As I often read before ordering, GOSM smokers are not packed well for shipment. Heavy cast-iron boxed parts bouncing around loosly inside the smoker body bent the racks up/down and generally out of place. I tried straightening them with pliers, but that was too much of a good thing - some of the welds broke. I ended up taking the racks out and used a MIG welder to strengthen every joint:

Took the above photo before painting, but I subsequently covered the racks with Dupli-Color Engine Enamel with Ceramic (silver) I found at Auto Zone (rated to 500 deg F) to prevent rust.

I then put the racks back in and added center supports to strengthen both the shelves and the sheet metal sides (NM/SE cable, One Hole Midget Straps, 1/4"):

These were secured with some nice bolts I found at Lowes (10-24 x 1/2", Fan Blade Screws, Ceiling, Bronze):

I then added the temp probe port as suggested by travcoman45 by cutting a hole through the smoker body (yes, it hurt to drill a new smoker ;-):

and inserted the 1/2" UF Water Tight Connector fitting:

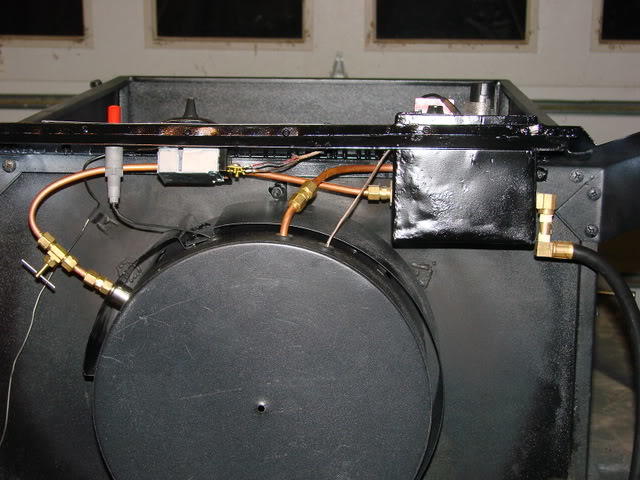

From there I moved on to adding a thermostat controlled gas valve, but that's for a later post.

Good smoking,

Jon

Took the above photo before painting, but I subsequently covered the racks with Dupli-Color Engine Enamel with Ceramic (silver) I found at Auto Zone (rated to 500 deg F) to prevent rust.

I then put the racks back in and added center supports to strengthen both the shelves and the sheet metal sides (NM/SE cable, One Hole Midget Straps, 1/4"):

These were secured with some nice bolts I found at Lowes (10-24 x 1/2", Fan Blade Screws, Ceiling, Bronze):

I then added the temp probe port as suggested by travcoman45 by cutting a hole through the smoker body (yes, it hurt to drill a new smoker ;-):

and inserted the 1/2" UF Water Tight Connector fitting:

From there I moved on to adding a thermostat controlled gas valve, but that's for a later post.

Good smoking,

Jon

Last edited: