Welcome! I have been smoking and cooking meats for at least the past 10 years, I know it's really not that long but considering I am only 27 it's been a good portion of my life. I have always used grills and cheap store bought smokers(think Brinkman stand up) but have ALWAYS envied some of the home brewed smokers I've come across in the past. Problem was up until about two years ago I knew NOTHING about fabrication/welding outside of what I practiced in high school. Fast forward to the present and I feel comfortable with my abilities to accomplish this task, not only that but the opportunity just sort of fell into my lap in just the past few days. Due to the unforeseen demise(aw shucks)of an 80 gallon air compressor I have acquired said tank for this project. Best part was it's FREE!

With that said pictures of the tank are below, including the original plate from the manufacturer. Appears to be in decent shape considering it was manufactured in 1959! Although I was told it has a hole I haven't found any obvious ones yet, however did find a spot which has been patched in the past. I will get better pics once I actually get it into the shop and start working on it. And on that note being able to work on this project in the shop I work at is for sure going to come in handy! I have already been talking to the engineer about getting the program to cut the parts of the smoker with our production plasma cutter, although unsure yet if I will have to pay for those materials of if we may have the material "laying around." On top of all that we also have a sandblasting booth which will definitely come in handy!

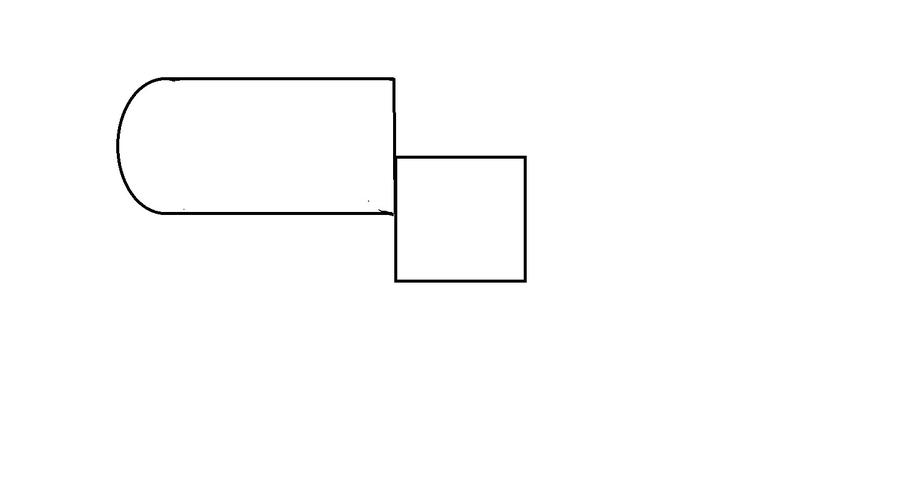

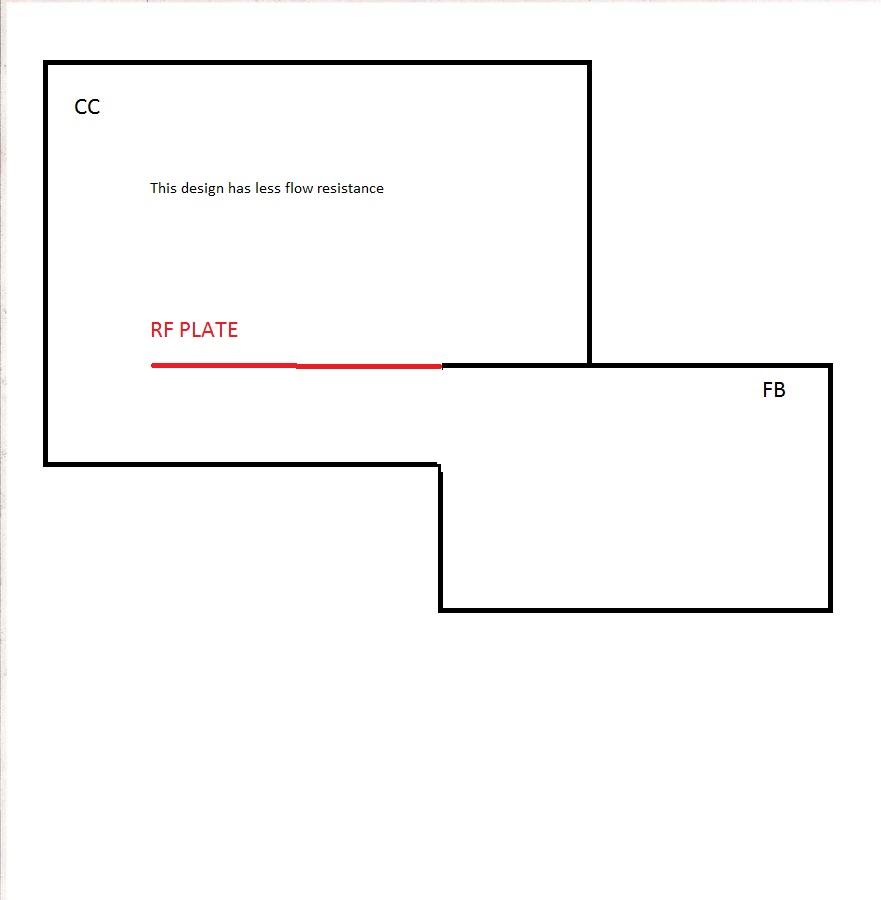

Onto what I've worked out so far. I got some rough OD dimensions(approx 63.25" in circumference, 20" diameter, and 66" length) of the tank and put them into Feldon's Calculator, but I'm curious if I should use the 80 gallon capacity for my calculations or the physical dimensions of the tank? I tried both and there is about a 2,000 cubic in. difference in CC size. Worked out the numbers using the 80 gallon capacity and CC comes out to 18,480 cubic in. Recommended FB size is 6,160 cubic in. the FB I worked out at H-28" W-12" L-20" comes out a little larger at 6,720 cubic in. Intake openings are recommended to be 20.16 cubic in. I worked it out to four openings at 3.675"x1.375". Plan to use a 5" diameter chimney which comes to 17.12 in. to achieve a recommenced 336 cubic in. Where I get lost is the FB to CC opening numbers, I mean I understand what they mean but how do I figure out 53.76 sq in. on the tank itself? Any input on this would be appreciated. My next question is about the RF plate itself. I understand striking it so that the fat collects in the center and eventually flows to a drain, but which to which end? The obvious direction would be towards the FB so aid in the smoke flow into the CC but wont things tend to drain into the FB? Also how much of a drop from end to end over 66" will be needed to flow efficiently? Also I am building the FB out of .25" plate will I need to install an insulating layer around the FB? I live in the Northwest, Vancouver, WA to be exact and temperatures can get cold but not often much below freezing.

Again any and all input will be appreciated as I am going into this project totally blind, but I am looking forward to it quite a bit! I look forward to meeting people within the community and gaining some knowledge along the way.

With that said pictures of the tank are below, including the original plate from the manufacturer. Appears to be in decent shape considering it was manufactured in 1959! Although I was told it has a hole I haven't found any obvious ones yet, however did find a spot which has been patched in the past. I will get better pics once I actually get it into the shop and start working on it. And on that note being able to work on this project in the shop I work at is for sure going to come in handy! I have already been talking to the engineer about getting the program to cut the parts of the smoker with our production plasma cutter, although unsure yet if I will have to pay for those materials of if we may have the material "laying around." On top of all that we also have a sandblasting booth which will definitely come in handy!

Onto what I've worked out so far. I got some rough OD dimensions(approx 63.25" in circumference, 20" diameter, and 66" length) of the tank and put them into Feldon's Calculator, but I'm curious if I should use the 80 gallon capacity for my calculations or the physical dimensions of the tank? I tried both and there is about a 2,000 cubic in. difference in CC size. Worked out the numbers using the 80 gallon capacity and CC comes out to 18,480 cubic in. Recommended FB size is 6,160 cubic in. the FB I worked out at H-28" W-12" L-20" comes out a little larger at 6,720 cubic in. Intake openings are recommended to be 20.16 cubic in. I worked it out to four openings at 3.675"x1.375". Plan to use a 5" diameter chimney which comes to 17.12 in. to achieve a recommenced 336 cubic in. Where I get lost is the FB to CC opening numbers, I mean I understand what they mean but how do I figure out 53.76 sq in. on the tank itself? Any input on this would be appreciated. My next question is about the RF plate itself. I understand striking it so that the fat collects in the center and eventually flows to a drain, but which to which end? The obvious direction would be towards the FB so aid in the smoke flow into the CC but wont things tend to drain into the FB? Also how much of a drop from end to end over 66" will be needed to flow efficiently? Also I am building the FB out of .25" plate will I need to install an insulating layer around the FB? I live in the Northwest, Vancouver, WA to be exact and temperatures can get cold but not often much below freezing.

Again any and all input will be appreciated as I am going into this project totally blind, but I am looking forward to it quite a bit! I look forward to meeting people within the community and gaining some knowledge along the way.