Hello SMF!

A couple mates and I have been BBQing on a simple bullet smoker that we went 3rds in a few years back and have really gotten hooked. So much so that we've decided to take the next step (well... leap) and build a smoker of our own.

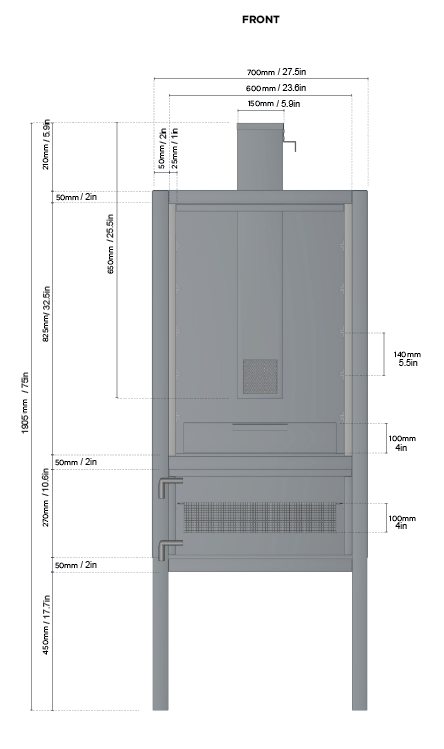

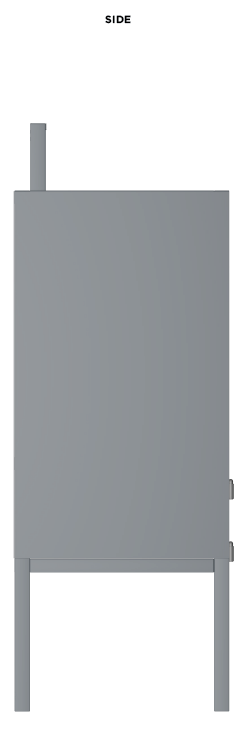

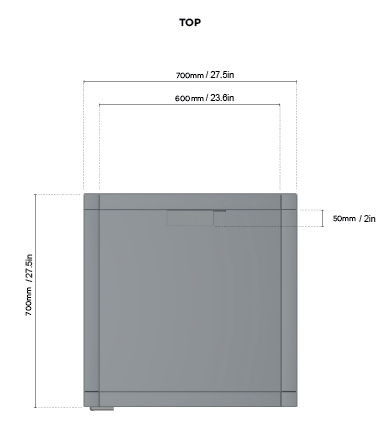

Being based in Australia it's hard to go see a smoker of this type in the flesh, but after looking at many build threads and pit maker websites we drew up the following designs.

The measurements are in millimeters and inches. Happy days!

I would appreciate any feedback from you more seasoned BBQers and builders on our design and I'm sure I'll have a lot of questions along the way.

For a start, we are planning on putting in 2x 50mm (2inch) gate valves for air intakes. What is the best position for them? Do we need to have 2?

What gage steel should we use for the inner skin and outer skin?

I had a friend look over the plan and suggest we line the top of the fire box with heat resistant ceramic tiles (like a pizza oven) to act as a dampener so the steel plate above the fire box can be thinner. Sounded like a good idea. Is it?

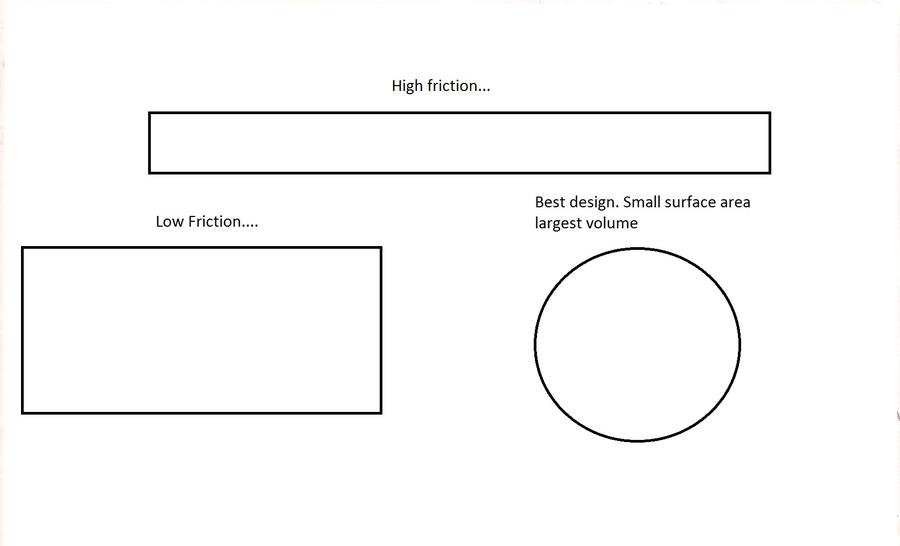

I've looked at BBQ ratios but can't find any rules for this type of smoker, do horizontal BBQ ratios still apply?

Is the position of the flue intake correct? Is the flue big enough?

Are the channels 25mm wide x 600mm long (1inch wide x 26.3inches) big enough for the reverse flow channels?

Ok that's probably enough questions for now!

A couple mates and I have been BBQing on a simple bullet smoker that we went 3rds in a few years back and have really gotten hooked. So much so that we've decided to take the next step (well... leap) and build a smoker of our own.

Being based in Australia it's hard to go see a smoker of this type in the flesh, but after looking at many build threads and pit maker websites we drew up the following designs.

The measurements are in millimeters and inches. Happy days!

I would appreciate any feedback from you more seasoned BBQers and builders on our design and I'm sure I'll have a lot of questions along the way.

For a start, we are planning on putting in 2x 50mm (2inch) gate valves for air intakes. What is the best position for them? Do we need to have 2?

What gage steel should we use for the inner skin and outer skin?

I had a friend look over the plan and suggest we line the top of the fire box with heat resistant ceramic tiles (like a pizza oven) to act as a dampener so the steel plate above the fire box can be thinner. Sounded like a good idea. Is it?

I've looked at BBQ ratios but can't find any rules for this type of smoker, do horizontal BBQ ratios still apply?

Is the position of the flue intake correct? Is the flue big enough?

Are the channels 25mm wide x 600mm long (1inch wide x 26.3inches) big enough for the reverse flow channels?

Ok that's probably enough questions for now!

Last edited: