Update, with pics.

Was able to do a little more work on Saturday, as the weather was a little warmer.

Completed the cooking grates.

I scored a piece of "shaker grate" from a good friend. These are used in gravel pits to sort out rocks. The rocks came included! This will be incorporated into the firebox grating.

I also scored some used but heavy duty caster wheels for the pit from another good friend. It sure is nice to have good friends.

And then came the dilemma; I had planned on using my skid-steer loader to lift up the pit to install legs and get it mounted to the frame. However, it is in the shop and will be there for a few weeks. So, we had to improvise. We rigged 2 cum-a-longs to the frame of my lean-to to lift it up using the u-bolts that were installed for this and future purposes. However, we could not lift it quite high enough; we were lacking 4 inches. So we welded some steel to one side of the pit and the other to the rf plate and started lifting. The pit was rolling on us and I knew that I needed it top-center level. We then added temporary u-bolts to the top end centers of the chamber and were able to lift it to height. I know that a lot of people use car engine cherry pickers, but I don't know anyone who has one. I haven't seen much posting about lifting the barrel to put it on the stand, so I was really winging it.

I ran into the true learning curve; how to get the darn legs onto the pit and onto the stand, and have it all fit right with the right angles and such. Most of the posts I've seen show the beginning of the stand and then the pit is on the stand. It took a long time, a LONG time! But, finally figured it out and it will be so much easier next time.

So, finally I have a pit on wheels.

You can see that I extended the stand to go under the firebox. I had thought I would mount the firebox to the pit at the rf plate and then put legs under the fb to the stand. There would be no structural support intended and no wheels under that section. So I think I will cut it back and cap the ends. It is not necessary and I think that long stand looks too much like a sled. Also, I plan to use a floor jack to lift that heavy fb box up to weld and the stand would be in the way for that.

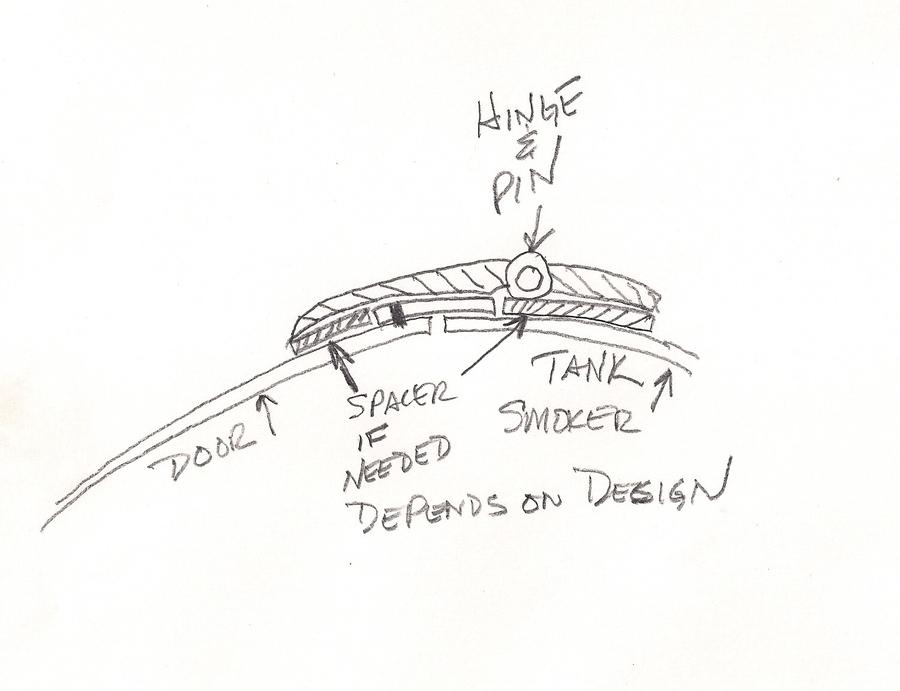

Can someone please help answer a chimney stack volume question? I am thinking about installing the chimney on the end cap, above the firebox so that it doesn't get in the way of the doors. I am probably not going to use a plenum unless I have to, so I thought that I would come out of the side of the wall horizontally for 3-4 inches, have it cut at 90 degrees, and then turn upwards to the required height. So the question; does that horizontal part count as volume? It will take up about 40+ inches of volume. And doing it that way, is the vertical part the calculation, or is it once it gets up above the cc? Any help would be appreciated. Thanks

Keith