Dave,

Okay, if I understanding you, you think a centrally located burner would be better? I agree 100%, there was no practical way for me to achieve this with what I had on hand. I was gonna mount the burner from the back, but that create an awkward location for the control!? I may still do this? As far as a 2nd 'heat shield' I already had that planned as I was gonna use a 1/2 sheet x 2"D steam table pan for chips...

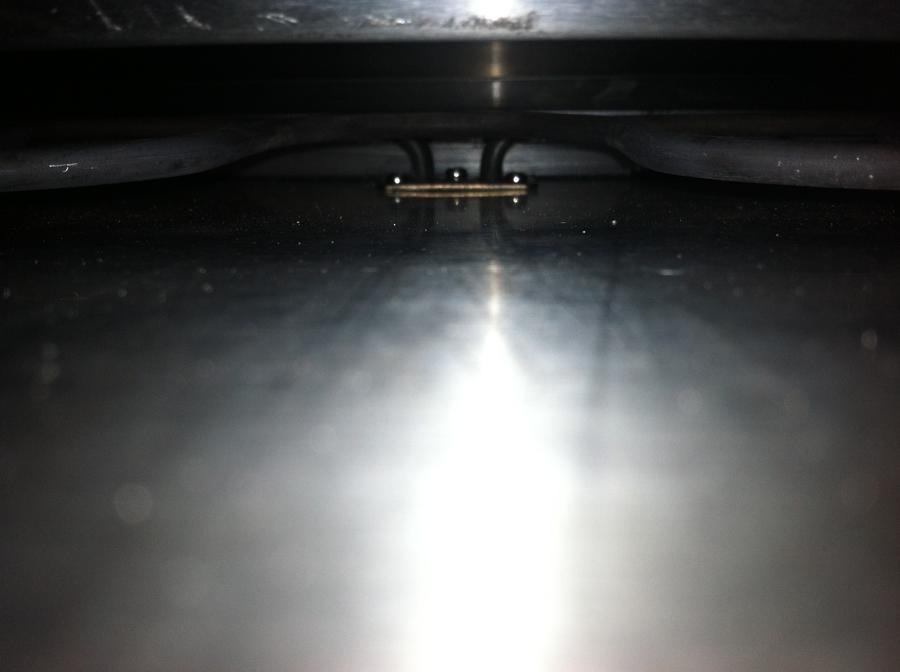

Like this one--->

I'm aware that one side will be hotter than the rest; however, I plan on using that to my advantage? by rotating meat?

I also would like to have a double wall with some form of insulation between. I like your idea of riveting it too the shelving brackets (Side Note: There was only the one bracket that it came with, I bought some 1" x 1" aluminum angle for new shelving supports, if I make a new interior 'skin' then I could bolt them directly too?) This project is a minimum invest type deal, so we'll see on that. I know most of the cheaper smokers are single wall thin gauge CRS...this one is a little thicker (hell, even thicker than Frank's skin, but he has 2 layers and insulation between). It most likely won't hold heat ideally, but it might get the job done?

Another note I found out cruising the internet is the RVQ2 burner is only 12,000BTU...even the cheaper "Smoke Hollow" has a 15,200BTU burner. Not sure of cubic inches though? It'll be hot for sure on the exterior, but no hotter than my NBBD nor my gas grill I used on my deck?!

As I said, I'll run her up the flag pole and see what flys? I get the idea it'll be a constant tinker type project making subtle improvements trying to get her dialed in?! If you remember Frank's mods, I'm a try it an see what happens kinda guy.

Oh yeah, my new exhaust stack...I'll make a dampner or get a 90* ell...it's 1 1/2 chromed brass sink tail piece...The coupler is galvanized (I know, I know?) But many years ago I used to be an iron worker (short summer, I was actually a machinist) I got zinc posioning from puddle welding galvanized decking on a bridge we were building...never been so sick! You'd have to get the galvanized metal hot enough to melt the zinc coating and that is 787.15*F...if I'm hitting those temps we got a problem!!!

Exhaust:

I'll keep this thread updated as I make more changes!