Hello everyone,I am planning my first tank build.I already have the 250 gallon tank and a couple trailers to work with. Tank dimension's are 71" seam to seam,91 " total length .30" wide.and 93 1/4" Circumference.

I am not sure where to cut the door in height. I have read a lot of threads, but i want to be sure.I was thinking 12 and 3

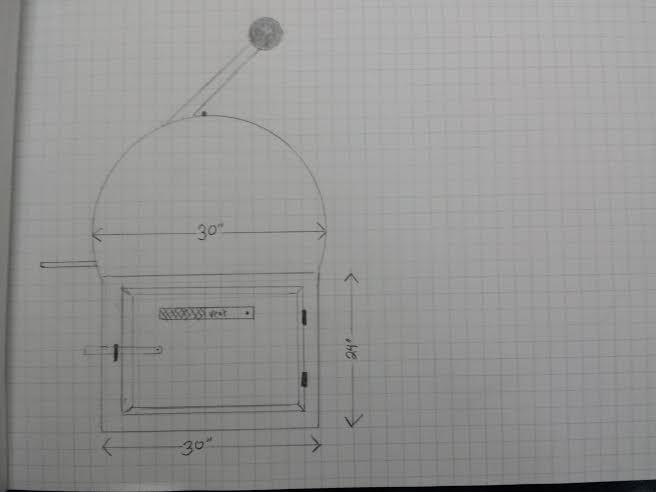

Will the cooking grate be ok 6" above the RF plate?.Are there any concerns/problems with the drawings below?

I am not sure where to cut the door in height. I have read a lot of threads, but i want to be sure.I was thinking 12 and 3

Will the cooking grate be ok 6" above the RF plate?.Are there any concerns/problems with the drawings below?