First I should introduce myself I'm Derrick from upstate ny and have been looking threw the build threads here for a while built a double barrel smoker last winter and learned a lot using that and decided I wanted to build a reverse flow. A freind of mine owns a small junk yard and I found a old co2 tank in his yard was mounted to somthing at one time not sure what though. It's 200 gas 1/4 inch wall according to the tag. I do some repair work on cars he is selling and yard equipment and instead of asking for money he always takes care of me when I need something in the yard so the tank was free. I also picked up a wood stove a friends brother had that cost me a 30 rack of beer so 25 bucks. The doors have a couple small cracks but it should work fine for a fire box. If I cut the bump up on the top off its the just a little larger then the calculator called for and it's also made of 1/4 inch steel. I now need to find a trailer I have some creative ideas to try on that when I get one. so far i have 25 bucks invested plus diesel to go get them so far so good let me know what ya think good bad or indifferent.

200 gal reverse flow build

- Thread starter symonds86

- Start date

-

Some of the links on this forum allow SMF, at no cost to you, to earn a small commission when you click through and make a purchase. Let me know if you have any questions about this.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

SMF is reader-supported. When you buy through links on our site, we may earn an affiliate commission.

need a lil help the calculator says 17 inch halfmoon cut for the chamber to the tank does that 17 inches wide at the top?

Send DaveOmak a PM here is his profile. http://www.smokingmeatforums.com/u/40430/DaveOmak He will be more than happy to help you with your build. He does great drawings.need a lil help the calculator says 17 inch halfmoon cut for the chamber to the tank does that 17 inches wide at the top?

Happy smoken.

David

munxcub

Smoke Blower

Or use the circle calculator he has in his sig line. There was a post I saw not long ago where he explained how to use it too. You can use it to figure out the proper area you need, and how high up you tank to cut and stuff.

Symonds, evening.... Can you post the dimensions of the tank on here..... circumference, length between the welds on the dome ends, and overall length.... those numbers will give me a good idea of the size of the tank... I know the tag says, 200 gal gas but at times they factor in a dead space volume that is to allow for expansion... I will then do up a preliminary set of numbers for a RF smoker for you....

Please take a moment and stop into " [color= rgb(146, 144, 139)]/[/color][color= rgb(128, 0, 0)]Roll Call[/color][color= rgb(146, 144, 139)]/[/color] " and introduce yourself and get a proper welcome from our members.... Also, if you would note your location in your profile, it will help in the future when answering questions about smokin'... elevation, humidity etc....

We're glad you stopped in and joined our group... Enjoy the long smokey ride.... Dave

Please take a moment and stop into " [color= rgb(146, 144, 139)]/[/color][color= rgb(128, 0, 0)]Roll Call[/color][color= rgb(146, 144, 139)]/[/color] " and introduce yourself and get a proper welcome from our members.... Also, if you would note your location in your profile, it will help in the future when answering questions about smokin'... elevation, humidity etc....

We're glad you stopped in and joined our group... Enjoy the long smokey ride.... Dave

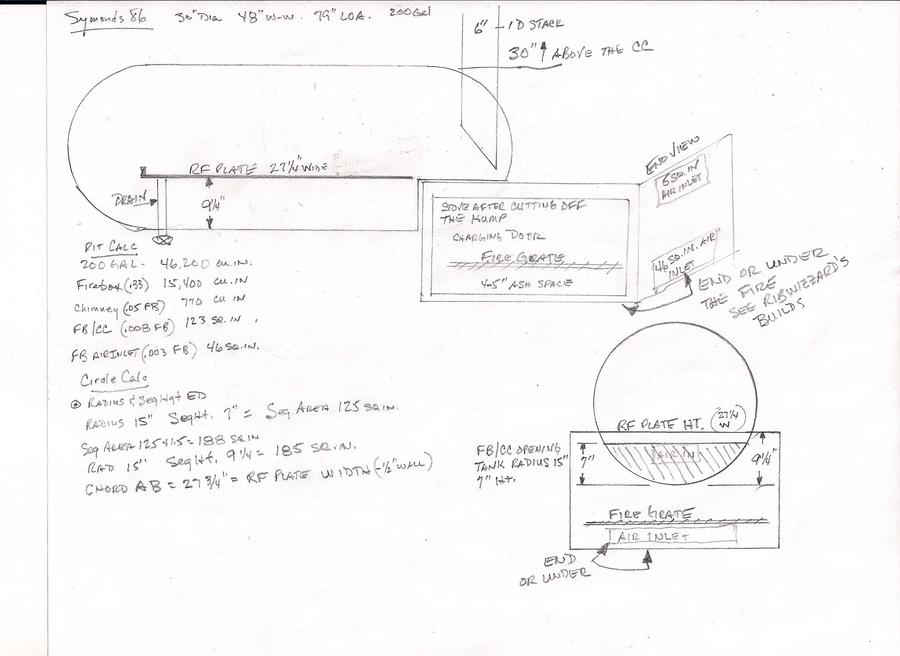

thanks for the welcome i will stop in at roll call after this post the tank is 30 in diameter, 48 inches weld to weld and 6ft 7in end to end so roughly 15.5 inches from each end from the welds to the end of the domes

Thanks dave. I will be watching as well. I still wish you knew wood boilersSymonds, evening.... Can you post the dimensions of the tank on here..... circumference, length between the welds on the dome ends, and overall length.... those numbers will give me a good idea of the size of the tank... I know the tag says, 200 gal gas but at times they factor in a dead space volume that is to allow for expansion... I will then do up a preliminary set of numbers for a RF smoker for you....

Please take a moment and stop into " /Roll Call/ " and introduce yourself and get a proper welcome from our members.... Also, if you would note your location in your profile, it will help in the future when answering questions about smokin'... elevation, humidity etc....

We're glad you stopped in and joined our group... Enjoy the long smokey ride.... Dave

Happy smoken.

David

I can see the smile in your face while you are typing. DaveOmakthanks for the welcome i will stop in at roll call after this post the tank is 30 in diameter, 48 inches weld to weld and 6ft 7in end to end so roughly 15.5 inches from each end from the welds to the end of the domes

Happy smoken.

David

i will do my best to keep pics coming as i make progress and thanks dave for helpin me with the numbers

Here's a start.......... That should make a pretty good smoker.... Dave

............. click on pic to enlarge .............

............. click on pic to enlarge .............

thanks dave your number s are about the same as i came up with but the rf measurement, the half moon measurement help a ton as well thanks again i will try to get some pics this weekend when i start working on it

i have a couple more questions for my rf plate i was goin to use 2 pieces of 1/4 inch with a 1/4x2 angle in the middle but i would like to just make 1 piece of 1/4 inch the correct size for the entire rf plat and then put it in the press break and give it a slight crease in the middle for the drain would this affect the function? also my stove im using for a fire box has fire brick lining it should i remove them or just the ones i need to for the outlet and vents? thanks in advance

Press brake is fine.... easier to install, cheaper, less welding, water tight....But the 1 piece is heavy...try for a 1" valley or so... 1" in 15" is a good slope....... remove only the necessary firebrick...

You can tack weld in the RF plate.... not necessary for full welds...1/2" bead every 12" would work... as heavy as it will be, it ain't going no where... with the crease, it will only expand downward....

The "v" formed in the RF plate will tack right up to the 2 1/4" space in the firebox between the FB/CC cutout and the top of the FB...

Dave

You can tack weld in the RF plate.... not necessary for full welds...1/2" bead every 12" would work... as heavy as it will be, it ain't going no where... with the crease, it will only expand downward....

The "v" formed in the RF plate will tack right up to the 2 1/4" space in the firebox between the FB/CC cutout and the top of the FB...

Dave

its a kodiak stove the doors have a couple cracks and the baffles inside are burned out so i dont feel to bad cutting it up lol

dave i have a couple more questions first off my moth on the fire box was way off so instead of cutting the hump off i will raise the top to the height of the hump giving me 24 height 27 wide 24 tall 15552 cu in but i will have to mount it with the charge door to the back in order to have the width i need will this be ok. also how far into the cc should the fb go? and how big a gap between the end of the rf and the end of the tank? thanks

To make fit up easy for the RF plate, insert the FB to the weld around the tank.... that's where it straightens out and the RF plate can then be a rectangle..... You can stop the RF plate at the weld seam at the other end....

SmokingMeatForums.com is reader supported and as an Amazon Associate, we may earn commissions from qualifying purchases.

Similar threads

- Replies

- 0

- Views

- 3K

- Replies

- 4

- Views

- 770

- Replies

- 49

- Views

- 5K

- Replies

- 14

- Views

- 1K

Hot Threads

-

PRO 100 SPARES

- Started by sawhorseray

- Replies: 29

- Pork

-

Featured Plate Ribs Tonight

- Started by schlotz

- Replies: 28

- Blowing Smoke Around the Smoker.

-

What do if yiy have too many peaches??? Make dessert of course!

- Started by 02ebz06

- Replies: 23

- General Discussion

-

Trying some new BBQ sauces with some heat (I hope)

- Started by sandyut

- Replies: 22

- Blowing Smoke Around the Smoker.