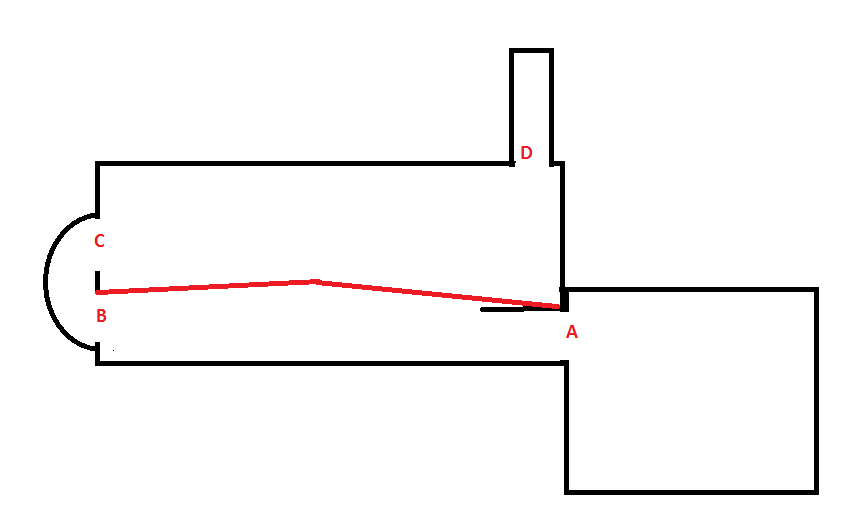

Below is a simple drawing of my current build. Generally, I don't "choke down" any of the letter designated areas, but totally rely on air intake and well sealed up chambers to control heat, ..but in this build I'm thinking of choking down "B" opening, trapping more heat under the reverse flow plate, and opening up "C" and "D" as to create very little resistance. My thought is more cooking heat with less pressure in the cooking chamber to help create more of the "open pit" style of BBQ. Letting the smoke just freely linger by.

Any thoughts???....

Any thoughts???....