Ok guys, and gals. Im preparing to get this tank mounted on the trailer for fabrication time. I was hoping I could get some ideas from you guys. Like if I should run 1 or 2 doors? Whats the best way to keep the door(s) in line when cutting? thanks.....

SmokinWelders First Smoker Ever!!!! 250 gallon/trailer build

- Thread starter smokinwelder

- Start date

-

Some of the links on this forum allow SMF, at no cost to you, to earn a small commission when you click through and make a purchase. Let me know if you have any questions about this.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

SMF is reader-supported. When you buy through links on our site, we may earn an affiliate commission.

themidniteryder

Smoke Blower

To keep the door gap as tight, straight, and neat as possible I would use a 12 or 14" cutoff saw. Believe it or not a masonry wheel will last longer cutting steel than a steel wheel will. Cut the top first, weld on the hinges, then cut the other 3 sides. At least thats the plan when I cut my doors. Tack you a handle for someone to hold before you cut the final inch, otherwise the door will try and fold in on you making it a pain to get out and possibly bend the hinge. I would go with 2 doors and plan on counter weights, unless you plan on doing a whole hog. Then 1 door with counter weight and maybe a spring assist. If you are planning slid out grates, one door will have you a LONG grate which will have to be built out of heavier material resulting in greater overall trailer weight as well as harder to slide out.

Dont fret.......Im back on the build. I know its been a bit, but here we go. Most of the trailer is done, so I started on the tank. I started cutting the door all but the corners and the middle. The door allready wants to spring open........I am going to weld the hinges on the tank, and door first before I complete the corner cuts. But I scared to finish the cuts!!! Any advice on keeping its shape?!!!! I also cut the firebox to cooker hole.......Any advice is appreciated. Thanks, Smokin!

Last edited:

rasimmo

Meat Mopper

I would probably just cut it and fix it after you see how bad it is. Another option would be get in it and weld something vertically on the inside of the door. Not sure that is necessary or even possible.

caublecustomfab

Smoke Blower

brian deckard

Newbie

Where is the plasma cutter???????? Ha ha

Liking good I can remember when I was in your stage of build. Ill send pic if I can figure it out

Liking good I can remember when I was in your stage of build. Ill send pic if I can figure it out

lol, plasma cutters at the shop. tanks at home.....cutting wheels working better than I thought acually. I am going to weld hindges on tomm, and finish cutting door........wish me luck!

I got some done today! Its so hard trying to provide for a family, and find time with so many different projects going on. But today i did find time....(right before the sun went down), to get my hindges welded on and door cut. I am very impressed on how the door kept its shape! I was told that these hindges will not work due to having to add the door trim, but I see plenty room. Feels good to have gotten this far. I have a lot of work ahead of me. Thank you all for all the advice.

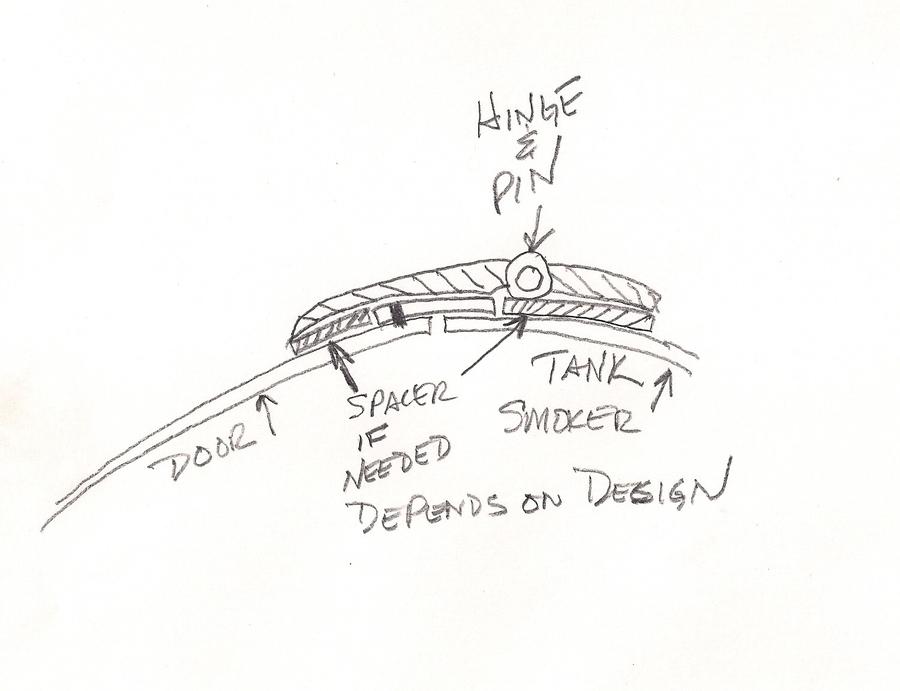

I hope when you open the door, the top seal doesn't hit he tank... when trying to close the door, the top seal might hit the tank... the pivot should have been moved back,more toward the tank, past where the seal goes to eliminate that problem.... I sent you a picture with the location of the hinge pin in relation to the seal..... Dave

Last edited:

rasimmo

Meat Mopper

Those hinges look very similar to what I have planned. Did you center the bolt above the cut? If so the flange may drag when you try to open it. If it is behind the cut then it will lift up and not drag. It's hard to tell from the angle of the pic. I'm on a phone so it ain't very big.

What size plate and bolt did you use? I am thinking of using 1/4" plate and 1/2" bolts.

Looks like Dave was having the same thought at the same time.

What size plate and bolt did you use? I am thinking of using 1/4" plate and 1/2" bolts.

Looks like Dave was having the same thought at the same time.

Last edited:

I hope when you open the door, the top seal doesn't hit he tank... when trying to close the door, the top seal might hit the tank... the pivot should have been moved back,more toward the tank, past where the seal goes to eliminate that problem.... I sent you a picture with the location of the hinge pin in relation to the seal..... Dave

yeah Dave Im a keep it simple stupid kinda guy. Did you look at how high and far away the top seal would be from the cc? I think you might be a little too old school for what the up and comming bbq present may have to precure. I appriciate all the advice, but as a fabricator/welder please dont try to tell my my hindges wont work. Take notes "buddy". There is an expression, out with the old, in with the new......better luck next time. Rasimmo check your pm's buddy......Smokin.Those hinges look very similar to what I have planned. Did you center the bolt above the cut? If so the flange may drag when you try to open it. If it is behind the cut then it will lift up and not drag. It's hard to tell from the angle of the pic. I'm on a phone so it ain't very big.

What size plate and bolt did you use? I am thinking of using 1/4" plate and 1/2" bolts.

Looks like Dave was having the same thought at the same time.

Rasimmo what "flange" are you speaking of? check your pm"s.up and comming,

Last edited:

smokinwelder.... I apologize for answering your questions for the last 6 weeks... all the PM's.... phone calls..... and all the drawings.....

My mistake.....

My mistake.....

Last edited:

themidniteryder

Smoke Blower

NOT a good way to make friends in here. As a "Fabricator/Weldor" (and yes weldor is the person performing the welding) you shouldn't have to ask how to keep the tank from rusting any more, what size metal to use for the frame, how to cut an axle and the tank, how to keep the door from springing when you make the final cuts....and several other questions. Design, yes, I can understand asking questions. But basic metal working that a second year apprentice should know? You asked for help and advice. Folks in here answered your call with advice that comes with years of experience. And then you come back with an attitude like that? I would venture to guess you are on your own from here on out "buddy".....you might can lay a bead, but a fabricator/weldor you ain't. This is the nice draft......I would get banned if I said what I really wanted to.yeah Dave Im a keep it simple stupid kinda guy. Did you look at how high and far away the top seal would be from the cc? I think you might be a little too old school for what the up and comming bbq present may have to precure. I appriciate all the advice, but as a fabricator/welder please dont try to tell my my hindges wont work. Take notes "buddy". There is an expression, out with the old, in with the new......

stovebolt

Smoking Fanatic

That was rude! Just my opinion.yeah Dave Im a keep it simple stupid kinda guy. Did you look at how high and far away the top seal would be from the cc? I think you might be a little too old school for what the up and comming bbq present may have to precure. I appriciate all the advice, but as a fabricator/welder please dont try to tell my my hindges wont work. Take notes "buddy". There is an expression, out with the old, in with the new......better luck next time. Rasimmo check your pm's buddy......Smokin.

Rasimmo what "flange" are you speaking of? check your pm"s.up and comming,

Chuck

capntrip

Smoking Fanatic

Yeah it was rude. I apologize dave. I was having a bad night and too many drinks last night. Sorry man. Youve given me good advice. I appologize to the other members too.

mr big d

Fire Starter

Dave

Please don't quit or slow down on your posts to help the fellow smoker, Even Theo I don't ask directly for all the times i may need assistance I am learning from every time you post for someone else, with all your knowledge is vary valuable information for me and a lot of other good people on this forum.

Keep up the good work.

Please don't quit or slow down on your posts to help the fellow smoker, Even Theo I don't ask directly for all the times i may need assistance I am learning from every time you post for someone else, with all your knowledge is vary valuable information for me and a lot of other good people on this forum.

Keep up the good work.

NOT a good way to make friends in here. As a "Fabricator/Weldor" (and yes weldor is the person performing the welding) you shouldn't have to ask how to keep the tank from rusting any more, what size metal to use for the frame, how to cut an axle and the tank, how to keep the door from springing when you make the final cuts....and several other questions. Design, yes, I can understand asking questions. But basic metal working that a second year apprentice should know? You asked for help and advice. Folks in here answered your call with advice that comes with years of experience. And then you come back with an attitude like that? I would venture to guess you are on your own from here on out "buddy".....you might can lay a bead, but a fabricator/weldor you ain't. This is the nice draft......I would get banned if I said what I really wanted to.yeah Dave Im a keep it simple stupid kinda guy. Did you look at how high and far away the top seal would be from the cc? I think you might be a little too old school for what the up and comming bbq present may have to precure. I appriciate all the advice, but as a fabricator/welder please dont try to tell my my hindges wont work. Take notes "buddy". There is an expression, out with the old, in with the new......

:yeahthat: X2

Yeah it was rude. I apologize dave. I was having a bad night and too many drinks last night. Sorry man. Youve given me good advice. I appologize to the other members too.

So then your saying your a "Nasty Drunk" ?

SmokingMeatForums.com is reader supported and as an Amazon Associate, we may earn commissions from qualifying purchases.

Similar threads

- Replies

- 245

- Views

- 13K

- Replies

- 3

- Views

- 3K

- Replies

- 1

- Views

- 2K

- Replies

- 2

- Views

- 2K

- Replies

- 321

- Views

- 19K

- Replies

- 1

- Views

- 2K

- Replies

- 1

- Views

- 1K

Hot Threads

-

Spammer PMs, Anybody Else?

- Started by chilerelleno

- Replies: 66

- Blowing Smoke Around the Smoker.

-

Lost my dad yesterday

- Started by normanaj

- Replies: 40

- Blowing Smoke Around the Smoker.

-

On the Edge of Trying Sausage Making

- Started by BrianGSDTexoma

- Replies: 35

- Sausage

-

Took a stroll this afternoon

- Started by Buckeyedude

- Replies: 33

- Field and Stream

-

Featured Blackened Rockfish...

- Started by Gonna Smoke

- Replies: 33

- Fish