Anybody ever try Hi-Temp JBWeld for patching a small hole?

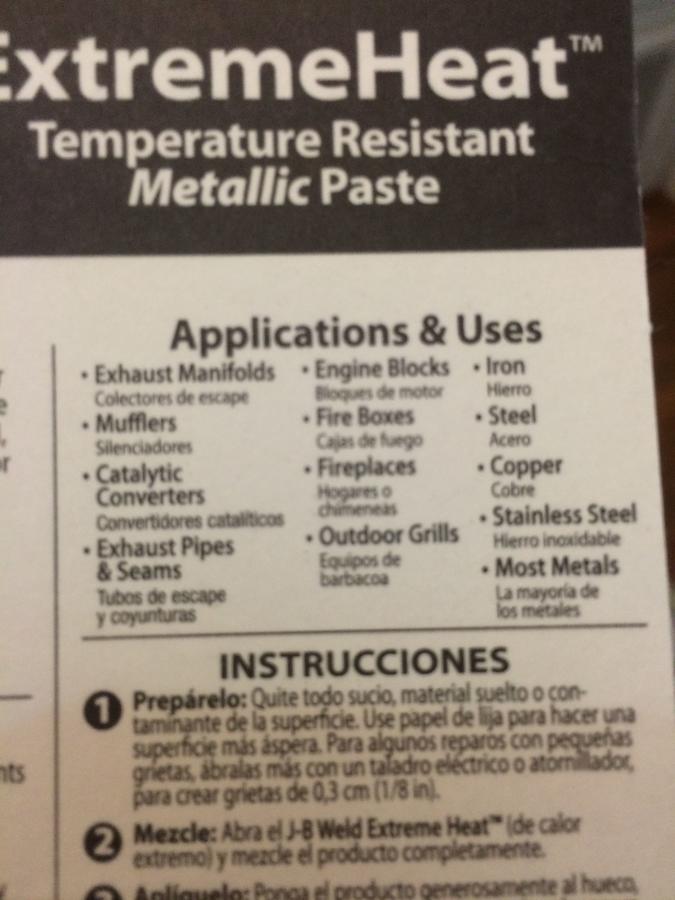

According to the manufacturer it can be used on firebox and/or grills and rated to 2400 degf.

The hole on my unit is "dime-size" and on the grill side (not the firebox) and I don't plan to use that side for charcoal. I am only gonna smoke in this unit. It is a Brinkmann Pitmaster all-steel offset charcoal smoker. So the coals will be far from the welded area, over in the firebox, which should help avoid poisonous gasses.

According to the manufacturer it can be used on firebox and/or grills and rated to 2400 degf.

The hole on my unit is "dime-size" and on the grill side (not the firebox) and I don't plan to use that side for charcoal. I am only gonna smoke in this unit. It is a Brinkmann Pitmaster all-steel offset charcoal smoker. So the coals will be far from the welded area, over in the firebox, which should help avoid poisonous gasses.

Last edited: