Just joined recently as I have been digging through the forum trying to learn as much as possible. To get started, my inspiration for this build is my brothers wedding. Myself and the third brother were tasked with coming up of a way to feed roughly 50 people with meat. So far our parents have got two pigs growing, one of which will be used for the wedding.

Two days ago I didn't know the difference between a side box and a vertical, but I am trying to figure it out. If I mistakenly call something by the wrong name please let me know.

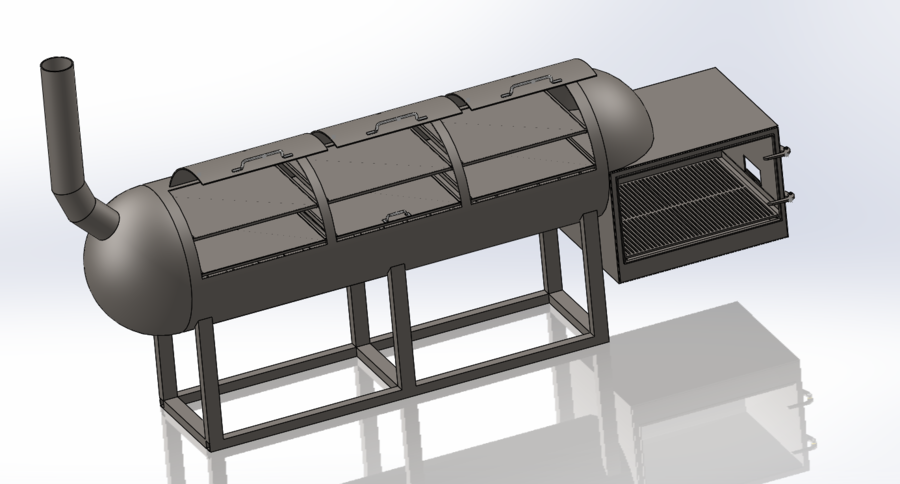

On to the design, I have been looking around at a bunch of the builds and the one that really stood out to me was SmokedStanley's he started last summer. (Seen Below) I definitely don't need it to be as big as his, but the overall shape and layout is what I was thinking to follow.

http://www.smokingmeatforums.com/t/247284/this-years-build-thread

One thing I did want to ask about was if the same wide rectangle design could be done as a vertical without too many issues? I am just reading up on the differences between the horizontals and verticals, but as of right now it looks like the three big things are temperature control, moisture, and time between fuelings.

