Hi All,

I have begun my first Reverse Flow smoker build.

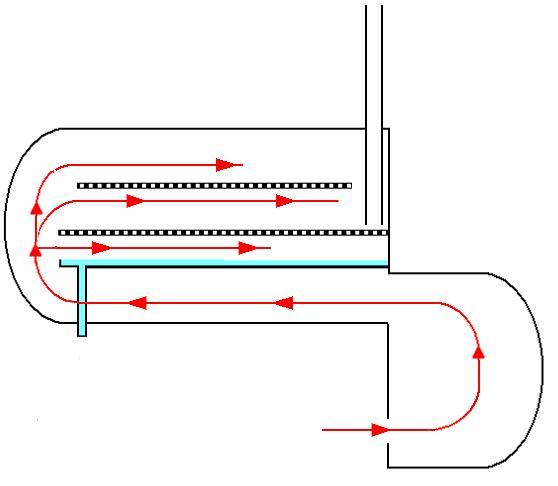

I am using a 125-Gallon propane tank. The tank is 24" diameter and approx 64" long (averaging the domed ends). I took advantage of the calculator and worked out the dimensions pretty well (I think). I traced the fire box to smoke box opening out on paper and overlaid a 1" grid to verify my numbers were correct. I am in the process of cutting the fire box and smoke box end plates. I wanted to throw my design thoughts out there to see what sticks to the wall (so to speak).

I am not tucking the fire box up under the smoke box because it will limit my access to tend the fire. (I plan to cut the fire box door in the upper side of the fire box as opposed the end because the end is domed and will not be easily accessable to me once mounted in place. I know I will have heat loss, but will the loss be enough to worry about?

My air inlet will be on the lower left side of the fire box with a handle to easily adjust. My stack will be 6" X 2" rectangle which will give me roughly the same area as a 4" round stack.

This is my numbers per the calculator:

Length of Tank 64”

Cooker Chamber Size 48” of Tank - 21700 cubic inches

Firebox Size 16” of Tank - 7240 cubic inches

Firebox Intake Vents 1 ½” X 3” X 5 Vents

Smokebox Opening 5 3/4” - 60 square inches

Chimney Pipe Size 2” X 6” @32” above Smoke Box

RF Plate Opening 90 square inches

Any and all ideas and critique (constructive, of course) is welcomed.

Thanks

I have begun my first Reverse Flow smoker build.

I am using a 125-Gallon propane tank. The tank is 24" diameter and approx 64" long (averaging the domed ends). I took advantage of the calculator and worked out the dimensions pretty well (I think). I traced the fire box to smoke box opening out on paper and overlaid a 1" grid to verify my numbers were correct. I am in the process of cutting the fire box and smoke box end plates. I wanted to throw my design thoughts out there to see what sticks to the wall (so to speak).

I am not tucking the fire box up under the smoke box because it will limit my access to tend the fire. (I plan to cut the fire box door in the upper side of the fire box as opposed the end because the end is domed and will not be easily accessable to me once mounted in place. I know I will have heat loss, but will the loss be enough to worry about?

My air inlet will be on the lower left side of the fire box with a handle to easily adjust. My stack will be 6" X 2" rectangle which will give me roughly the same area as a 4" round stack.

This is my numbers per the calculator:

Length of Tank 64”

Cooker Chamber Size 48” of Tank - 21700 cubic inches

Firebox Size 16” of Tank - 7240 cubic inches

Firebox Intake Vents 1 ½” X 3” X 5 Vents

Smokebox Opening 5 3/4” - 60 square inches

Chimney Pipe Size 2” X 6” @32” above Smoke Box

RF Plate Opening 90 square inches

Any and all ideas and critique (constructive, of course) is welcomed.

Thanks

Last edited: