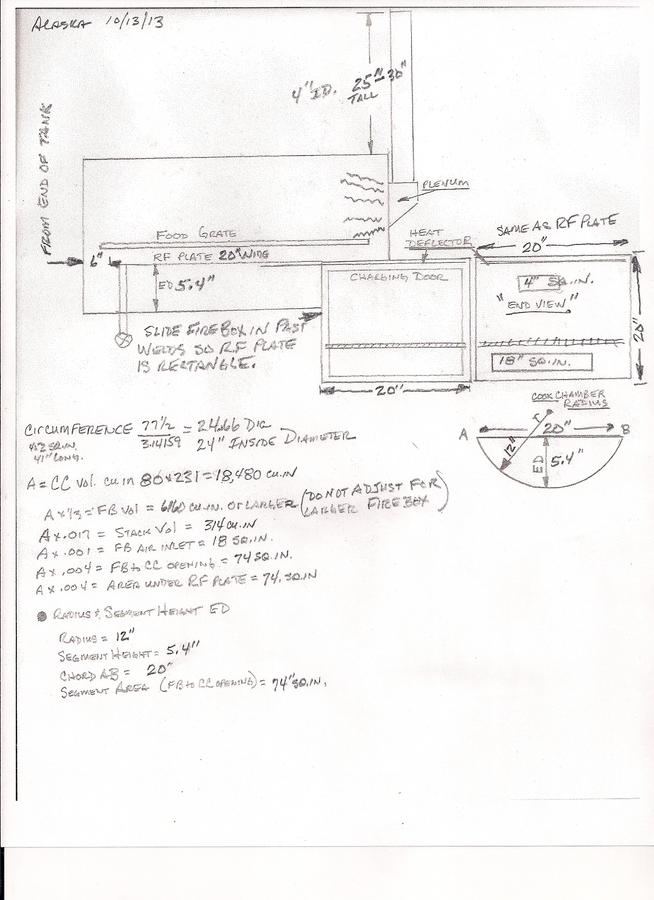

Ok here is the problem Somehow I got my figures mixed up and made my firebox to big! According to Feldon's pit calculator now I cant get the FB to CC opening big enough. It recommends 110.59"sq and for me to have 5" between cook surface and RF plate I can only get around 76" sq. Even if I move RF plate up to only 3" below cook surface I still only bump opening up to about 100" sq. But would you want RF plate that close?

Here are my numbers.. any help would be greatly appreciated.

All I have done so far is cut door in tank ( bottom of door is at widest point of tank) and built firebox (all but door piece is welded in place with grate and ash box in bottom)

It being a RF is not set in stone

80 gal tank 24"X46"

Firebox - 24"X24"X24"