- Aug 27, 2016

- 1,334

- 462

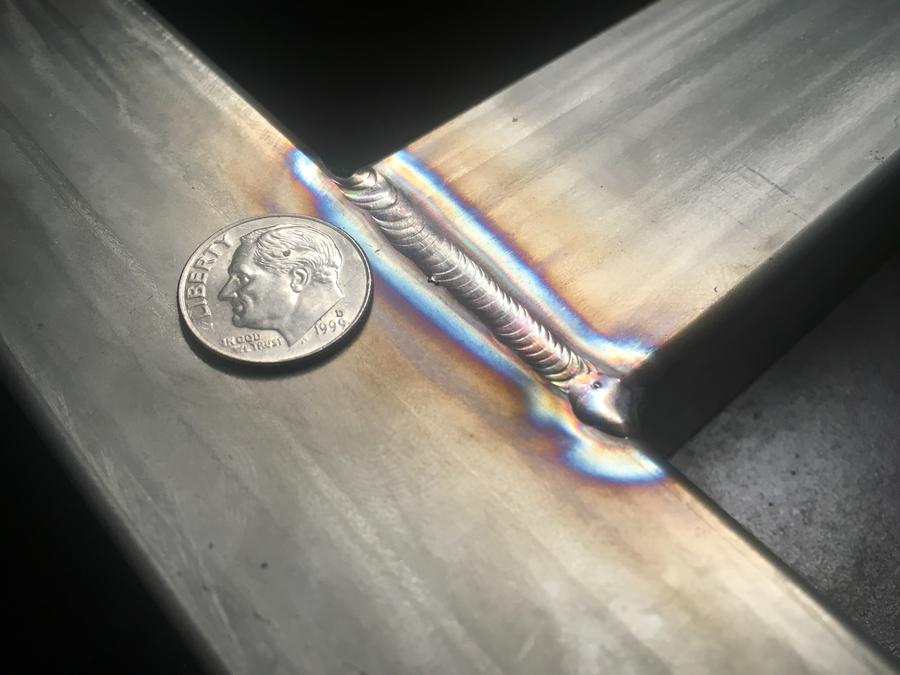

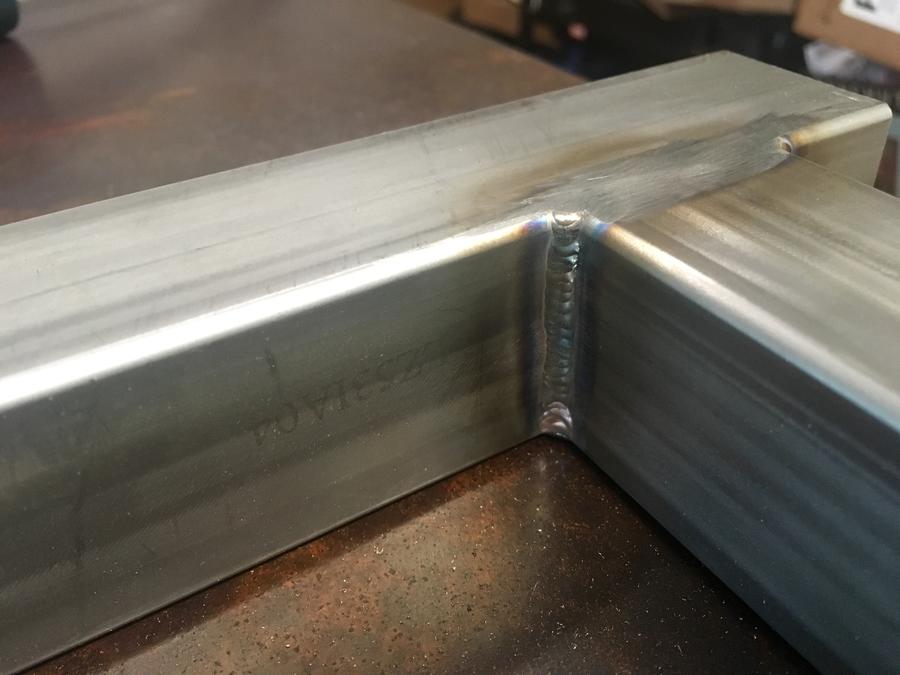

Hello ladies and gentlemen. I'm on my way build in this smoker that I started in June but work a lot of hours and can't work on it as much as I'd like to. This smoker will be all stainless steel. It's 16 gauge 1.5" square tube frame and 11 gauge walls. Fire box will be offset and its 1/4" and fire bricked all inside besides the lid becuase that might be 1/2" for cooking surface,Got the plate for 1.20$ per pound and they were water jet cut Rem pieces. I have 5 pieces and just need a lid. The 4x10 1/8" sheet I got for 1$ per pound, so I'm doing pretty good so far, hoping to have a smoker that will last the rest of my life for 1000$, fingers crossed lol. This is my first smoker build and have never ran a stick burner before so I'm pretty green. I have a question on what size exuast and intake to run and also how low should my exuast be?