Hi all

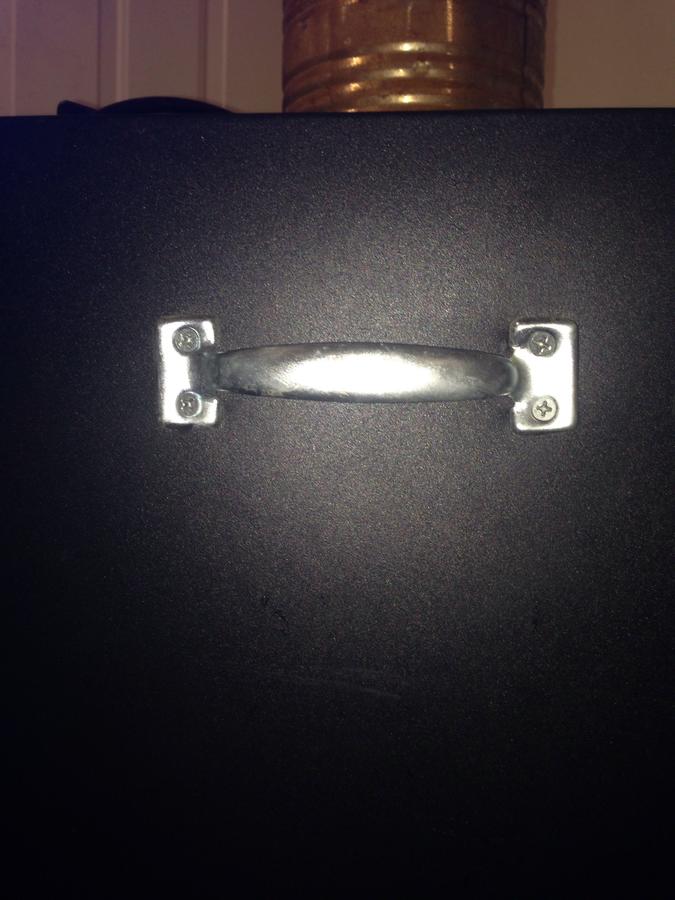

I just picked up a MES 30. (the black one without glass in door) I think this thing could sure use some handles for moving around. Anybody have any suggestions or recommendations for a nice set of hinge type handles? . I assume I'll have to pop rivet them on.

Thanks

I just picked up a MES 30. (the black one without glass in door) I think this thing could sure use some handles for moving around. Anybody have any suggestions or recommendations for a nice set of hinge type handles? . I assume I'll have to pop rivet them on.

Thanks