thanks for rletting me know that makes sense. So let me ask how thick should the RP be? does it even have to be thick or would just plain ol sheet metal do?

first rf build with a question

- Thread starter bigsmoken

- Start date

-

Some of the links on this forum allow SMF, at no cost to you, to earn a small commission when you click through and make a purchase. Let me know if you have any questions about this.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

SMF is reader-supported. When you buy through links on our site, we may earn an affiliate commission.

So does anyone know how thick the rf plate should be....gonna be getting it within a week and would like to price out from different places

smokejumper

Smoking Fanatic

Thank you sir I'll go for the 1/4 if I can. also can I infer that it is a good thing to have the rf plate at a bit of an angle? the higher side being the hole at the rfp

Last edited:

smokejumper

Smoking Fanatic

There should be a slope leading down to a grease drain. Check several of the builds on here for some of the different drain locations and designs.

Laddies and gentelfolk...GET READY....I have been paid and have not been found wanting as I have gotten and been blessed with a WELDER from the wonderful fok of harbor freight and I shall run (not walk) Run to the metal dealer tomorrow and take onto me his blessing of metal and continue the build from which I started. Of course there shall be merryment and photos. I also recieved a huge wonderful meat grinder from which I shall produce a wide array of sausage....Holly crap....That was a mouthful. lol

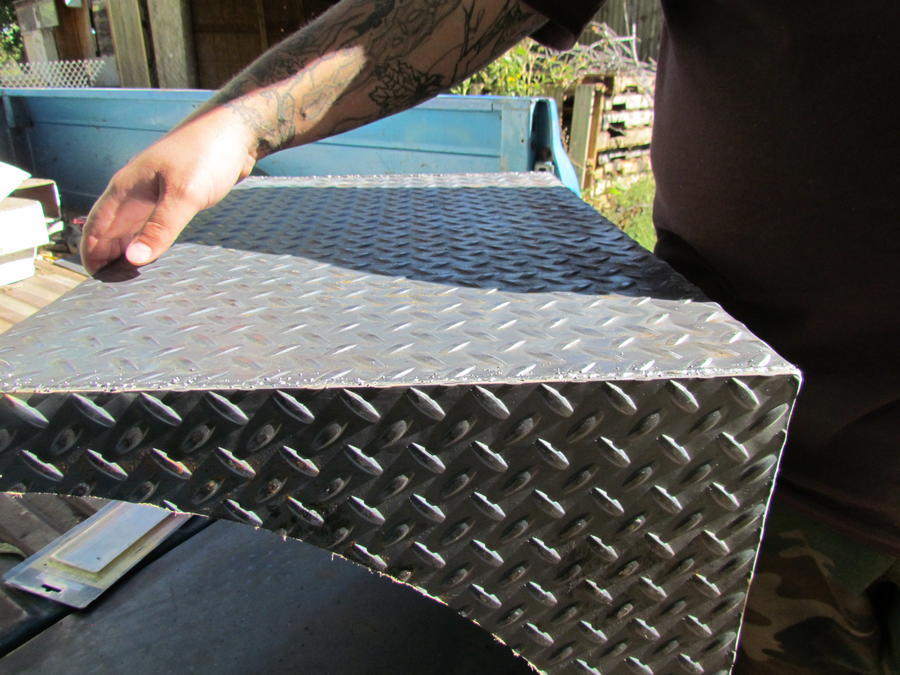

Here is the side view...I still have to kinda shape it so it sits closer to the tank

kinda of a side top view...as you can see I used diamond plate...pretty

here is one of my welds...I'm kinda proud of it...I got it done with years inbetween welding.

So I went to my local metal place and got this diamond plate for 80 bucks and I still have enough to do the front of the firebox so that will look a bit pretty as well. I do have to admit that I was thinking of using a thicker metal so that way it dosent let heat through so quick and I got three sixteenth thickness and um....its kinda heavy. Just saying.

yeah thats the thickness I was gonna use....I figgure the thicker it is the more heat it is gonna hold and let go of.

Ok so next question...I was thinking of making it so I can tow it behind the truck for competitions but I dont want to put it on a trailer trailer because I'll have to put it where I dont want it....so my question is this...I'm gonna build it onto a stand with trailer qualities such as a hitch but I was thinking I want to put either car tires or truck tires on it so how would I build the axle on it to accodmodate such a small width...or would I want to make it a free wheel kinda thing. no axle. any ideas on this would help tremendously as I'm kinda stuck as to how to do this part.

smokejumper

Smoking Fanatic

The thing that immediately popped into my mind was those towable cement mixers they have for rent.

Some have a narrow wheel spacing, so I don't see a problem building something like that.

A leaf spring axle can be shortened by cutting and re-welding back together.

Some have a narrow wheel spacing, so I don't see a problem building something like that.

A leaf spring axle can be shortened by cutting and re-welding back together.

ribwizzard

Master of the Pit

I agree, look at those tow able mixers for your proportions, your hitch could be square tubing that slides into a larger piece of square tubing and held in place with a hitch pin. Take a look at log splitters too, they are tow able, but compact as well.

might be the wrong place to bring this up, but what the heck. What do you pit gurus think about using diamond plate facing down for the RF plate, maybe a compromise on the fins thing? or not enough turbulence to really do any good?

doug

doug

I think I'll check it out....I'm looking for something that I can use around here...in my town. For being a rural town you'd think that someone would have something...yeesh

I have tried....but to no avail...i think I want to do like some metal wagon wheels on the backend and maybe a stand or some smaller wheels up front...I think the plan is to make the frame for it all but just put it on cinder blocks untill I can come up with what i want..I'm putting enough money into this that I want what I want but I want to find a good deal. Anyway by putting it on blocks and having the frame ready for the wheels I can at least keep building on it while i wait for the right wheels..and Once im finshed with it I can cook on it...its not gonna go anywhere for about a year anyways...and I think that I'll just trailer it when it does have to go.

I was thinking of building my own but I'm wanting pretty big ones...I was hoping to have no legs when putting on the wagon wheels...big ones.....I'll check it out though....thank you

next question fellow builder..fire box...I picked up the start of it and got a 1/4 steel plate for the back. I was gonna use some of the 3/16 diamond plate for the front...is that thick enough? or do I need to stay with the 1/4.

SmokingMeatForums.com is reader supported and as an Amazon Associate, we may earn commissions from qualifying purchases.

Similar threads

- Replies

- 20

- Views

- 2K

- Replies

- 5

- Views

- 2K

- Replies

- 4

- Views

- 1K

- Replies

- 34

- Views

- 3K

Hot Threads

-

PRO 100 SPARES

- Started by sawhorseray

- Replies: 29

- Pork

-

Featured Plate Ribs Tonight

- Started by schlotz

- Replies: 28

- Blowing Smoke Around the Smoker.

-

What do if yiy have too many peaches??? Make dessert of course!

- Started by 02ebz06

- Replies: 23

- General Discussion

-

Trying some new BBQ sauces with some heat (I hope)

- Started by sandyut

- Replies: 22

- Blowing Smoke Around the Smoker.