Hi everyone, I recently purchased a 2nd hand smoker which the guy had built himself. It's made from thick flue steel so if I can get it up and running will probably be better than anything I can afford to buy from new (I am in the UK where these things aren't commonplace).

However there is a problem. I don't seem to be able to sustain a fire large or hot enough to get the cooking chamber (CC) up to temperature - at least not without a lot of work (such as burning fine kindling which requires constant replenishing, poking and topping up).

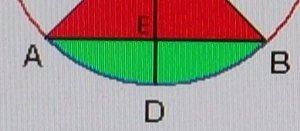

The design is as follows:

So it's not a 'true' reverse flow smoker as the floor plate (2 in diagram) is perforated (more on that later).

The major quirk to the design however is that the Firebox (FB) is separated from CC via a length of flue steel (ID = 4.5" len = 4.5").

First cook:

My first experiment was to use the smoker in the most basic way possible, leaving everything as you see above. I lit a chimney of charcoal, let it get up to heat, put it in the FB and put small oak sticks on the top.

There was thick smoke from the chimney and the wood would smoulder pathetically. I place the coals on the side closest to the CC and under the connecting pipe between the FB and CC. I placed wood I was about to burn on the other side to it was nice and warm when it was to go on the fire.

Second cook:

I did some investigation online and it seems as though the issue might be that the fire was not hot or big enough. So i tried it again but this time with 2 full chimneys - I experience almost exactly the same issue as before.

Experimentation:

I took the opportunity to try a few things and see what was and wasn't working. The first thing I did was experiment with cracking the door of the FB open, this had a good effect. Instead of smouldering the wood would burn with flame. However a lot of heat and smoke was lost though the open door - so the CC didn't really get that much hotter.

I also took the opportunity to remove the internal baffling so the smoke went straight into CC at the side closest the FB and straight out of the chimney. When I did this in-conjunction with the door being cracked I was able to just about get a decent cook (of course only in the area very close to stack - so not big enough for anything other than a small chicken.

Third Cook:

I decided I would dispense with the peculiarity of this design with the perforated floor plate and try and convert it into a normal reverse flow smoker. To do this I used foil tape to seal up all of the joins and the perforations. I pulled the floor plate towards the FB a bit create a gap at the far end of the CC to the smoke to perform it's U-turn.

Rather depressingly at first I was experiencing all of the same issues as before. Thick white smoker, struggling to keep wood burning properly, it just wanted to smoulder.

I then decide to increase the the size of the stack. With a DIY extension:

This had a clear positive impact on the draw speed and seemed to make thing a tiny bit more stable. But not a lot.

I then decide to move the fire from the side closest the CC to the side closest the inlet. And at last I was able to burn wood with a flame with the fire box door close. However the fire is rather unstable - it only likes to burn fine kindling which require topping up and poking frequently and even then from time to time it'd still decide it was going to self extinguish.

Early Prediction:

A this point I am thinking to myself the issue is surely that the fire is not getting enough clean air in to burn hot and constantly enough.

Maths:

So in my research on trying to fix this issue I ran across this post on this forum:

https://www.smokingmeatforums.com/t...eady-to-use-rev5-6-19-15.172425/#post_1264161

Here is how the stats weigh up for my smoker:

Size of chambers

The FB & CC are made from 13.5" ID flue steel.

The FB is 19.5" long

The CC is 40" long

using V=πr^2h

the volume of the CC is 5725.55cuIn

the volume of the FB is 2791cuIn

According the formula above, the FB needs to be at least: CCvol X 0.33 for my smoker this is 1889cuIn. That suggests to me that my firebox is plenty big enough for my CC (too big?).

Size of inlet

The formula also tells us how big the air inlet needs to be. Roughly speaking my is a circle which half of the material has been removed. The diameter of that circle is 3.75" which using A=πr^2 gives me 11.0sqIn - which when we consider it's only half filled is then ~5.5sqIn.

If I use the formula then I calculate that I need CCvol x 0.001 which is 5.725sqIn - pretty damn close.

Size of chamber connections

The tube that connects the FB and CC together is 4.5" diameter and 4.5" long. If we calculate the area of the cross section (using A=πr^2) then we get: 15.9sqIn.

If we use the formulate then it should be CCvol x 0.004 which is 22.90sqIn.

So could this be the problem?

Question:

Thanks for sticking with me if you've made it this far!

If it was just that the FB-CC interconnect is too small in diameter, if I were to artificially shorten the length of the CC - thus reducing it's volume - then I should be able to see whether or not this really is the bottleneck, is that right? I could do this with an internal temporary baffle.

To the experience eye, does it seems as thought the symptoms described could be caused by a narrow connection? To the highly untrained eye this seems to be to me an issue with getting clean air to the fire in the first place. Especially considering behaves itself much better when the door is cracked (although a considerable amount of smoke & heat is lost through that exit too - so maybe at explains it)

According to the guide above about 20per cent of the inlet should be above the fire grate. Seeing as my fag-packet calculations show that inlet is slight undersized (I will do a more accurate calculation later) I think that drilling some higher inlet holes might be a fairly unintrusive experiment. Does this sound sensible?

If there are other experiments I could conduct that I am happy to give them a go too. I really don't want to take a grinder this thing until I am at least fairly certain what's going on.

Thanks.

However there is a problem. I don't seem to be able to sustain a fire large or hot enough to get the cooking chamber (CC) up to temperature - at least not without a lot of work (such as burning fine kindling which requires constant replenishing, poking and topping up).

The design is as follows:

So it's not a 'true' reverse flow smoker as the floor plate (2 in diagram) is perforated (more on that later).

The major quirk to the design however is that the Firebox (FB) is separated from CC via a length of flue steel (ID = 4.5" len = 4.5").

First cook:

My first experiment was to use the smoker in the most basic way possible, leaving everything as you see above. I lit a chimney of charcoal, let it get up to heat, put it in the FB and put small oak sticks on the top.

There was thick smoke from the chimney and the wood would smoulder pathetically. I place the coals on the side closest to the CC and under the connecting pipe between the FB and CC. I placed wood I was about to burn on the other side to it was nice and warm when it was to go on the fire.

Second cook:

I did some investigation online and it seems as though the issue might be that the fire was not hot or big enough. So i tried it again but this time with 2 full chimneys - I experience almost exactly the same issue as before.

Experimentation:

I took the opportunity to try a few things and see what was and wasn't working. The first thing I did was experiment with cracking the door of the FB open, this had a good effect. Instead of smouldering the wood would burn with flame. However a lot of heat and smoke was lost though the open door - so the CC didn't really get that much hotter.

I also took the opportunity to remove the internal baffling so the smoke went straight into CC at the side closest the FB and straight out of the chimney. When I did this in-conjunction with the door being cracked I was able to just about get a decent cook (of course only in the area very close to stack - so not big enough for anything other than a small chicken.

Third Cook:

I decided I would dispense with the peculiarity of this design with the perforated floor plate and try and convert it into a normal reverse flow smoker. To do this I used foil tape to seal up all of the joins and the perforations. I pulled the floor plate towards the FB a bit create a gap at the far end of the CC to the smoke to perform it's U-turn.

Rather depressingly at first I was experiencing all of the same issues as before. Thick white smoker, struggling to keep wood burning properly, it just wanted to smoulder.

I then decide to increase the the size of the stack. With a DIY extension:

This had a clear positive impact on the draw speed and seemed to make thing a tiny bit more stable. But not a lot.

I then decide to move the fire from the side closest the CC to the side closest the inlet. And at last I was able to burn wood with a flame with the fire box door close. However the fire is rather unstable - it only likes to burn fine kindling which require topping up and poking frequently and even then from time to time it'd still decide it was going to self extinguish.

Early Prediction:

A this point I am thinking to myself the issue is surely that the fire is not getting enough clean air in to burn hot and constantly enough.

Maths:

So in my research on trying to fix this issue I ran across this post on this forum:

https://www.smokingmeatforums.com/t...eady-to-use-rev5-6-19-15.172425/#post_1264161

Here is how the stats weigh up for my smoker:

Size of chambers

The FB & CC are made from 13.5" ID flue steel.

The FB is 19.5" long

The CC is 40" long

using V=πr^2h

the volume of the CC is 5725.55cuIn

the volume of the FB is 2791cuIn

According the formula above, the FB needs to be at least: CCvol X 0.33 for my smoker this is 1889cuIn. That suggests to me that my firebox is plenty big enough for my CC (too big?).

Size of inlet

The formula also tells us how big the air inlet needs to be. Roughly speaking my is a circle which half of the material has been removed. The diameter of that circle is 3.75" which using A=πr^2 gives me 11.0sqIn - which when we consider it's only half filled is then ~5.5sqIn.

If I use the formula then I calculate that I need CCvol x 0.001 which is 5.725sqIn - pretty damn close.

Size of chamber connections

The tube that connects the FB and CC together is 4.5" diameter and 4.5" long. If we calculate the area of the cross section (using A=πr^2) then we get: 15.9sqIn.

If we use the formulate then it should be CCvol x 0.004 which is 22.90sqIn.

So could this be the problem?

Question:

Thanks for sticking with me if you've made it this far!

If it was just that the FB-CC interconnect is too small in diameter, if I were to artificially shorten the length of the CC - thus reducing it's volume - then I should be able to see whether or not this really is the bottleneck, is that right? I could do this with an internal temporary baffle.

To the experience eye, does it seems as thought the symptoms described could be caused by a narrow connection? To the highly untrained eye this seems to be to me an issue with getting clean air to the fire in the first place. Especially considering behaves itself much better when the door is cracked (although a considerable amount of smoke & heat is lost through that exit too - so maybe at explains it)

According to the guide above about 20per cent of the inlet should be above the fire grate. Seeing as my fag-packet calculations show that inlet is slight undersized (I will do a more accurate calculation later) I think that drilling some higher inlet holes might be a fairly unintrusive experiment. Does this sound sensible?

If there are other experiments I could conduct that I am happy to give them a go too. I really don't want to take a grinder this thing until I am at least fairly certain what's going on.

Thanks.