So, the events are getting bigger, the days can't be stretched any more than they are, just pulled off -another- 4 butt batch out of the BTLE, and tired of watching all these guys are building all these wonderful smokers without DOing anything about it.

So!

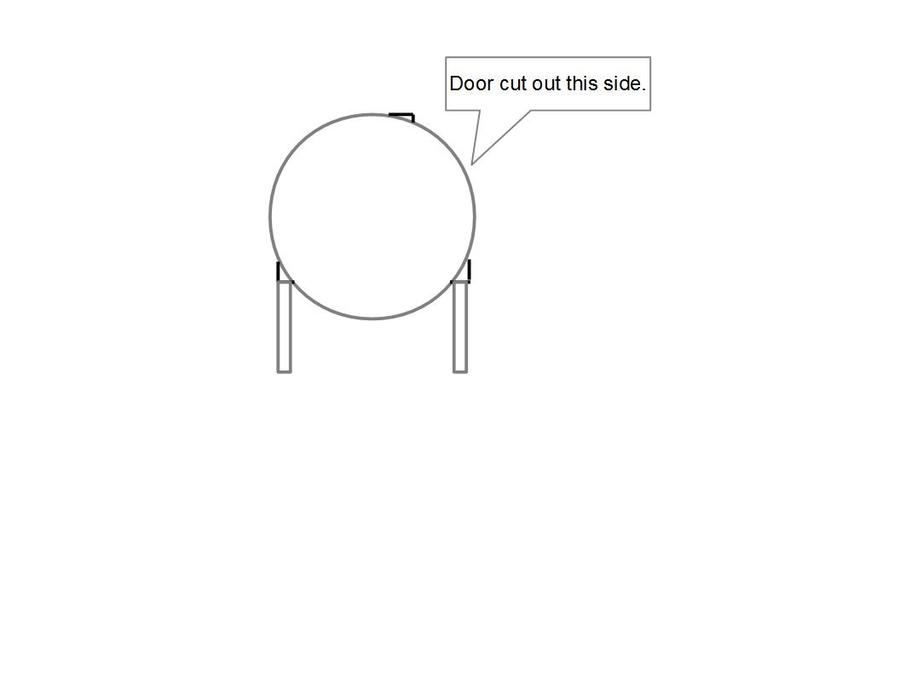

Got a tank from Southern States, the Lincoln tombstone went on sale at HD (it's been a while since I made sparks but I expect I can still lay down a fair bead), a buddy says he has a boat trailer he would let go just for a pork party after the smoke clears -- it seems the stars are aligning and it's Time To Build.

First question:

Southern States says the tank is a "72 gallon". From the dimensions (outside 24" x 48") it is roughly 100 gals.

Allowing for tank wall thickness and some slop for the (not so) curved ends I get a gallon capacity of about 84 gals.

Allowing for an 85% fill factor, seems like that's where the 72 gal. number comes from?

Nothing against my friends at SS but the "I dunno, we call it a 72 wasn't particularly precise.

Glenn.

Pictures here if I can get that to work...

So!

Got a tank from Southern States, the Lincoln tombstone went on sale at HD (it's been a while since I made sparks but I expect I can still lay down a fair bead), a buddy says he has a boat trailer he would let go just for a pork party after the smoke clears -- it seems the stars are aligning and it's Time To Build.

First question:

Southern States says the tank is a "72 gallon". From the dimensions (outside 24" x 48") it is roughly 100 gals.

Allowing for tank wall thickness and some slop for the (not so) curved ends I get a gallon capacity of about 84 gals.

Allowing for an 85% fill factor, seems like that's where the 72 gal. number comes from?

Nothing against my friends at SS but the "I dunno, we call it a 72 wasn't particularly precise.

Glenn.

Pictures here if I can get that to work...