- Oct 22, 2014

- 39

- 10

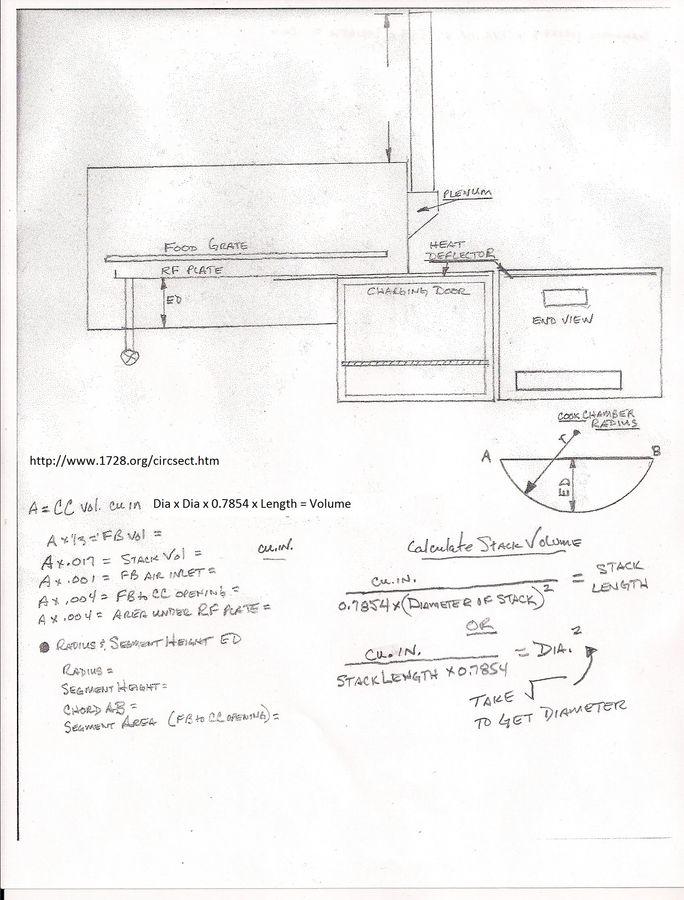

Hello, I'm new to the forum, but have helped roast pigs for a few years on borrowed and rented roasters. I love the idea, process, and challenge of smoking and recently bought a stalled project from someone else. Its a 275 gallon oil tank with a good deal of the metal work already done. The builder put a thin water or ash lower tray with a slightly elevated charcoal tray above it, with the pan being about 16" from the bottom of the tank. About 7.5" above the lower tray is the primary cooking grate, which makes it approximately 24" from the bottom of the tank. The builder said he planned to put a smoker box "off of the back". He seemed like a great guy, but I don't know how much he knew about building a smoker. I want to add a firebox on the right side as you are facing the grates and hope to make it out of 1/4" metal. I plan to add a piece of 1/4" metal below the water / ash pan and cut the pan down to allow smoke to flow around the left side. I believe this is best as it will allow me to open the access door above the firebox to add water to the pan and remove it when done for easy cleaning. I have looked at the Feldon calculator, but am having difficulty deciding on the below listed questions. Thanks in advance and I will update photos as I work to finish this during the winter months. I anticipate a variety of opinions and hope the discussion will help me decide what is best for my purposes. I do plan to add wheels and a hitch assembly at some point.

1. What size should my firebox be?

2. What size should my opening between the firebox and the tank be?

3. How much area should I allow for flow between the water pan / baffle and the cooking area?

4. What size exhaust opening should I use?

1. What size should my firebox be?

2. What size should my opening between the firebox and the tank be?

3. How much area should I allow for flow between the water pan / baffle and the cooking area?

4. What size exhaust opening should I use?

Last edited: