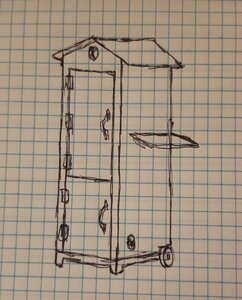

Looking for some input on my smoker design.

First of all, I'm a DIYer and I don't weld, so I've been working on an idea for a wood sided smoker. I'm also cheap, so I'm trying to be as efficient as possible with as little materials as possible.

Here are some details on the plan:

-I found a plywood at Home Depot with a soy based glue, so there's none of the extra added nasty stuff. I've seen some varying opinions on if this even matters, but I've got three kids 4 years and under, so I'd rather just not take a chance.

-Using two sheets of plywood, I can make it about 6' tall, with inside dimensions of about 2'x2'.

-My primary heat/smoke source is a small charcoal grill. Kind of like a mini Weber. That will go in the lower section.

-I'll also going to add ports to give me some versatility. I'd like the option in the future to use an electric or propane burner. And I'm going to have another to attach a stove pipe for cold smoke.

-The inside of the structure will be lined with cement board for heat retention.

-Adjustable vents at the peaks at the front and back for smoke and one on each side at the bottom for air intake.

-I want it to be easily portable, so there will be wheels to move it like a hand cart.

-Dowels and grill grates will be adjustable through the entire height of the upper section.

-A piece of cement board can be used inside as a baffle if I need to shrink the size of the smoke chamber for any reason.

-There will be a shelf to the side

I feel like everything should work the way it should, but dimensions are my biggest concern. Is 2'x2' big enough for things like full racks of ribs, briskets, and turkeys? Would I be better off making it wider than it is deep? I could also do 2.5'x1.5' or anywhere between without having to buy a third sheet of plywood.

Please pick this thing apart and let me know if there are any details I might not have though of. I've been re-engineering this thing over and over for a long time, but I just don't have the smoking experience to know how practical my ideas are.

First of all, I'm a DIYer and I don't weld, so I've been working on an idea for a wood sided smoker. I'm also cheap, so I'm trying to be as efficient as possible with as little materials as possible.

Here are some details on the plan:

-I found a plywood at Home Depot with a soy based glue, so there's none of the extra added nasty stuff. I've seen some varying opinions on if this even matters, but I've got three kids 4 years and under, so I'd rather just not take a chance.

-Using two sheets of plywood, I can make it about 6' tall, with inside dimensions of about 2'x2'.

-My primary heat/smoke source is a small charcoal grill. Kind of like a mini Weber. That will go in the lower section.

-I'll also going to add ports to give me some versatility. I'd like the option in the future to use an electric or propane burner. And I'm going to have another to attach a stove pipe for cold smoke.

-The inside of the structure will be lined with cement board for heat retention.

-Adjustable vents at the peaks at the front and back for smoke and one on each side at the bottom for air intake.

-I want it to be easily portable, so there will be wheels to move it like a hand cart.

-Dowels and grill grates will be adjustable through the entire height of the upper section.

-A piece of cement board can be used inside as a baffle if I need to shrink the size of the smoke chamber for any reason.

-There will be a shelf to the side

I feel like everything should work the way it should, but dimensions are my biggest concern. Is 2'x2' big enough for things like full racks of ribs, briskets, and turkeys? Would I be better off making it wider than it is deep? I could also do 2.5'x1.5' or anywhere between without having to buy a third sheet of plywood.

Please pick this thing apart and let me know if there are any details I might not have though of. I've been re-engineering this thing over and over for a long time, but I just don't have the smoking experience to know how practical my ideas are.