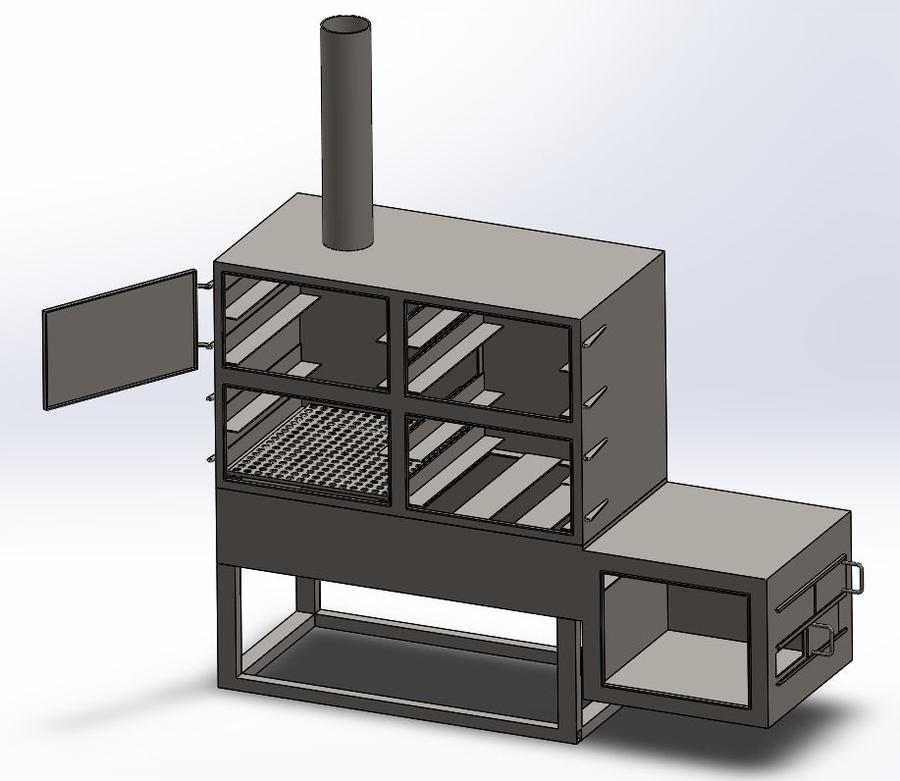

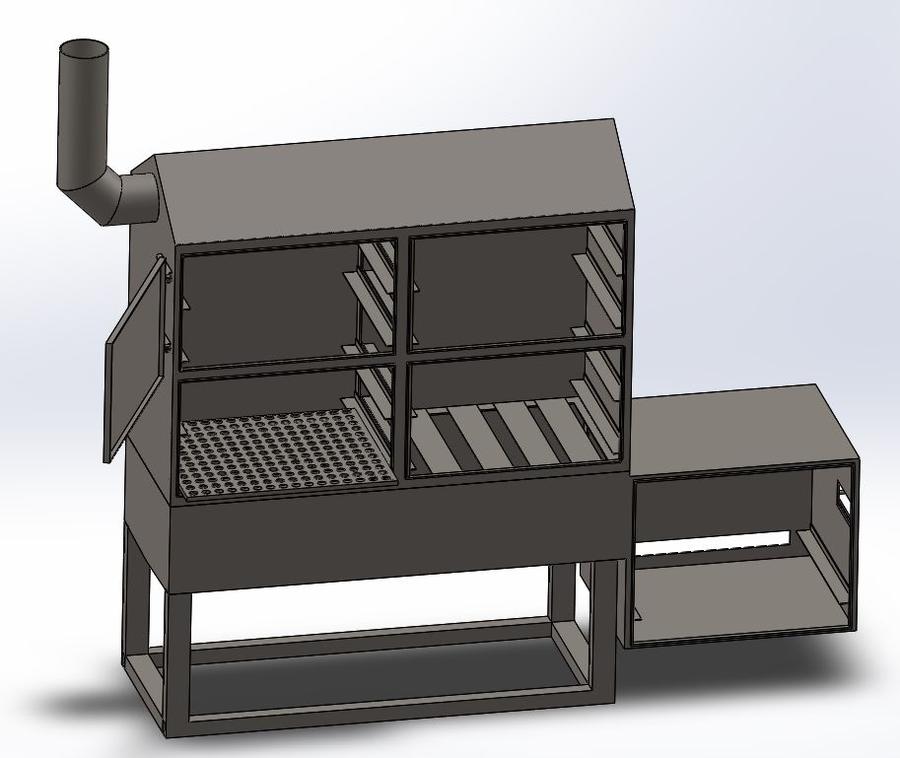

As for specifics, I have been using Feldon's calculator for the sizing of smoker and have been playing around with designs in Solidworks. Cooking chmaber size is 60" x 36" x 30". Firebox dimensions are 30" x 30" x 24".

The firebox on this one is all 1/4" A36 and the rest of the body is 3/16". My current plan would be get pieces plasma or torch cut out and then mig weld it up at my parents house. Ideally I would like be able to put it on some large casters or the rubber wheels that some smokers use. Really want to stay away from getting heavy enough that it needs a tow-able trailer.

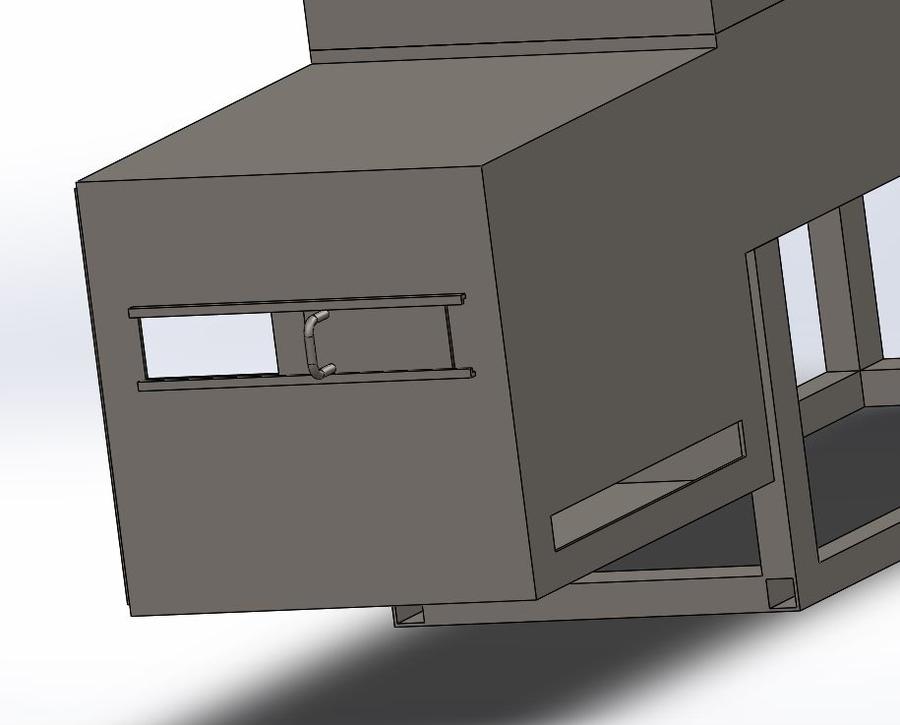

Still playing around with the firebox air inlets and may try to incorporate them into the door. The transfer hole from the firebox to the cooking area is about 28 x 8". Right now I was just planning on using some plates laid out in the bottom of the cooking area to regulate the heat on the right side so the left got enough. Are there better ways to do this and still be adjustable?

Rack sizes would be 26.75" x 28" and that would leave 6.5" of vertical clearance for all of them. Could also leave one out if I ever needed extra height.

If anybody has input of any type please let me know. In the meantime I will keep playing around with the design and keep reading the forums.

Two days ago I didn't know the difference between a side box and a vertical, but I am trying to figure it out. If I mistakenly call something by the wrong name please let me know.

On to the design, I have been looking around at a bunch of the builds and the one that really stood out to me was SmokedStanley's he started last summer. (Seen Below) I definitely don't need it to be as big as his, but the overall shape and layout is what I was thinking to follow.

http://www.smokingmeatforums.com/t/247284/this-years-build-thread

One thing I did want to ask about was if the same wide rectangle design could be done as a vertical without too many issues? I am just reading up on the differences between the horizontals and verticals, but as of right now it looks like the three big things are temperature control, moisture, and time between fuelings.

As for specifics, I have been using Feldon's calculator for the sizing of smoker and have been playing around with designs in Solidworks. Cooking chmaber size is 60" x 36" x 30". Firebox dimensions are 30" x 30" x 24".

The firebox on this one is all 1/4" A36 and the rest of the body is 3/16". My current plan would be get pieces plasma or torch cut out and then mig weld it up at my parents house. Ideally I would like be able to put it on some large casters or the rubber wheels that some smokers use. Really want to stay away from getting heavy enough that it needs a tow-able trailer.

Still playing around with the firebox air inlets and may try to incorporate them into the door. The transfer hole from the firebox to the cooking area is about 28 x 8". Right now I was just planning on using some plates laid out in the bottom of the cooking area to regulate the heat on the right side so the left got enough. Are there better ways to do this and still be adjustable?

Rack sizes would be 26.75" x 28" and that would leave 6.5" of vertical clearance for all of them. Could also leave one out if I ever needed extra height.

If anybody has input of any type please let me know. In the meantime I will keep playing around with the design and keep reading the forums.

Last edited: