What is the best calculator to use for a reverse flow build

- Thread starter lovelife

- Start date

-

Some of the links on this forum allow SMF, at no cost to you, to earn a small commission when you click through and make a purchase. Let me know if you have any questions about this.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

SMF is reader-supported. When you buy through links on our site, we may earn an affiliate commission.

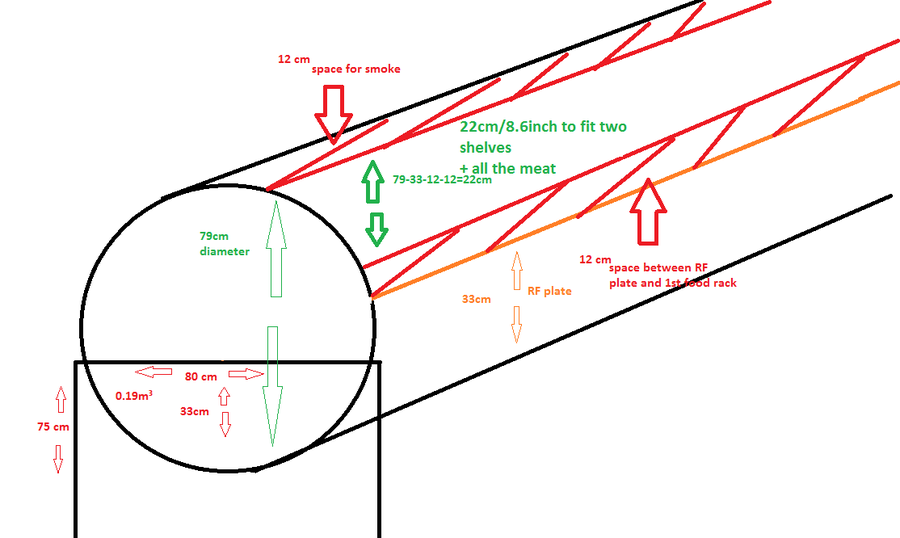

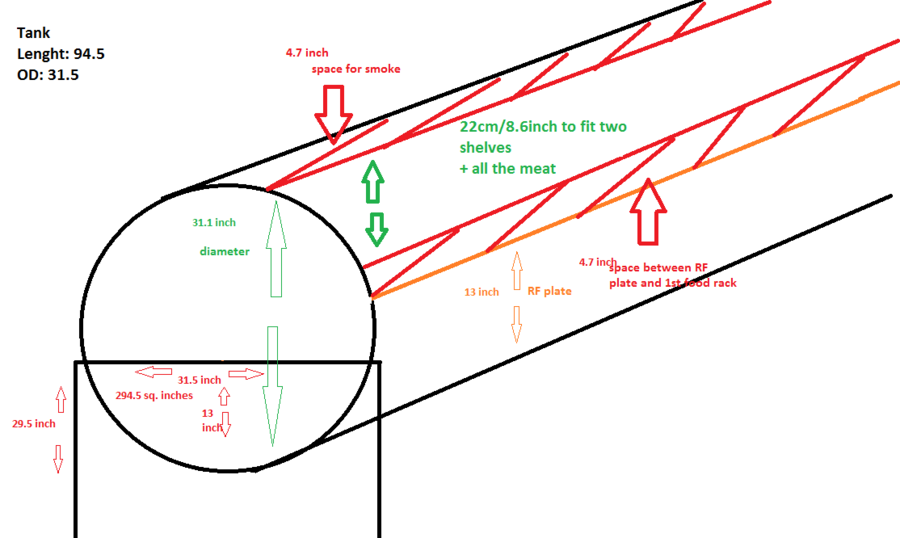

19cm doesn't make sense since the opening from FB to CC will be around 33cm high.

I made this drawing, and I'm not too happy that I only have 22cm / 8.6 inches to fit two racks and all my meat.

Am I doing something wrong or is this the consequence of having a somewhat skinny tank (31 inch diameter).

I made this drawing, and I'm not too happy that I only have 22cm / 8.6 inches to fit two racks and all my meat.

Am I doing something wrong or is this the consequence of having a somewhat skinny tank (31 inch diameter).

Last edited:

Thank you.... That makes life easier for both of us... If you go "OVERTHINKING" this smoker design.... what if I do this.... or that.... thinking you will improve on the smoker.... Build it this way first.... then build another smoker to compare them and how they operate... This design is not perfect by any stretch of the imagination but it works darn good..... Either one of the exhaust stack installations will work very well.... Notice how they are installed in the picture... The FB inlets are opposite the CC.... that works... Insert the FB past the weld seam on the tank... The weld seam "usually" has a backing plate on the inside... Life will be easier if you do that... the RF plate will be a rectangle and you will save on fit-up... I recommend skip welding in angle iron for the RF plate to sit on... the plate can rest on top of the FB or butt up to in.... Weld a small angle on the end of the RF plate to stop grease from dripping into the CC and install a drain on the RF plate that extends through the CC wall into a bucket... drill a hole in the CC wall for the drain to fit... it does not have to be air tight but close fit for the drain pipe will do.. drill the holes for the drain in the RF plate and CC wall, install the drain pipe and weld to the RF plate and install (thread on) a ball valve on the outside of the CC tank... it should be hand tight.. One thing that works is... break the RF plate so there is a "Vee" down the center... a drop of 3/8" - 1/2" is plenty for the grease to follow...

94.5 inches long

OD 31.5 inches

Build and weld up the FB before you cut the doors.... welding up the FB first, "may" save on the tank warping and screwing up the door fitment... weld up the FB using good welding practices...

31 x 31 x .7854 x 88 = 66,400 cu. in. (31 is the I.D.) (88 is the compensated length for the bulbous end) close enough....

66,400 x 0.004 = 266 sq. in. for FB/CC opening etc....

66,400 x 0.001 = 66 sq. in. FB air inlet openings...

66,400 x 0.022 = 1,460 cu. in. for the exhaust stack (above the CC)

1460 / 0.7854 x 7 x 7 = 38" length above the CC and use a 7" ID exhaust tube...

Circle calculator...... open it....

click on RADIUS - SEGMENT HEIGHT.....

R= 15.5" guess at the segment height until you come up with a number close to 266 sq. in. from the above numbers...

12" segment height gives a segment area of 270 sq. in.

Chord AB is the width of your RF plate at 30.2 inches....

Firebox air inlets.... upper inlet ~10 sq. inches... lower inlet ~ 50 sq. in. below the fire grate... ~6" under the fire grate for ash collection area....

The tutorial has pictures and written description of everything else for you to make a great RF smoker...

I think that covers it... Good luck.... May I recommend you only have ONE thread to cover all the aspects of this build and ALL related topics so folks can follow along and not have to skip back and forth....

I really appreciate you Dave.

It's 4am, I woke up, read your comment and am sitting behind my computer now. I am going to summarize everything and put it on paper.

My numbers were somewhat close except for the smokestack, I messed up somewhere. The difference in numbers because of the 88 inch length tank versus the 91.5 inch length tank.

I am so much more relaxed now that I can provide my guy with a plan. He has been a welder for 35+ years so he should be pretty good.

Maybe an idea to change the title to Reverse Flow Smoker 300 gallon build? This way I can also post pictures and keep updating this thread.

It's 4am, I woke up, read your comment and am sitting behind my computer now. I am going to summarize everything and put it on paper.

My numbers were somewhat close except for the smokestack, I messed up somewhere. The difference in numbers because of the 88 inch length tank versus the 91.5 inch length tank.

I am so much more relaxed now that I can provide my guy with a plan. He has been a welder for 35+ years so he should be pretty good.

Maybe an idea to change the title to Reverse Flow Smoker 300 gallon build? This way I can also post pictures and keep updating this thread.

1) I checked smokerbuilder.com their calculator and everything is pretty close except for the FB to CC opening and Smoke stack.

Smokerbuilder recommends a 193 sq inch opening FB to CC, while you (Dave) recommends a 271 sq inch opening (I made a mistake with my tank length and adjusted the calculations).

Anyway, seems like a huge difference. They say bigger than what they recommend is just using more fuel unnecessary.

They also recommend a different dimension of smokestack. A 32 inch tall smokestack instead of 38.7 inch stack.

I know that you, Dave have a lot of experience and I feel very confident following your calculation and advice. I am just super curious where this difference is coming from. I mean it's not a small difference and it seems like people are happy with their smokers on both sides.

I also have another question. During winter time it gets around 32F here (some days it freezes and some days its just above 32F). I would like to insulate my FB since wood is somewhat expensive here. I was planning on using 0.3 inch steel for my FB. Steel is not cheap (here). My questions:

2) Could I split the 0.3 inch into two? And use 0.15 inch steel both for the inside and outside of the FB with an inch of ceramic wool in the middle? Would 2 inch of ceramic wool be better? If I would have to use a thicker steel, then would I use the thicker steel for the inside or the outside of the FB (I have seen both online)?

3) Dave, check your inbox. I would like to show send you some European goodies to show you my appreciation.

Smokerbuilder recommends a 193 sq inch opening FB to CC, while you (Dave) recommends a 271 sq inch opening (I made a mistake with my tank length and adjusted the calculations).

Anyway, seems like a huge difference. They say bigger than what they recommend is just using more fuel unnecessary.

They also recommend a different dimension of smokestack. A 32 inch tall smokestack instead of 38.7 inch stack.

I know that you, Dave have a lot of experience and I feel very confident following your calculation and advice. I am just super curious where this difference is coming from. I mean it's not a small difference and it seems like people are happy with their smokers on both sides.

I also have another question. During winter time it gets around 32F here (some days it freezes and some days its just above 32F). I would like to insulate my FB since wood is somewhat expensive here. I was planning on using 0.3 inch steel for my FB. Steel is not cheap (here). My questions:

2) Could I split the 0.3 inch into two? And use 0.15 inch steel both for the inside and outside of the FB with an inch of ceramic wool in the middle? Would 2 inch of ceramic wool be better? If I would have to use a thicker steel, then would I use the thicker steel for the inside or the outside of the FB (I have seen both online)?

3) Dave, check your inbox. I would like to show send you some European goodies to show you my appreciation.

Use my numbers.... you will not be sorry..... the oversized FB/CC opening is to reduce friction in the RF smoker... The builder that says, "Larger opening burns more fuel"..... He's trying to justify his design with a comment that cannot be supported with technical data....

I have letters from folks that had smokers with "small" FB/CC openings that state, "When I changed my smoker to your suggestions, my fuel consumption was cut in half and the range of temperatures attainable were increased by 200 degrees"..... "Temperatures dropped significantly in my FB"....

For the FB, use 0.25" - 0.3" for the inside layer of steel... it will last a very long time and not burn out.... layer of insulation... then thin sheet metal for the protective layer...

http://www.smokingmeatforums.com/t/137442/and-the-mods-continue-for-my-rf-trailer-pit

http://www.smokingmeatforums.com/t/137382/dual-rf-smokers-on-trailer-my-first-adventure

I have letters from folks that had smokers with "small" FB/CC openings that state, "When I changed my smoker to your suggestions, my fuel consumption was cut in half and the range of temperatures attainable were increased by 200 degrees"..... "Temperatures dropped significantly in my FB"....

For the FB, use 0.25" - 0.3" for the inside layer of steel... it will last a very long time and not burn out.... layer of insulation... then thin sheet metal for the protective layer...

http://www.smokingmeatforums.com/t/137442/and-the-mods-continue-for-my-rf-trailer-pit

http://www.smokingmeatforums.com/t/137382/dual-rf-smokers-on-trailer-my-first-adventure

Totally have a good feeling following your numbers Dave.

