- Dec 10, 2016

- 6

- 10

Well my old grill is finally about dead. Its over 10 years old, doors have fallen off and the "Stainless Steel" is starting to rust.

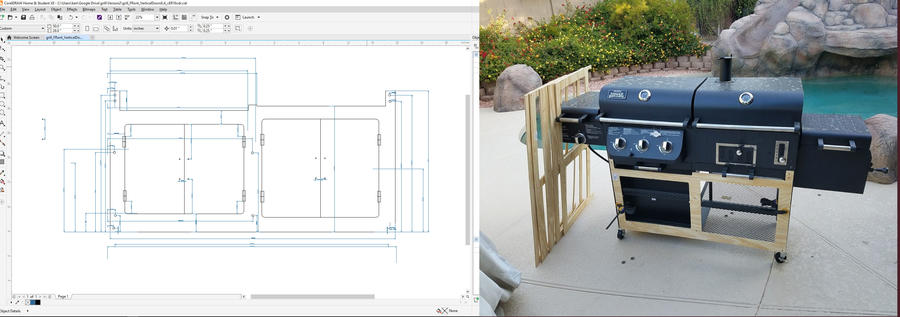

The old one also has multiple doors and even a cubby on the side that you can not see in this picture. I have been wanting to try to smoke and grill with charcoal and gas and I did not want to break the bank as well. Walking around a store I found this "Smoke Hollow" that has a Propane, Charcoal grills as well as an offset smoker but it only had open shelves which would have been a deal breaker except for the fact that I needed a project.

After getting it home, spending 4-5 hours to assemble, I smoked a brisket and it seemed to work pretty well. Didn't smoke it long enough and found out that you need quite a bit of charcoal to keep a smoker going 10+ hours, plus a lot of other things :). Even bought a nice wireless thermometer and supplies from my local store here.

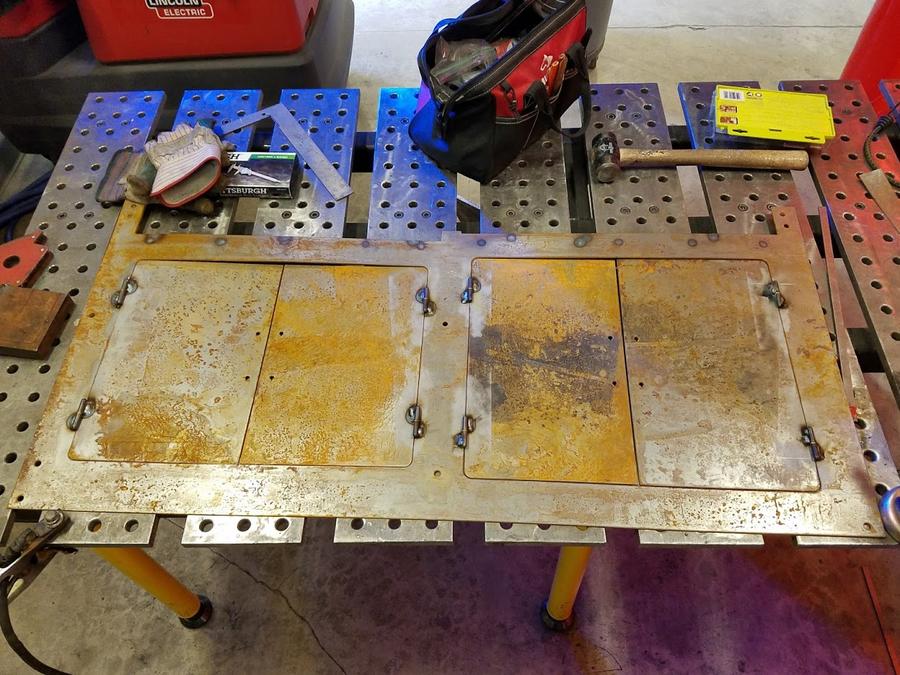

However, the missing doors and a place to keep stuff "kind of clean" is a real pain. I have a pile of pans and other stuff that I kept in the old grill. So I have decided to enclose the open shelves with two sets of doors, and backs, as well as learn how to create drawings I can use on the ShopBot wood CNC machine(Verify my design with cheap wood), port those drawings to work with the Water jet I can use to cut it out 14 Gauge sheet steel as well as learn how to use a MIG welder better that what I can do now, as well as powder coating it.

I am currently working on my initial design and will try to cut it out tonight.

The old one also has multiple doors and even a cubby on the side that you can not see in this picture. I have been wanting to try to smoke and grill with charcoal and gas and I did not want to break the bank as well. Walking around a store I found this "Smoke Hollow" that has a Propane, Charcoal grills as well as an offset smoker but it only had open shelves which would have been a deal breaker except for the fact that I needed a project.

After getting it home, spending 4-5 hours to assemble, I smoked a brisket and it seemed to work pretty well. Didn't smoke it long enough and found out that you need quite a bit of charcoal to keep a smoker going 10+ hours, plus a lot of other things :). Even bought a nice wireless thermometer and supplies from my local store here.

However, the missing doors and a place to keep stuff "kind of clean" is a real pain. I have a pile of pans and other stuff that I kept in the old grill. So I have decided to enclose the open shelves with two sets of doors, and backs, as well as learn how to create drawings I can use on the ShopBot wood CNC machine(Verify my design with cheap wood), port those drawings to work with the Water jet I can use to cut it out 14 Gauge sheet steel as well as learn how to use a MIG welder better that what I can do now, as well as powder coating it.

I am currently working on my initial design and will try to cut it out tonight.