, so I'll get pics of that after it burns through that stage.

I did notice on the first test that there was a couple charred pellets near the center of the row (you can see it in a few of those pics). I wasn't thinking along the lines of a possible issue at the time, but simply thought that it was a loose area where the pellets just weren't settled in quite right for good contact and a complete burn...could be either, I guess. I want to make sure it isn't a draft problem in that area, but if it just has a slight hiccup getting past it and carries forward from there, then it should be no major cause for concern, with the particular configuration I have, at least. If it causes the pellets to flare-up for a few minutes shouldn't hurt either, as long as it settles back into a slow smolder before killing it from too rapid of burn which may not spread to near-by pellets (that would probably take a high velocity air flow, I think).

What I'm not wanting to see is that it burns-up the hot pellets completely, before the heat ignites their neighbors...if so, I'll need to devise some sort of baffle to redirect the air outward from the intake opening, possibly elevating the AMNPS a 1/4" off bottom in the process. Just thinking of a plan of action to stay ahead of the game here if it does turn south on me...hmm, I guess I'm always doing that, huh? LOL!!! I did identify this one possible issue, which can be rectified shortly, if need be. Being I'm not doing a long smoke, this short-cut to getting into the middle of the second row will take us there..time will tell.

Anyway, here's the layout of the pellets...lit up pretty easily from an angle while leaving some space on the end with a tapered row of pellets. I did a couple re-lights until there was a nice sized base to keep it happy when the roof came down...just before the last re-light here:

1.25-hrs into the smoke, I had visible smoke from the vent of the Gourmet, which I concluded was due to an excess draft issue when the burn in the AMNPS got near the air inlet hole. The smoke intensity continued for 20-30 minutes, then began to to reduce it's intensity again and returned to no visible smoke after another 45 minutes or so. At the 2.75-hr mark, when adding another pound or so of briquettes to the fire, I had no smoke from the smoke pan vent stack, and no smoke aroma from the Gourmet's lid vent after loading it up with hot coals and closing it up. The pellets must have took off like a shot when the burn got over the inlet hole, then slowed down again, but I didn't have enough pellets to keep it going any longer. I'm betting it burned them all up prematurely...I'll check it out after dinner and see for sure.

Here's what I never saw yet from the AMNPS with this smoke-pan mod, until today...when I first saw this, I figured the possible air inlet issue had come out to challenge me...it shouldn't be a very difficult fix though:

It's probably best that I only loaded the center row for the thighs, being smaller cuts, else the smoke flavor could be a bit intense due to the suspected near flare-up of pellets...should be fine as is though. Probe in one larger thigh is reading 151* now (going for 170*), and chamber temps have been in the 210-220* range for most of the smoke, so they'll take a bit yet. It should render down quite a bit of fat under the skin going slower like this, and even without water in the pan, it's dark meat with the skin-on, so moisture should be fine with a ~170* finished temp.

My wheels are already turning for a baffle plate design, so I can get cracking on it first thing in the morning and have it ready to test with the Rib eye smoke for Mother's Day dinner. A bit of fine tuning and I think the AMNPS will be singing a smooth sweet tune.

I tried my best to keep the ashes from sifting into the AMNPS and skewing the view, but had my hands full here:

A light dusting of ash, but we can still see what I was looking at pretty well...the pellets did burn completely, so they had sufficient air, but was it too much near the center? Can't tell for sure just yet, but you can see signs of a cleaner burn (less smoke residue) near the center of the row on the side walls. Also, you can see a slightly more grey tint on the end where I lit the row...cooler burning and not as complete of combustion resulted:

I hadn't thought about checking this until tonight, but there's a strange residue pattern near the inlet air on the bottom...maybe nothing, but looks to be a slow turbulence causing some smoke to hang underneath...maybe from a more rapid burn causing a down-draft or swirling effect...if only I had high-temp compatible micro-optics to see it in action, then all the guess-work would be gone...but, where would the fun in that be? LOL!!!:

Now that I dumped the ashes, we can see more of the bare metal from a hotter burn near the center of the middle row. This was right above the air inlet, so my suspicions seems to have come to life. There's still a couple pellet remains stuck to the metal on either side of the hot-spot, which could indicate right when the heavy smoke started, as the burn would have become more erratic and incomplete at that point, and may not have spread evenly through the pellets. If you look closely, you can see the X from the support frame through the perforations. For clarification, the left end is where I lit the row of pellets:

Just slightly different angles to compensate for flash-glare:

Just a bit of investigating can reveal a lot, if you know what to look for, based on your suspicions. Either you find what you think should be, or you don't, but I think these pics show it very well what actually happened, along with what I saw coming out the vent when the smoke got heavy and then vanished completely...that was my sign, and now you know the rest of the story.

Next round, I need to do some light fab for an intake baffle, to smooth out this pellet burn rate, and I'll fire-up for Rib eye steaks to see if I get it dialed in closer for a full load of pellets on a long smoke, or a double-end burn. The center row burn control seems to be the key to making it happen with my current configuration and positioning, and that's my next fix. All things considered, it's not a major issue, but it can be made to perform a bit better, so the smoke stays lighter and the pellets can potentially burn longer as a result.

So, I give you a quick down & dirty no cost 15 minute baffle...I actually spent more time rounding up a tin snip, drill bit and drill than doing the cutting, crimping/trolling and fit-check. Didn't even use a tape measure, because I already knew I had approx 12/16" clearance from the AMNPS to the top of the smoke-pan.

And old Bush's Bake Beans 7lb-5oz can lid I had in my stash...I knew I'd find a use for it someday...I cut 8 "feet" to crimp and roll to size for a low-profile support, just enough to get the baffle up off the charcoal pan about 1/4" and provide a reasonably stable platform for the AMNPS to rest on. 3/16" holes were strategically drilled to keep the air away from direct upward flow into the pellets. I may find that a few smaller holes near the center will fine-tune it's performance even more. For now, it should stop the rapid burn I ran into on the chix thigh smoke, it just may slow the burn a bit towards the middle of the center row..shouldn't snuff them out, though.:

I didn't completely center the ASMNPS over the baffle before taking pics, so you can see the edge of it here:

Lower right support of the AMNPS is visible here and is elevated nicely, so air should traverse along the baffle and allow some to sneak up through the holes. The overall size of the baffle may be a bit larger than actually needed to do the job, but it's more stable than if I would go smaller. I will have be careful not to jar the smoker when this is all installed and running, otherwise it could upset the placement/positioning. You don't want to bump a char-coaler when fired-up anyway, else you have ash laden food...so, not a real draw-back at all:

I burned off the coating over an outdoor cooker propane burner, and she's ready for testing:

After another hot smoke, it appears that the pellets were slowed down above the baffle as planned, and there are a few which did not completely burn down to grey ash, but close, as they crumbled under light force...this so close to a complete burn without getting the excessive air flow issue I had yesterday...a couple real small holes a bit closer to the center is about as far as I'd want to go with any changes right now. I'm thinking this will roll along just fine as is, though. I did notice a nice light smoke from the vent on the Gourmet's lid today as well, and at first I was concerned, but then realized I had more depth of pellets in the AMNPS, so I left it alone. It chugged along nice and steady for almost 3-1/2 hours today, and always had that great smoke aroma from the Gourmet's vent, and a nice thin column of smoke rising, with a few very brief periods where it would nearly subside, but not completely. I can't ask it to do much more than it did today, because I don't see how it could get better:

The baffle got some nice smoke residue..it pulled it across towards the foreground instead of the rear, due to where the vent stack is located, and the rear row of the AMNPS was not loaded and burning, so that makes sense:

I don't see any possible issues now with giving the AMNPS a full load of pellets and stroking out a good long smoke from start to finish with the mods I've used. The baffle was the ticket to paradise.

THIRD TEST

I lit the AMNPS @ 7:45 AM this morning, briquettes shortly after, then prepped and dropped the bone-in 7.22lb butt in @ 8:30. I was debating starting this last night after work, but I'm not up for an all-nighter of fire tending, the weather is windy as hell with a chance for thunderstorms from last night through tomorrow, and I haven't had much success with the minion method, so I'll run with this today 'til she's done. No water in the pan, still using pea-gravel, no-foil and simple seasoning with garlic, salt and pepper. Meat, smoke and bark is my game today, nothing fancy, just the real deal. And, if the butt gets done too early for my liking of total run-time for the AMNPS, I can always toss some steaks and/or something else in to justify keeping the fire going longer...

I did have some trouble lighting the AMNPS, even with a torch, due to the wind. Just had to keep a small flame on the pellets for longer than normal, as the wind kept blowing it out. Then, I capped it off with the smoke-pan/stack mod while the briquettes were getting happy, just so I could make sure it would still burn under cover. Smoke seemed a bit thin at first, but it smells fine (actually, GREAT, as usual!) coming out the Gourmet vent, so we'll see if it smokes heavy enough. It should be a good test under adverse conditions today, as well. Lots of wind swirling around and possibly rain this afternoon/evening. Target temps are 210-215* due to the slightly smaller butt, even @ the 5,000 ft elevation, as I want to slow this way down for a nice long smoke run with the AMNPS...maybe 18 hours with no foiling to finish. Started in the 220* range for pasteurization of the surface, had a few minor spikes around 230*, but hopefully I can get closer to 210* or less for the duration.

I loaded the AMNPS this morning with a gap on the ends...I already know the ends will burn fine with the current mods, but want to know how it handles the transition from side to center rows, center row burn, and then around to the last row, so today should be the defining test. This amount of pellets should burn for 10-12 hours. I can't imaging needing/wanting smoke for longer than that, as 6-8 hours on a larger cut like a butt or packer brisket is about all they will take on. I'll keep tabs on the smoke output throughout the day and into the evening so we know what length it may run for with these mods:

I just added about a pound of hot briquettes a few minutes ago (1 hour into the smoke) to keep things rolling along smoothly.

I lost all smoke output somewhere during the 5th and 6th hour...odor from the vent diminished to the smell of cooking pork and a slight aroma from a hot charcoal fire only, so I knew something was awry. Opened the side door and a very light, thin smoke was venting from the pan stack, then shortly after, nothing. I suspect the vicious wind I'm dealing with did a number on the intake draft getting to the AMNSP causing a faster burn, although it may have been due to my closing down the intake to around 20-25% from the initial ~40% for fire control...this could have snuffed out the pellets...I had a bit too many briquettes burning and chamber temps were running near 240* for the first several hours. I should have removed some briqs with tongs instead. I'll get pics of the AMNPS after the butt comes out to rest before pulling. Smoke flavor should be sufficient after 5-6 hours, so I'm not worried about that, as internals were around 152* when the smoke stopped.

Butt stalled out after 7 hours @ 162*, with chamber temps dropping to 196* before I got more charcoal burning and added, and now I'm running around 210-215* after 8 hours. ( hour mark right now, and just climbed to 163* and I'm building up for a bit more fire, running 217* chamber temp. Guess I could have tried for 225-230* and been fine for a long smoke, you just never know when trying a new (to me) method without water in the pan on a hot smoke.

Wind was freakin' crazy all day, then just before dark, a nasty thunderstorm rolled through for about an hour, with heavy rain, hail and wind gusts that I nearly couldn't stand up in while trying to hold a tarp over myself and the smoker to keep from loosing dinner...I managed to catch a break in the rain just long enough to do a 4-point attachment of the tarp over my smoker for a quick-up roof, then the wind changed and I had to move the smoker...live and loaded with charcoal...that was just after 13 hours in...what a ride!

So, the winds were the culprit to the short smoke, as evidenced by the AMNPS's remains...it all burned up to ashes. Some didn't burn quite as hot, as there are some heavily charred pellets, though they were soft when I dropped 'em out to look at the burn pattern inside the AMNPS.

Just for reference if others want to try a long smoke with a similar mod in the Gourmet... ash pile after 16.5 hours in somewhat inclimate weather burner Kingsford blue bag...if you look closely, you'll notice the cast iron grate marks on the peak, running from 7:30 to 1:30 (clock hour-hand position)...so, not all that bad, even though it nearly completely covered the sides of the smoke-pan mod...I can see now that I used less coals towards the left than anywhere else...has to do with the hand I was using while loading hot coals with stainless 20" tongs:

The start of the burn is on the bottom of this shot...in the center is where I feel a bit more fine-tuning of the baffle plate is in order, as it appears to have slowed down there and wasn't burning hot enough for complete combustion, but I think we can all see from this smoke run that it can be made to work. The AMNPS may need a separate intake to compensate for windy conditions as I had today, or the addition of a choke-plate under the baffle could also be utilized for better intake control if these conditions are pre-existing and expected throughout the smoke:

Judging by the length of the slower burn after the start-up, maybe 90-120 minutes, then burning up faster, would coinicide with the time when the winds started really going south on me, so it all adds up and makes sense to me, now that I've seen the remains:

Just playing the camera here without a flash, using my white led headlamp on low power (15 Lumens) to see if the colors of the tan, and grey ash would be more in contrast with the light brown at the start of the burn:

The above was from back in late April to early May, if I recall, and I've been in limbo for further testing, mostly because we are under a ban on all solid fuel-fired outdoor cookers, open fires, etc (propane or electric heated cookers only), due to the extremely dry conditions here.

Hopefully, mother nature will allow for me to continue with this project soon, but I think you will have some pretty good ideas what you can do to make your AMNPS work in your pre-manufactured vertical charcoal smoker, regardless of the make/model, and possibly some of the UDS users may want to take a shot at it, as well.

Any questions on this mod, fire away...

Eric

Last edited: