Insulated dual cabinet smoker

- Thread starter ahumadora

- Start date

-

Some of the links on this forum allow SMF, at no cost to you, to earn a small commission when you click through and make a purchase. Let me know if you have any questions about this.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

SMF is reader-supported. When you buy through links on our site, we may earn an affiliate commission.

A commercial smoker using a design I have been kicking around for a while. I should have it done in a week or so if other work permits. Will have 10 racks of 850x950mm with 190mm clearance between each rack. Has a center firebox with 2 lower warming drawers on the outside. Heat goes up the internal chimneys then down through the racks where it enters in the lower part of a false wall the up the outside walls to vent. Sheetmetal is 2mm (#14).

Can't wait to eat some BBQ out of it.

Very nice design of a "reverse flow vertical smoker".... Can't wait to see it operate.....

It doesn't have an owner yet, so will have to be the shop pit until it sells.

Installing the roof panels. I figured it wouldn't get hot enough to use high heat paint, so just used the good old red oxide primer. I will paint the outside the same color, but in Satin.

The lower area will be a simple warming drawer.

This is the center wall with grease drain.

Hard to see but there is a grease drain and the smoke enters at the bottom of the false wall. I used the off cuts to make the false wall as I was out of sheet metal and to save $.

Back of firebox. There was a bunch of welding to do, so I got the young guy in the shop to do it as he wants the practice. I probably will put in a sacrificial plate in the top of the firebox for better dispersion of heat and longevity.

The lower area will be a simple warming drawer.

This is the center wall with grease drain.

Hard to see but there is a grease drain and the smoke enters at the bottom of the false wall. I used the off cuts to make the false wall as I was out of sheet metal and to save $.

Back of firebox. There was a bunch of welding to do, so I got the young guy in the shop to do it as he wants the practice. I probably will put in a sacrificial plate in the top of the firebox for better dispersion of heat and longevity.

Nearly done, I will weld the doors on tomorrow. I added another 1/4" plate to the inside upper part of the firebox to help disperse the heat. tomorrow I hopefully will throw some wood at it and see what it does.

smokinhawgbbq

Smoke Blower

Looks Awsome !! I might borrow a few ideas for a double door build I have to do for a friend's new resteraunt.

Mike

Mike

......

....... Smoke.... we want to see smoke.......

....... Smoke.... we want to see smoke.......

Where does smoke exit the Cook Chamber ?? Are those the exhaust stacks I see on top...??

Where does smoke exit the Cook Chamber ?? Are those the exhaust stacks I see on top...??

Last edited:

Dave,

You will have to wait until next week to see smoke as it is vacations here Friday and Monday. I also have a bunch of running around to do tomorrow sourcing parts for other smokers.

The outside wall where the 4x2" is on the flat edge has a false wall on the inside.

Here's the false wall welded to the parrilla guides. hery hard to see but there is a 2" gap down by where the F clamp is.

On the right side of this pic you see I placed the vertical 4x2 on it's flat edge to give me a 2" gap for the false wall then 2" for the insulation. The smoke enters at the bottom of the angled plate.

another shot of the false wall. You can't see it in the pic, but there is a 2" gap at the bottom and a hole for the grease drain in the center of the photo.

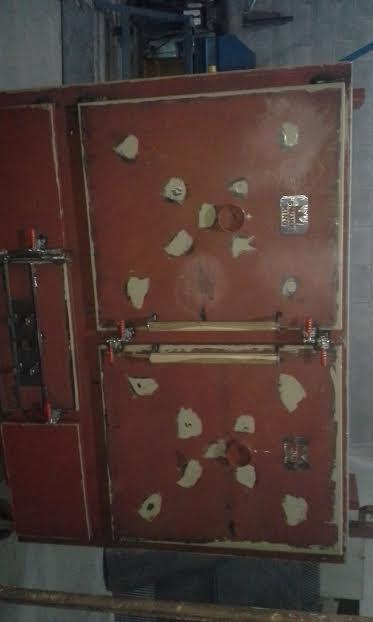

Looks like crap at the moment as I used a filler paste to cover the grinding marks and seams. Next week I will throw some paint at it.

The 2 outside lower cabinets are ovens ( no smoke)

Doors welded on.

You will have to wait until next week to see smoke as it is vacations here Friday and Monday. I also have a bunch of running around to do tomorrow sourcing parts for other smokers.

The outside wall where the 4x2" is on the flat edge has a false wall on the inside.

Here's the false wall welded to the parrilla guides. hery hard to see but there is a 2" gap down by where the F clamp is.

On the right side of this pic you see I placed the vertical 4x2 on it's flat edge to give me a 2" gap for the false wall then 2" for the insulation. The smoke enters at the bottom of the angled plate.

another shot of the false wall. You can't see it in the pic, but there is a 2" gap at the bottom and a hole for the grease drain in the center of the photo.

Looks like crap at the moment as I used a filler paste to cover the grinding marks and seams. Next week I will throw some paint at it.

The 2 outside lower cabinets are ovens ( no smoke)

Doors welded on.

That huge chunk of steel in the bottom of the photo is going to be my welding table.

Sorry about the crappy photos as it is the shortest day of the year here. Sun is always low in the sky all day. Tomorrow I will fire it up and see what happens.

Was down to about 40F when I fired it up this morning. Hence the white smoke.

Pork shoulder and a rack of ribs with the rest of the off cuts.. I made pulled pork

I was going to do some testing today but my laser thermometer took a dump. First redings where a 30f split top to bottom, but was barely up to temp. It wanted to run hot all day at 250-275. I did take it up to 400F to burn off the crap a bit. Strange thing was it always favored the right hand exhuast even though there was not wind and was level.

Pork shoulder and a rack of ribs with the rest of the off cuts.. I made pulled pork

I was going to do some testing today but my laser thermometer took a dump. First redings where a 30f split top to bottom, but was barely up to temp. It wanted to run hot all day at 250-275. I did take it up to 400F to burn off the crap a bit. Strange thing was it always favored the right hand exhuast even though there was not wind and was level.

Last edited:

Let me know if you need the CAD designs for the chassis. After todays test run I would also make a few little tweaks.

Looks Awsome !! I might borrow a few ideas for a double door build I have to do for a friend's new resteraunt.

Mike

Thanks Dave.

The BBQ was good today, but not up to competition standards. I was too busy working on making a gantry as I have 6 250 gallon propane tanks coming soon.

I also need the gantry so I can move that 1000kg ripper off a bulldozer and flip it over to make a table. The other part is in the background and am going to make a hydraulic press out of it.

Maybe this weekend i will have time to do some Beef ribs without too much interuption..

The BBQ was good today, but not up to competition standards. I was too busy working on making a gantry as I have 6 250 gallon propane tanks coming soon.

I also need the gantry so I can move that 1000kg ripper off a bulldozer and flip it over to make a table. The other part is in the background and am going to make a hydraulic press out of it.

Maybe this weekend i will have time to do some Beef ribs without too much interuption..

SmokingMeatForums.com is reader supported and as an Amazon Associate, we may earn commissions from qualifying purchases.

Similar threads

- Replies

- 4

- Views

- 408

- Replies

- 4

- Views

- 2K

- Replies

- 0

- Views

- 275

- Replies

- 0

- Views

- 750

- Replies

- 11

- Views

- 389

- Replies

- 11

- Views

- 3K

Hot Threads

-

Spammer PMs, Anybody Else?

- Started by chilerelleno

- Replies: 66

- Blowing Smoke Around the Smoker.

-

Lost my dad yesterday

- Started by normanaj

- Replies: 40

- Blowing Smoke Around the Smoker.

-

On the Edge of Trying Sausage Making

- Started by BrianGSDTexoma

- Replies: 35

- Sausage

-

Took a stroll this afternoon

- Started by Buckeyedude

- Replies: 33

- Field and Stream

-

Featured Blackened Rockfish...

- Started by Gonna Smoke

- Replies: 33

- Fish