We cut the doors out and the FB to CC opening. Working on getting rid of most of the rust in the picture.

Unfortunately we measured and made the cut in the tank before i decided to insulate my FB. My insulation will be 25mm thick, the outer layer of steel 2mm. So that would mean I will have to cut another 27mm/1 inch higher in the tank, correct?

Also have a question on how to measure the FB opening cut. Is it as easy as putting the FB in place against the tank, and then from the inside I just draw the half moon onto the back of the FB?

We cut the doors out and the FB to CC opening. Working on getting rid of most of the rust in the picture.

Unfortunately we measured and made the cut in the tank before i decided to insulate my FB. My insulation will be 25mm thick, the outer layer of steel 2mm. So that would mean I will have to cut another 27mm/1 inch higher in the tank, correct?

Also have a question on how to measure the FB opening cut. Is it as easy as putting the FB in place against the tank, and then from the inside I just draw the half moon onto the back of the FB?

Yes on the FB opening cut....

About insulating.. Insulate after the FB is welded up to the CC... Don't insulate where the FB is inside the CC..

About insulating.. Insulate after the FB is welded up to the CC... Don't insulate where the FB is inside the CC..

Will post some pictures soon.

I have a question about the exhaust stack. My father in law can get a pipe that has a Diamante of 5 or 5.5 inch instead of the 7 inches I needed. Would this be too small? Or can I just compensate it by making the stack taller?

I have a question about the exhaust stack. My father in law can get a pipe that has a Diamante of 5 or 5.5 inch instead of the 7 inches I needed. Would this be too small? Or can I just compensate it by making the stack taller?

Use 2 each 5" stacks.... in place of the one 7" stack same thing.... 5" = 19.6 sq. inches... 7" = 38.5 square inches...

I lost money to learn the product of the squares!

Use 2 each 5" stacks.... in place of the one 7" stack same thing.... 5" = 19.6 sq. inches... 7" = 38.5 square inches...

I had to wait for the steel to arrive. 8mm steel for the FB. 6mm for the RF plate. And have 2mm steel ready to be cut to insulate the FB. Some pictures.

Will continue to update this thread.

Will continue to update this thread.

aussiebazza

Smoke Blower

Thanks!

Another question about the exhaust stack. It's going into the tank straight through the roof. How low does the stack need to go into the tank? As low as the height of the 1st food shelve? In between shelve 1 and 2?

And then about the food shelves, how thick does the stainless steel shelves need to be? Too thin might not be sturdy enough?

Another question about the exhaust stack. It's going into the tank straight through the roof. How low does the stack need to go into the tank? As low as the height of the 1st food shelve? In between shelve 1 and 2?

And then about the food shelves, how thick does the stainless steel shelves need to be? Too thin might not be sturdy enough?

Some folks install as noted.... it's up to you.... Imagine the smoke flow and adjust accordingly....

SmokingMeatForums.com is reader supported and as an Amazon Associate, we may earn commissions from qualifying purchases.

Similar threads

- Replies

- 5

- Views

- 2K

- Replies

- 29

- Views

- 3K

- Replies

- 20

- Views

- 4K

- Replies

- 49

- Views

- 5K

- Replies

- 9

- Views

- 2K

Hot Threads

-

PRO 100 SPARES

- Started by sawhorseray

- Replies: 29

- Pork

-

Featured Plate Ribs Tonight

- Started by schlotz

- Replies: 28

- Blowing Smoke Around the Smoker.

-

What do if yiy have too many peaches??? Make dessert of course!

- Started by 02ebz06

- Replies: 23

- General Discussion

-

Trying some new BBQ sauces with some heat (I hope)

- Started by sandyut

- Replies: 22

- Blowing Smoke Around the Smoker.